Are you struggling to find effective cooling solutions for your electronic devices? Look no further. In this comprehensive guide, we will explore the power of pin fin heatsinks and how they can optimize the cooling performance of your devices.

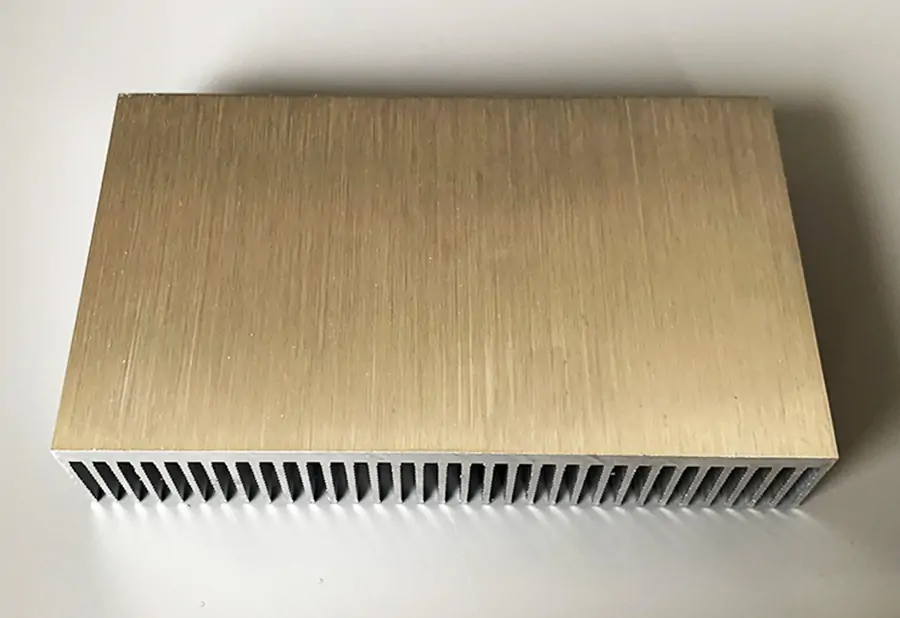

Pin fin heatsinks are specially designed to increase the surface area for heat dissipation, making them an ideal choice for applications that require efficient thermal management. With their unique pin-like structures, these heatsinks maximize airflow and enhance heat transfer, ensuring your devices stay cool even under high temperature conditions.

In this article, we will delve into the science behind pin fin heatsinks, exploring their design principles,materials, and manufacturing techniques. We will also discuss the various factors to consider when selecting a pin fin heatsink for your specific cooling needs.

Whether you are an electronics enthusiast, an engineer, or a product designer, understanding the benefits and applications of pin fin heatsinks is essential for efficient thermal management. Unlock the power of pin fin heatsinks and take your cooling solutions to the next level.

How pin fin heatsinks work

Pin fin heatsinks are specially designed to increase the surface area for heat dissipation, making them an ideal choice for applications that require efficient thermal management. With their unique pin-like structures, these heatsinks maximize airflow and enhance heat transfer, ensuring your devices stay cool even under high temperature conditions.

Pin fin heatsinks work on the principle of convective heat transfer. As the name suggests, these heatsinks feature a large number of small, closely spaced pins that protrude from a base plate. These pins are responsible for increasing the surface area available for heat dissipation. When the heat generated by the electronic components is transferred to the heatsink, the pins provide numerous channels for the heat to escape into the surrounding air.

The high surface area of pin fin heatsinks allows for better heat dissipation compared to other types of heatsinks. The increased surface area facilitates greater contact with the ambient air, enabling efficient cooling.Additionally, the compact design of pin fin heatsinks allows for easy integration into various devices, making them a popular choice in industries such as electronics, telecommunications, and automotive.

Pin fin heatsinks are available in various materials, including aluminum and copper. Aluminum heatsinks are lightweight and cost-effective, making them suitable for most applications. Copper heatsinks, on the other hand,offer better thermal conductivity and are often used in high-performance systems where efficient heat dissipation is crucial.

Advantages of pin fin heatsinks over other cooling solutions

Pin fin heatsinks offer several advantages over other cooling solutions, making them a preferred choice for many applications. One of the key advantages is their ability to maximize airflow and enhance heat transfer.The pin-like structures on the heatsink increase the surface area, allowing for efficient dissipation of heat. This results in improved cooling performance and helps prevent overheating of electronic components.

Another advantage of pin fin heatsinks is their compact design. The small size and lightweight nature of pin fin heatsinks make them suitable for applications where space is limited. They can be easily integrated into devices without affecting their overall size or weight.

