CNC processing

Professional CNC processing, support customization according to drawings.

xuiron CNC processing

Aluminum CNC processing

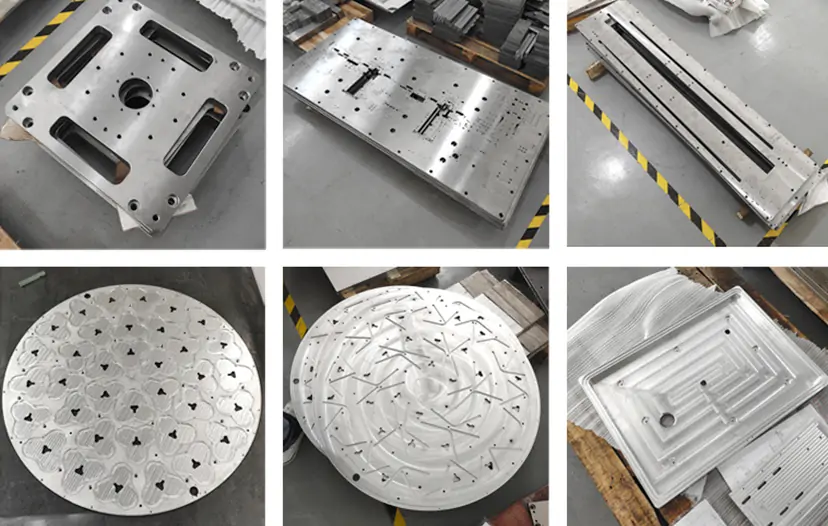

In order to meet the needs of customers, we have developed a CNC machining center, specializing in the production and processing of various precision parts

CNC aluminum and aluminum alloy parts are widely used in various industries due to their fast processing cycle, high manufacturing precision, gorgeous appearance and reproducibility.

xuiron is specially equipped with precision CNC machine tools. Every process such as laser, wire cutting, bending, oxidation, sandblasting, lathe, drilling, and zero cutting is equipped with advanced mechanical equipment to perfectly complete the processing and production of various precision parts. Supports one-piece customization and customization according to pictures.

Constantly updated and iterative Xuiron

In order to ensure the processing quality and precision, we constantly update and iterate CNC machining centers, replace newer and better machines, and provide you with better services.

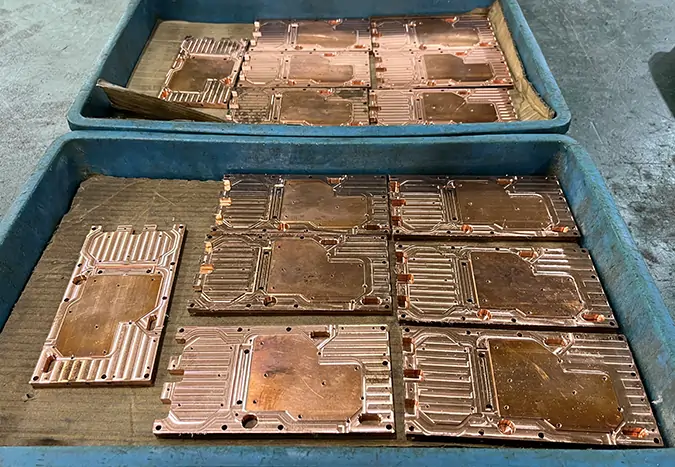

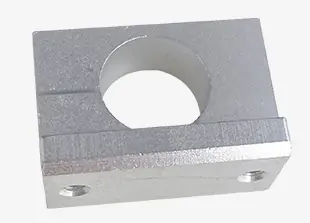

Below are some of the aluminum parts we produce

Request a quote for more details

xuiron CNC processing

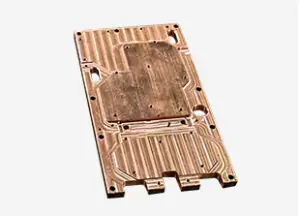

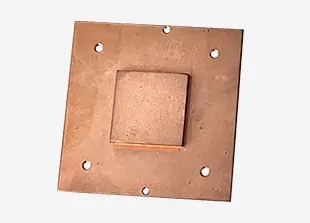

Copper CNC processing

About CNC processing of copper and copper alloy parts

In addition to the processing and production of aluminum parts, we also provide processing of copper and copper alloy CNC parts.

