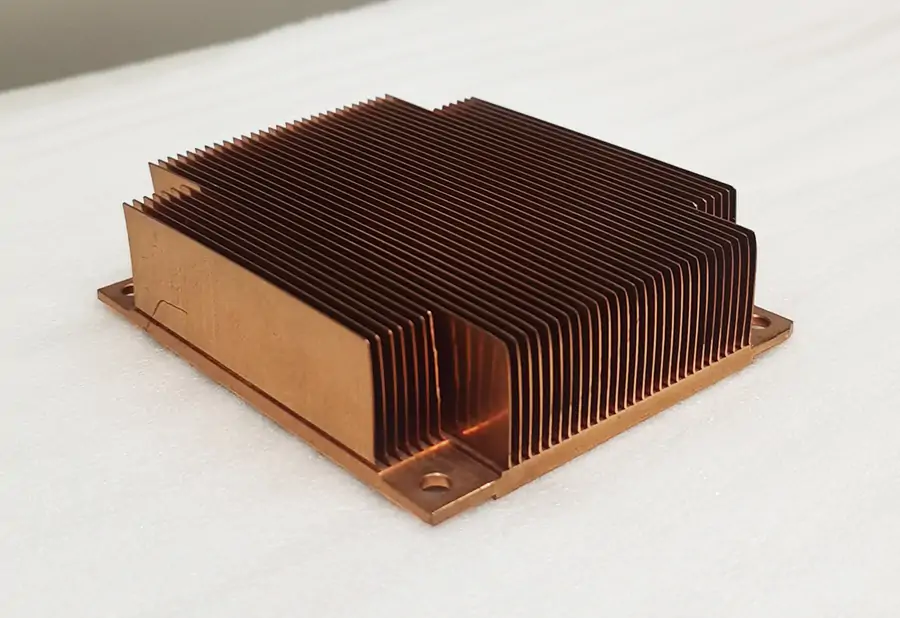

Brief Overview of Copper Heatsinks and Their Importance in Thermal Management Solutions

As electronic devices advance, efficient thermal management solutions are crucial for optimal performance and longevity. Copper heatsinks play a vital role in dissipating heat generated by components, ensuring stability and preventing overheating. With high thermal conductivity and effective heat dissipation capabilities, copper heatsinks outperform other materials in various applications.

Introduction to Xuiron as a Professional Heatsink Manufacturing Company

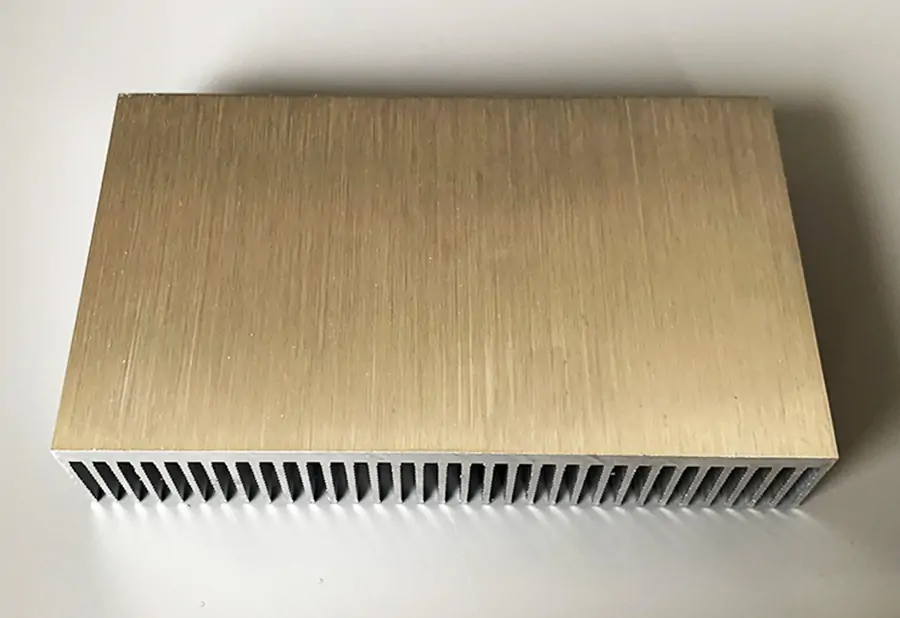

Specializing in customized extruded heatsinks and shovel tooth heatsinks, Xuiron is a leading manufacturer based in Hebei Province, China. Their products, made from pure aluminum or copper, boast faster heat conduction and better heat dissipation. Xuiron's commitment to customer satisfaction, cost-effectiveness, and high efficiency makes them a top choice in the heatsink industry.