Furthermore, pin fin heatsinks are highly customizable. The number, size, and spacing of the pins can be adjusted to meet specific cooling requirements. This flexibility allows for better optimization of the cooling performance, ensuring that the heatsink is tailored to the unique needs of the application.

Pin fin heatsinks also offer better reliability and longevity compared to other cooling solutions. The sturdy construction and efficient heat dissipation capabilities of pin fin heatsinks help extend the lifespan of electronic components by preventing thermal damage caused by excessive heat.

Factors to consider when selecting a pin fin heatsink

When selecting a pin fin heatsink for your specific cooling needs, there are several factors to consider. These factors will ensure that the heatsink is suitable for the application and can effectively dissipate the heat generated by the electronic components.

1. Thermal resistance: The thermal resistance of a heatsink determines its ability to transfer heat. Lower thermal resistance indicates better heat dissipation capabilities. It is important to choose a pin fin heatsink with a low thermal resistance to ensure efficient cooling.

2. Surface area: The surface area of the heatsink directly affects its cooling performance. A larger surface area allows for better heat dissipation. Consider the available space and cooling requirements of the application when selecting a pin fin heatsink.

3. Material selection: The choice of material for the heatsink is crucial. Aluminum heatsinks are cost-effective and suitable for most applications. Copper heatsinks offer better thermal conductivity and are ideal for high-performance systems. Consider the thermal conductivity, weight, and cost factors when selecting the material.

4. Airflow: Proper airflow is essential for effective heat dissipation. Ensure that the pin fin heatsink allows for sufficient airflow around the pins. Consider the device's ventilation system and the ambient conditions in which it will operate.

5. Mounting method: The method of mounting the heatsink onto the electronic component is another important consideration. Different applications may require different mounting methods, such as screws, clips, or adhesive thermal pads. Choose a pin fin heatsink that is compatible with the mounting method of your application.

By considering these factors, you can select a pin fin heatsink that is best suited for your cooling requirements and ensures efficient thermal management.

How to calculate the required heat dissipation for your application

Calculating the required heat dissipation for your application is essential to select the appropriate pin fin heatsink. By accurately determining the amount of heat generated by the electronic components, you can choose a heatsink that can effectively dissipate this heat, preventing overheating and potential damage.

To calculate the required heat dissipation, follow these steps:

1. Identify the power dissipated: Determine the power dissipated by the electronic component in watts (W).This information is usually provided in the component's datasheet or technical specifications.

2. Calculate the thermal resistance: Determine the thermal resistance of the electronic component, typically measured in degrees Celsius per watt (°C/W). The thermal resistance indicates how well the component can transfer heat. It can be obtained from the component's datasheet or technical specifications.

3. Calculate the temperature rise: Multiply the power dissipated by the thermal resistance to calculate the temperature rise. This value indicates the increase in temperature that the component will experience due to the power dissipation.

4. Determine the maximum allowable temperature: Identify the maximum allowable temperature for the electronic component. This information is usually provided in the component's datasheet or technical specifications.

5. Calculate the required heat dissipation: Subtract the maximum allowable temperature from the temperature rise calculated in step 3. The result is the required heat dissipation that the pin fin heatsink needs to achieve to keep the component within the safe operating temperature range.

By following these steps and accurately calculating the required heat dissipation, you can select a pin fin heatsink that meets the cooling requirements of your application and ensures efficient thermal management.

Design considerations for effective thermal management with pin fin heatsinks

Effective thermal management with pin fin heatsinks requires careful consideration of various design aspects.By optimizing the design, you can maximize the cooling performance of the heatsink and ensure efficient heat dissipation.

1. Pins per inch (PPI): The density of pins on the heatsink, measured as pins per inch (PPI), plays a crucial role in heat dissipation. Higher PPI values result in greater surface area and better cooling performance. However, higher PPI also increases pressure drop and airflow resistance. Consider the trade-off between cooling performance and airflow resistance when selecting the PPI value.

2. Pin height and diameter: The height and diameter of the pins also impact heat dissipation. Taller and wider pins provide greater surface area, leading to improved cooling performance. However, larger pins may restrict airflow and increase pressure drop. Consider the available space and airflow requirements when determining the optimal pin height and diameter.

3. Base plate thickness: The thickness of the base plate affects the overall heat transfer capabilities of the heatsink. Thicker base plates provide better thermal conductivity, resulting in improved heat dissipation.However, thicker base plates may also increase the weight and cost of the heatsink. Consider the thermal conductivity requirements and overall constraints of the application when selecting the base plate thickness.

4. Fin spacing: The spacing between the pins, also known as fin spacing, affects the airflow and heat dissipation capabilities of the heatsink. Narrower fin spacing increases the surface area and improves cooling performance. However, narrower spacing may also restrict airflow and increase pressure drop. Consider the balance between cooling performance and airflow requirements when determining the optimal fin spacing.

