High-quality extruded heatsinks play a critical role in modern electronics, providing efficient thermal management to ensure optimal performance and longevity of electronic components. As the demand for advanced and reliable thermal solutions increases, Xuiron, a professional heatsink manufacturing company, specializes in delivering customized extruded heatsinks tailored to specific applications and industries.

Extruded Heatsink Manufacturing Process

The manufacturing process of extruded heatsinks is a vital aspect in ensuring their high-quality performance. This process consists of several essential steps, as detailed below.

Material Selection and Cutting

The first step in the extruded heatsink manufacturing process is selecting the appropriate materials. Pure aluminum or copper is commonly used due to their excellent thermal conductivity properties. After choosing the material, it is cut into the desired shape and size, setting the stage for the subsequent steps.

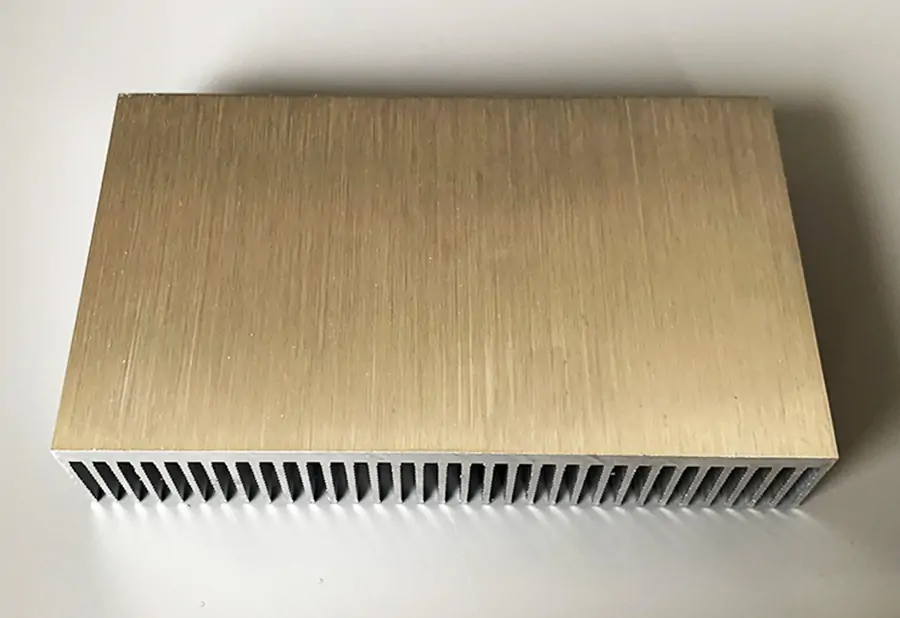

Tooth Shoveling and Hobbing

Next, the material undergoes tooth shoveling and hobbing. Tooth shoveling involves the removal of excess material to create the desired heatsink profile. Hobbing, on the other hand, is a cutting process that forms the teeth or fins of the heatsink, providing the necessary surface area for efficient heat dissipation.