Copper Heatsinks: An Efficient Heat Conduction and Dissipation Solution

When it comes to thermal management solutions, copper heatsinks play a crucial role. In this section, we will delve into the properties of copper as a material for heatsinks, compare its advantages and trade-offs with other materials, and explore the applications of copper heatsinks across various industries.

Properties of Copper as a Material for Heatsinks

Copper is an excellent choice for heatsinks due to its high thermal conductivity and exceptional heat dissipation capabilities. Its high thermal conductivity allows it to efficiently transfer heat from the source to the heatsink, while its excellent heat dissipation capabilities enable the heatsink to efficiently spread and dissipate the heat into the surrounding environment. These properties make copper heatsinks highly effective in maintaining optimal operating temperatures for electronic components and systems.

Comparison of Copper Heatsinks with Other Materials (e.g., Aluminum)

While aluminum is another common material used for heatsinks, copper offers certain advantages. Copper heatsinks have a higher thermal conductivity than aluminum, which results in more efficient heat transfer and dissipation. However, there are some trade-offs and considerations when choosing a heatsink material. Copper is denser and more expensive than aluminum, making it heavier and potentially increasing costs. Ultimately, the choice of material depends on factors such as budget, weight constraints, and desired performance levels.

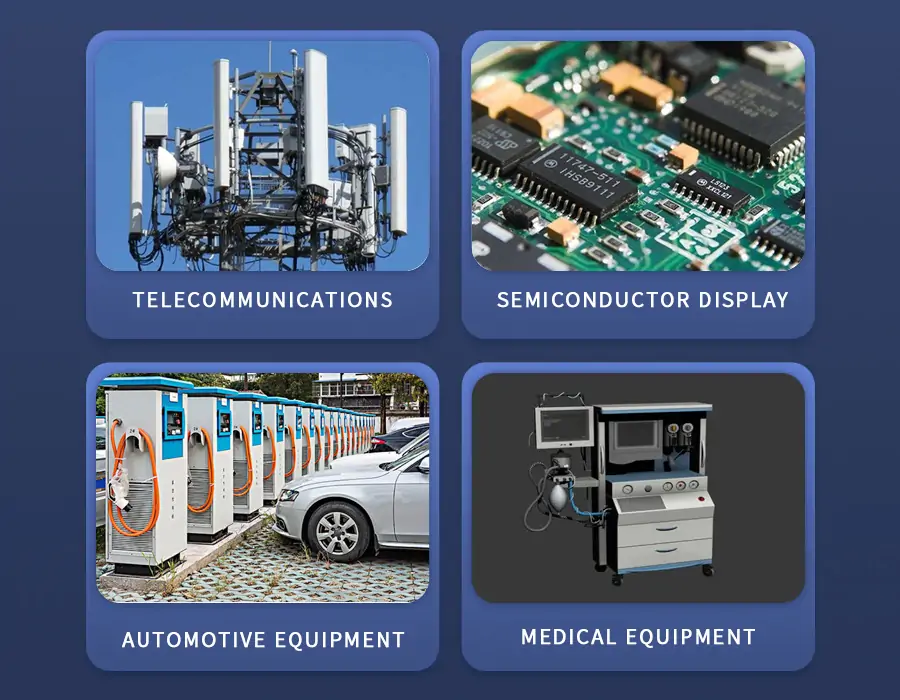

Applications of Copper Heatsinks in Various Industries

The effectiveness of copper heatsinks has led to their widespread use across a range of industries. Some of these industries include:

- Network communications: Copper heatsinks help maintain optimal operating temperatures for routers, switches, and other networking equipment, ensuring efficient data transmission and reducing the risk of thermal-related failures.

- Medical care: In medical devices like MRI machines and diagnostic equipment, copper heatsinks play a vital role in ensuring temperature stability and preserving the integrity of sensitive components.

- Artificial Intelligence and Internet of Things: With the increasing complexity and power requirements of AI and IoT devices, copper heatsinks are crucial for maintaining thermal stability and optimizing performance.

- Automotive electronics: In electric vehicles and other automotive systems, copper heatsinks help manage heat generated by power electronics, ensuring reliability and longevity.

- Semiconductor displays: In display technologies like OLED and microLED, copper heatsinks help dissipate heat and maintain temperature stability, which is essential for preserving display quality and lifespan.