5. Overall dimensions: The overall dimensions of the heatsink should be compatible with the available space in the application. Consider the height, width, and length of the heatsink to ensure proper integration without compromising the functionality or aesthetics of the device.

By considering these design aspects and optimizing the pin fin heatsink design, you can achieve effective thermal management and ensure efficient heat dissipation in your application.

Common challenges and troubleshooting tips for using pin fin heatsinks

While pin fin heatsinks offer excellent cooling capabilities, certain challenges may arise during their usage.Understanding these challenges and having troubleshooting tips can help address any potential issues and ensure optimal performance.

1. Insufficient airflow: Inadequate airflow can hinder the cooling performance of pin fin heatsinks. Ensure that the device's ventilation system allows for sufficient airflow around the heatsink. Consider adding additional fans or improving the ventilation design if airflow is insufficient.

2. Improper mounting: Incorrect installation or improper mounting of the heatsink can impact its cooling effectiveness. Follow the manufacturer's guidelines for proper mounting and ensure that the heatsink is securely attached to the electronic component. Use the recommended mounting method, such as screws, clips, or adhesive thermal pads, to ensure optimal thermal contact.

3. Thermal interface material: The choice and application of thermal interface material (TIM) can significantly affect the thermal conductivity between the electronic component and the heatsink. Ensure that the TIM is applied correctly and is suitable for the specific application. Consider using high-quality thermal compounds or pads to maximize heat transfer.

4. Inadequate heat dissipation: If the pin fin heatsink is not dissipating enough heat, it may result in overheating of the electronic component. Re-evaluate the required heat dissipation calculations and ensure that the selected heatsink meets the cooling requirements of the application. Consider increasing the surface area, adjusting the pin density, or using a heatsink with better thermal conductivity.

5. Thermal management system: Pin fin heatsinks are often used in conjunction with other thermal management solutions, such as heat pipes or fans. Consider the overall thermal management system of the application and ensure that all components work together efficiently to dissipate heat.

By addressing these common challenges and following the troubleshooting tips, you can overcome any potential issues and maximize the cooling performance of pin fin heatsinks in your application.

Case studies showcasing the effectiveness of pin fin heatsinks in different applications

Pin fin heatsinks have been widely used in various applications to optimize thermal management and ensure efficient cooling. Let's explore some case studies that highlight the effectiveness of pin fin heatsinks in different scenarios.

### Case Study 1: Computer processors

Computer processors generate a significant amount of heat during operation, and effective cooling is crucial to prevent overheating and maintain optimal performance. Pin fin heatsinks have proven to be highly effective in cooling computer processors.

In this case study, a high-performance gaming computer was experiencing overheating issues, resulting in frequent system crashes. By replacing the existing heatsink with a pin fin heatsink, the cooling performance was significantly improved. The pin fin heatsink's increased surface area allowed for better heat dissipation,keeping the processor within safe operating temperatures even during intense gaming sessions.

### Case Study 2: LED lighting

LED lighting fixtures often require efficient thermal management to ensure longevity and optimal

performance. In this case study, a commercial lighting manufacturer was facing issues with LED bulbs overheating, leading to reduced lifespan and decreased light output.

By incorporating pin fin heatsinks into the LED bulb design, the heat dissipation capabilities were greatly enhanced. The pin fin heatsinks effectively dissipated the heat generated by the LEDs, resulting in improved reliability and increased lifespan of the bulbs. Additionally, the enhanced cooling performance ensured consistent light output, maintaining the desired lighting levels over an extended period.

### Case Study 3: Automotive electronics

With the increasing complexity of automotive electronics, effective thermal management is crucial to prevent failures and ensure reliable operation. In this case study, an automotive manufacturer was experiencing issues with the overheating of electronic control units (ECUs) in their vehicles.

By integrating pin fin heatsinks into the ECU design, the cooling performance was significantly improved. The pin fin heatsinks efficiently dissipated the heat generated by the ECUs, ensuring reliable operation even under extreme temperature conditions. The enhanced cooling capabilities of the pin fin heatsinks resulted in improved performance and extended lifespan of the automotive electronics.

These case studies illustrate the effectiveness of pin fin heatsinks in different applications, showcasing their ability to optimize thermal management and ensure efficient cooling.

Conclusion: Harnessing the full potential of pin fin

heatsinks for efficient cooling solutions

Pin fin heatsinks offer a powerful and efficient cooling solution for electronic devices that require effective thermal management. With their unique pin-like structures, these heatsinks maximize airflow and enhance heat transfer, ensuring devices stay cool even under high temperature conditions.

In this