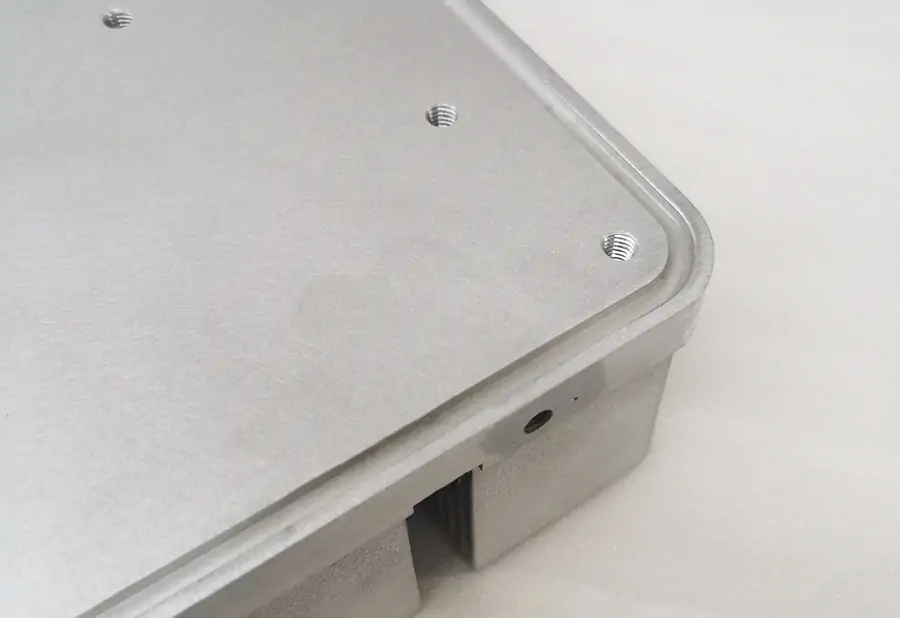

Trimming, Grinding, and CNC Processing

Following tooth shoveling and hobbing, the extruded heatsink is further refined through trimming and grinding processes. Trimming ensures that the heatsink has a uniform shape and size, while grinding smooths the surface to eliminate any rough edges. CNC processing is then employed to create intricate features and customize the heatsink according to the specific application requirements.

Shaping, Polishing, and Anti-Oxidation Treatment

Once the heatsink has been trimmed, ground, and CNC processed, it is shaped to fit the intended application precisely. Polishing is then performed to give the heatsink a smooth and shiny appearance, enhancing its aesthetics and functionality. To prevent oxidation and ensure long-lasting performance, the heatsink is subjected to anti-oxidation treatment, typically involving anodizing or other protective coatings.

Quality Inspection and Packaging

The final step in the extruded heatsink manufacturing process is quality inspection. Each heatsink is meticulously examined to ensure it meets the stringent quality standards set by the manufacturer. After passing the inspection, the heatsinks are carefully packaged using thickened cartons or wooden boxes to guarantee safe transportation to customers.

Main Features of Xuiron's Extruded Heatsinks

The quality of an extruded heatsink plays a crucial role in ensuring optimal performance in various electronic applications. Xuiron's extruded heatsinks stand out due to their superior features, which include:

Faster Heat Conduction

One of the main features of Xuiron's extruded heatsinks is their ability to conduct heat rapidly. This is essential in preventing overheating in electronic devices, allowing them to function efficiently and prolonging their lifespan.

Better Heat Dissipation

Besides faster heat conduction, Xuiron's extruded heatsinks are designed to dissipate heat effectively. This helps maintain a stable temperature in electronic devices, ensuring consistent performance and preventing potential damage caused by excessive heat.

Pure Aluminum or Copper Material

Xuiron's extruded heatsinks are made from pure aluminum or copper, which are known for their excellent thermal conductivity properties. These materials ensure efficient heat transfer and dissipation, making them ideal for a wide range of applications.

Customization Options for Various Applications

To cater to the diverse needs of different industries, Xuiron offers customization options for their extruded heatsinks. This enables customers to choose the most suitable heatsink design and material for their specific applications, ensuring optimal performance and longevity of their electronic devices.

Advantages of Extruded Heatsinks

Extruded heatsinks offer several significant benefits for various applications in the electronics industry. These advantages include a cost-effective manufacturing process, enhanced thermal performance, flexible design and customization options, and lightweight yet durable construction.

Cost-effective Manufacturing Process

Extrusion is a cost-effective manufacturing process for creating heatsinks, as it allows for the production of complex shapes and profiles with minimal waste. This efficient method results in lower production costs, making extruded heatsinks an attractive option for businesses seeking to optimize their budgets.

Enhanced Thermal Performance

Extruded heatsinks provide enhanced thermal performance due to their design and material properties. The high surface area of the fins improves heat dissipation, while the use of pure aluminum or copper materials ensures excellent heat conduction. This combination ensures that extruded heatsinks effectively manage heat in electronic devices, preventing overheating and improving reliability.

Flexible Design and Customization

Extruded heatsinks offer flexibility in design and customization, allowing manufacturers to create heatsinks tailored to specific applications and requirements. This adaptability ensures that extruded heatsinks can be used across a wide range of industries and products, including network communications, medical care, artificial intelligence, automotive electronics, and semiconductor displays.

Lightweight and Durable Construction

The lightweight and durable construction of extruded heatsinks make them ideal for use in various electronic devices. Aluminum and copper materials provide both strength and lightness, ensuring that the heatsinks do not add excessive weight to the devices they are used in. This durability ensures that extruded heatsinks can withstand the demands of modern electronics, providing long-lasting performance and reliability.

Applications of Extruded Heatsinks in Various Industries

The versatility and efficiency of extruded heatsinks make them suitable for a wide range of industries. By maintaining optimal thermal performance, they contribute to the overall performance and reliability of electronic devices. Let's explore some key industries where extruded heatsinks play a crucial role:

A. Network Communications Extruded heatsinks are essential for ensuring the smooth functioning of network communication devices such as routers, switches, and servers. They help dissipate heat generated by high-speed processors and other electronic components, preventing overheating and potential malfunctions in the system.