In summary, copper heatsinks provide an efficient heat conduction and dissipation solution, making them a popular choice for thermal management in various industries. Their high thermal conductivity and excellent heat dissipation capabilities, coupled with their widespread applicability, make them an integral component in optimizing the performance and reliability of electronic systems.

Xuiron's Copper Heatsink Manufacturing Process

In producing high-quality copper heatsinks, Xuiron follows a comprehensive manufacturing process that ensures efficient heat conduction and dissipation. This section will provide an overview of each step involved in the manufacturing process, from material selection to quality inspection.

Material Selection and Cutting

The process begins with the selection of high-quality copper material, which is crucial for the performance and durability of the heatsink. The copper is carefully cut into appropriate sizes and shapes according to the specific design requirements, ensuring optimal heat conduction and dissipation properties.

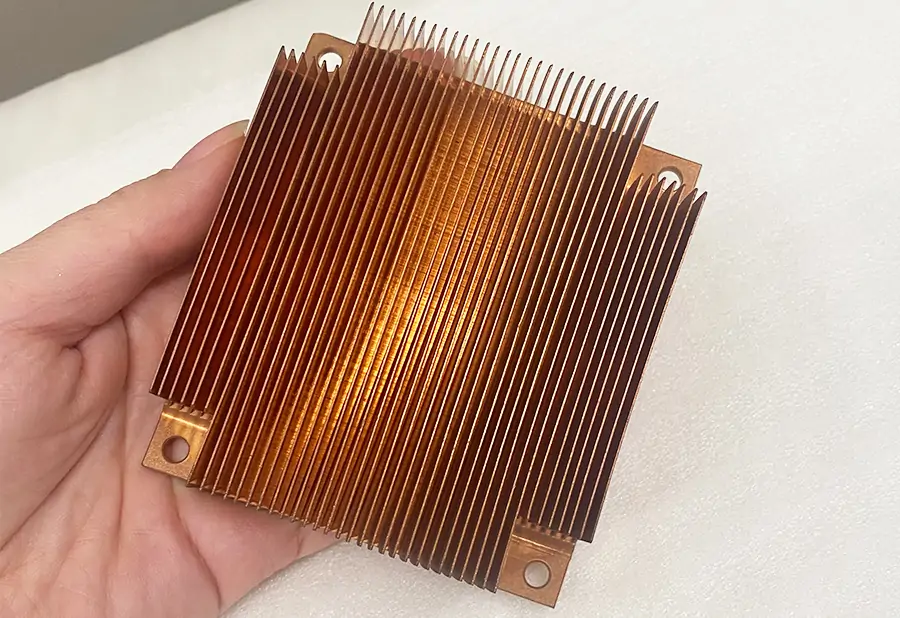

Tooth Shoveling and Hobbing

Next, tooth shoveling and hobbing processes are employed to create the unique heatsink design. These techniques help to improve the heatsink's surface area, thus maximizing heat dissipation efficiency. The tooth shoveling method is particularly useful for producing Xuiron's signature shovel tooth heatsinks, which are known for their excellent performance.

Trimming, Grinding, and CNC Processing

Once the heatsink's structure has been formed, it undergoes trimming and grinding to remove any excess material and ensure a smooth finish. Computer numerical control (CNC) processing is then used to further refine the heatsink's shape, providing high precision and accuracy in its design.

Shaping and Polishing

The shaped heatsink is then polished to enhance its appearance and improve its heat dissipation properties. A smooth, polished surface helps to reduce the buildup of dust and debris, which can negatively impact the heatsink's thermal performance over time.

Anti-Oxidation Treatment

To protect the copper heatsink from oxidation and corrosion, an anti-oxidation treatment is applied. This treatment not only prolongs the life of the heatsink but also maintains its thermal performance, ensuring that it remains effective in heat conduction and dissipation throughout its service life.

Quality Inspection

Finally, each copper heatsink undergoes a strict quality inspection process to ensure that it meets Xuiron's high standards for performance and durability. This process includes testing the heatsink's thermal properties and checking its overall design and appearance for any defects or inconsistencies. Only after passing this thorough inspection can the heatsink be deemed ready for use in various industries and applications.

Customization Options for Copper Heatsinks

One of the key aspects that sets Xuiron apart in the heatsink industry is their ability to provide customized copper heatsinks that cater to specific customer requirements. This process begins with understanding the unique needs and specifications of each customer, which allows the company to develop tailored solutions that maximize heat conduction and dissipation performance.

Understanding Customer Requirements

When approaching a new project, Xuiron's team of experts works closely with the customer to gain a thorough understanding of the application and its thermal management needs. This includes considering factors such as the type of device, the operating environment, and any constraints related to size, weight, or material compatibility. By taking these factors into account, Xuiron can develop a customized solution that meets the exact needs of the customer.