B. Medical Care In the medical industry, extruded heatsinks are employed in various devices like medical imaging equipment, patient monitoring systems, and laboratory instruments. They help maintain the stability and accuracy of these devices by effectively managing the heat produced during operation.

C. Artificial Intelligence and Internet of Things As the demand for AI and IoT devices grows, the need for efficient thermal management becomes more critical. Extruded heatsinks are used in smart home systems, robotics, wearables, and other connected devices to ensure their longevity and optimal performance by keeping the temperature within safe limits.

D. Automotive Electronics With the rapid advancement in automotive technology, vehicles now feature numerous electronic systems, such as infotainment systems, navigation, and advanced driver assistance systems (ADAS). Extruded heatsinks are vital in maintaining the performance and safety of these systems by effectively managing the heat generated during operation.

E. Semiconductor Displays Extruded heatsinks are widely used in the semiconductor industry, particularly in LED displays and other electronic display systems. They help prolong the lifespan of these systems by effectively dissipating the heat generated by the electronic components, ensuring consistent performance and reducing the risk of damage due to overheating.

Xuiron's Commitment to Customer Satisfaction

At the core of Xuiron's business is their unwavering dedication to customer satisfaction. This commitment is demonstrated through various aspects of their operations, including a strict quality inspection process, enhanced packaging for safe transportation, continuous learning and equipment updates, and timely delivery and efficient manufacturing processes.

Strict Quality Inspection Process

Xuiron recognizes the importance of delivering high-quality extruded heatsinks that meet their customers' expectations. To ensure this, they have implemented a rigorous quality inspection process that examines every detail of the heatsink, from its material and construction to its thermal performance and durability. This meticulous approach helps guarantee that the final product meets the required standards and specifications.

Enhanced Packaging for Safe Transportation

Understanding the potential risks associated with transporting delicate electronic components, Xuiron prioritizes safe and secure packaging for their extruded heatsinks. By using thickened cartons and wooden boxes, they minimize the chances of damage during transportation, ensuring that the heatsinks arrive in perfect condition and ready for use.

Continuous Learning and Equipment Updates

Keeping up with the latest advances in extrusion technology and manufacturing techniques is vital for maintaining a competitive edge in the heatsink industry. Xuiron invests in continuous learning and equipment updates to stay ahead of the curve, providing their customers with the most advanced, cost-effective, and high-quality extruded heatsinks available on the market.

Timely Delivery and Efficient Manufacturing Processes

Recognizing the importance of efficient manufacturing processes and timely delivery, Xuiron aims to deliver their products according to the specified delivery schedule. Their streamlined operations, coupled with a commitment to meeting deadlines, ensure that customers can rely on them for their heatsink requirements without any delays or disruptions.

Comparing Extruded Heatsinks with CNC Machined Heatsinks

When deciding on a heatsink manufacturing method, it's essential to understand the differences between extruded heatsinks and CNC machined heatsinks. This section will provide an overview of both processes, compare their efficiency and cost, and discuss their suitability for different applications.

Overview of CNC machining and extrusion processes

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to cut away material, resulting in a desired part shape. On the other hand, extrusion is a process that involves pushing a heated material, such as aluminum, through a die to create a continuous profile with a specific cross-sectional shape.

Extruded heatsinks are made by forcing the aluminum through a die to create a continuous profile with fins and other desired features. CNC machined heatsinks are created by removing material from a solid block of aluminum or other materials using cutting tools to shape the desired form.

Efficiency and cost comparisons

In terms of efficiency, extruded heatsinks offer a more cost-effective manufacturing process compared to CNC machined heatsinks. The extrusion process allows for mass production of heatsinks with consistent quality, resulting in lower per-unit costs. CNC machining, while capable of producing intricate designs, tends to be more expensive due to the time-consuming nature of the process and the need for skilled operators.

However, it's essential to consider the specific requirements of your project when choosing between the two manufacturing methods. For complex designs or low-volume production, CNC machining might be a more suitable option, despite its higher costs. On the other hand, extruded heatsinks are a better choice for high-volume production and simpler designs.

Suitability for different applications

Extruded heatsinks are well-suited for applications that require a high level of thermal performance and demand cost-effective manufacturing. They are commonly used in industries such as network communications, medical care, artificial intelligence, automotive electronics, and semiconductor displays. Their lightweight and durable construction make them ideal for these applications.

CNC machined heatsinks are more appropriate for applications that demand intricate designs or have specific requirements that cannot be met by the extrusion process. For example, aerospace and defense industries often require CNC machined heatsinks due to their unique requirements and need for precision. Ultimately, the choice between extruded and CNC machined heatsinks depends on your project's specific needs and goals.

Best Practices for Choosing and Designing Extruded Heatsinks

When selecting and designing extruded heatsinks for your project, it is crucial to consider the following factors:

Determining the required thermal performance

Start by calculating the necessary thermal performance to ensure the heatsink can effectively dissipate heat and maintain the desired temperature for your electronic components. Consider factors such as ambient temperature, airflow, and the heat generated by the device. Ensuring that the heatsink provides adequate thermal performance will help extend the life of your electronic components and improve overall efficiency.

Selecting appropriate materials

Material selection plays a significant role in the performance of extruded heatsinks. Common materials include aluminum and copper, each offering distinct advantages. Aluminum is lightweight, cost-effective, and offers good thermal conductivity. Copper, on the other hand, has better thermal conductivity but is heavier and more expensive. Choose the material that best suits your application and budget requirements.

Customization options for specific applications

Extruded heatsinks can be customized to meet the unique requirements of your project. Take into account the size, shape, and mounting options that best suit your application. Additionally, consider any specific design features or enhancements, such as surface treatments or coatings, that can improve thermal performance and durability. By tailoring the heatsink to your particular needs, you can optimize its efficiency and effectiveness in your project.

Conclusion: The Future of Extruded Heatsinks in Electronics

The demand for high-quality heatsinks is continuously growing as modern electronics become more advanced and require efficient thermal management. Extruded heatsinks play a crucial role in maintaining the performance and longevity of electronic components. As this demand increases, the extrusion technology is expected to evolve and innovate, further enhancing the efficiency and effectiveness of extruded heatsinks.

One key factor driving the future of extruded heatsinks in electronics is the ongoing innovation and development in extrusion technology. This includes improvements in the manufacturing process, materials, and design capabilities, enabling the production of even more efficient and cost-effective extruded heatsinks. These advancements will allow manufacturers to meet the growing demand for high-quality, customized heatsinks in various industries, such as network communications, medical care, artificial intelligence and Internet of Things, automotive electronics, and semiconductor displays.

Xuiron, as a professional heatsink manufacturing company, is committed to providing cost-effective and high-quality extruded heatsinks. With a focus on customer satisfaction, the company continually strives to enhance its manufacturing processes, quality inspection, packaging, and delivery. This dedication to excellence ensures that Xuiron remains at the forefront of the extruded heatsink industry, providing cutting-edge solutions for today's electronics and meeting the future demands of an ever-evolving market.

Call to Action

Having explored the benefits and applications of extruded heatsinks in various industries, it is clear that high-quality extruded heatsinks play a crucial role in modern electronics. To meet your specific requirements and ensure optimal thermal performance, consider partnering with a professional heatsink manufacturer like Xuiron.

A. Contact Xuiron for inquiries or to request a quote

Xuiron's team of experts is dedicated to providing cost-effective and high-quality extruded heatsinks, tailored to your specific needs. Reach out to Xuiron for any inquiries or to request a quote, and their team will be more than happy to assist you in finding the perfect solution for your thermal management needs. Visit their website at https://xuiron.com to get started.

B. Explore Xuiron's wide range of extruded heatsinks and accessories

Beyond their customized extruded heatsinks, Xuiron also offers a wide range of accessories and related products to enhance the performance and longevity of your electronic devices. Browse through their product offerings at https://xuiron.com/accessories/ and discover the various options available to support your thermal management needs.

Explore Xuiron's Solutions

Throughout this blog, we have discussed the significance of high-quality extruded heatsinks in modern electronics, the manufacturing process, main features, advantages, applications, and the factors to consider when choosing and designing extruded heatsinks. Xuiron, a professional heatsink manufacturing company, specializes in customized extruded heatsinks and shovel tooth heatsinks, offering efficient manufacturing processes, strict quality inspection, enhanced packaging, and excellent customer satisfaction. With their commitment to providing cost-effective and high-quality heatsinks, Xuiron is the perfect partner for your heatsink needs. To learn more about their products or to request a quote, visit https://xuiron.com today.