Designing and Engineering Custom Solutions

Once the customer requirements have been identified, Xuiron's skilled engineers begin the process of designing and engineering a copper heatsink solution that fulfills those specifications. This may involve modifying existing designs or creating entirely new ones, depending on the unique demands of the application. Throughout this process, Xuiron's team maintains open communication with the customer to ensure that the final product meets all expectations and delivers optimal performance.

Ensuring Efficient Manufacturing Processes

After the design and engineering phase, Xuiron focuses on implementing efficient manufacturing processes to produce the customized copper heatsinks. This involves leveraging state-of-the-art equipment and following strict quality control measures to ensure each heatsink meets the company's high standards for performance and durability. By streamlining the manufacturing process and continuously updating their equipment and techniques, Xuiron is able to provide cost-effective and high-quality copper heatsinks that satisfy the diverse needs of their customers.

Quality Assurance and Inspection

In the world of copper heatsinks, maintaining strict quality control measures is essential to ensure efficient heat conduction and dissipation. Xuiron is committed to providing the highest quality products by implementing a comprehensive quality assurance process, which includes multiple steps to guarantee customer satisfaction.

One of the key aspects of Xuiron's quality control process is the use of enhanced packaging for product protection. By using thickened cartons and wooden boxes, the company ensures that the copper heatsinks arrive in perfect condition, ready to meet the high-performance demands of various industries.

In addition to strict quality control measures and enhanced packaging, Xuiron is dedicated to continuous learning and equipment updates. By staying on the cutting edge of manufacturing technology and industry best practices, the company is able to deliver cost-effective and high-quality copper heatsinks that meet the evolving needs of their customers. This constant pursuit of improvement also allows Xuiron to stay ahead of competitors and maintain its position as a leading provider of professional heatsink solutions.

In summary, Xuiron's commitment to quality assurance and inspection is evident in the strict quality control measures, enhanced packaging, and continuous learning and equipment updates they employ. These factors, combined with their dedication to customer satisfaction, make Xuiron an ideal choice for those in need of high-quality, efficient copper heatsinks.

Customer Satisfaction and Service

At Xuiron, customer satisfaction is of utmost importance, and the company takes various measures to ensure that its clients receive top-notch service. One of the ways they achieve this is by committing to delivering products according to specified schedules. This dedication to punctuality demonstrates that Xuiron values its customers' time and aims to meet their thermal management needs as efficiently as possible.

In addition to timely deliveries, Xuiron offers various shipping options to cater to the preferences and requirements of its diverse clientele. By providing multiple shipping methods, the company ensures that customers can select the most convenient and cost-effective solution for their needs.

Furthermore, Xuiron maintains transparency in its payment and production lead time information. Customers can make payments using the TT payment method, and the company provides an estimated production lead time based on the order details. This transparency enables clients to plan their projects effectively and manage their expectations regarding the delivery of their copper heatsink solutions.

In conclusion, Xuiron's commitment to customer satisfaction and service is evident in its punctual deliveries, versatile shipping options, and transparent payment and production lead time information. These measures collectively contribute to a seamless and positive experience for clients seeking efficient and high-quality copper heatsink solutions.

Conclusion

In conclusion, copper heatsinks have proven to be an efficient heat conduction and dissipation solution due to their high thermal conductivity and excellent heat dissipation capabilities. These properties make them a superior choice for a wide range of industries, including network communications, medical care, artificial intelligence, Internet of Things, automotive electronics, and semiconductor displays.

Xuiron, a professional heatsink manufacturing company, demonstrates its expertise and capabilities in producing high-quality copper heatsinks. Through a rigorous manufacturing process and commitment to customer satisfaction, Xuiron ensures that their copper heatsinks meet the strictest quality standards and are tailored to the specific needs of their clients. As a result, businesses across various industries can rely on Xuiron's copper heatsinks to provide efficient and effective thermal management solutions.

Discover Xuiron Solutions

As we have explored the benefits of copper heatsinks and Xuiron's expertise in manufacturing high-quality solutions, it's time to take action. With their advanced manufacturing processes and commitment to customer satisfaction, Xuiron is your go-to choice for efficient and reliable thermal management.

Visit Xuiron's Official Website

Get more information about their products and services at xuiron.com .

Contact for Inquiries or Quotes

Reach out to Xuiron to discuss your requirements and request a quote for customized solutions tailored to your needs.