Copper and copper alloys have the advantages of electrical conductivity, thermal conductivity, and chemical stability. These advantages make copper and copper alloys widely used in electronics, construction, heat exchangers and other fields, and there is still a lot of potential and room for development in the future.

Why choose copper for parts?

1.Excellent physical properties

Copper is a good conductive material with high electrical and thermal conductivity. Compared with other metals, copper has a very small resistivity and still has good electrical conductivity at high temperatures, making it suitable for electrical equipment in high-temperature environments. In addition, copper has a moderate density, is not easily deformed, and is very wear-resistant, so copper products are not prone to problems under heavy load conditions.

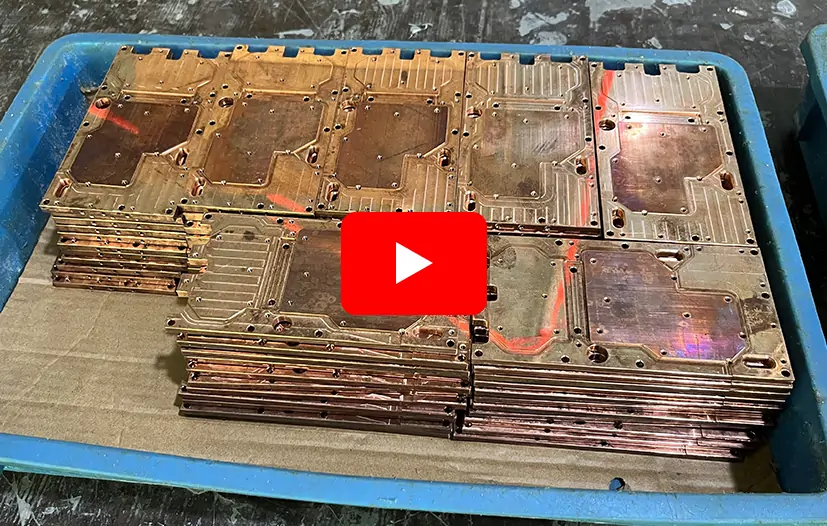

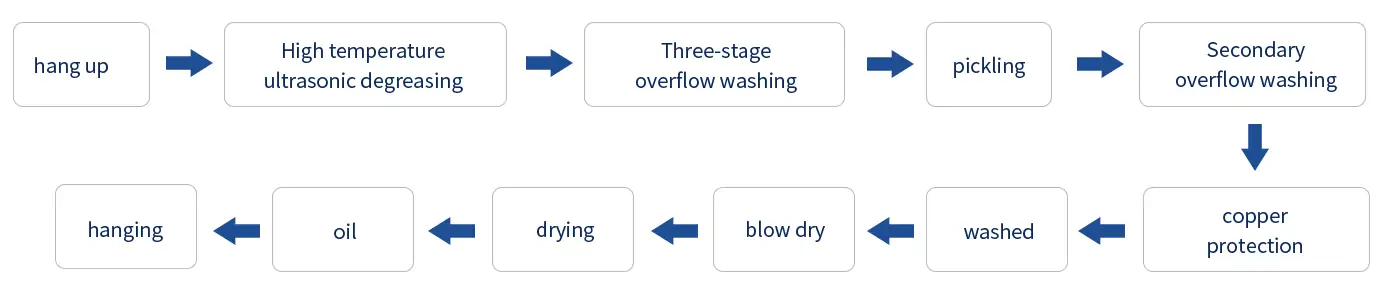

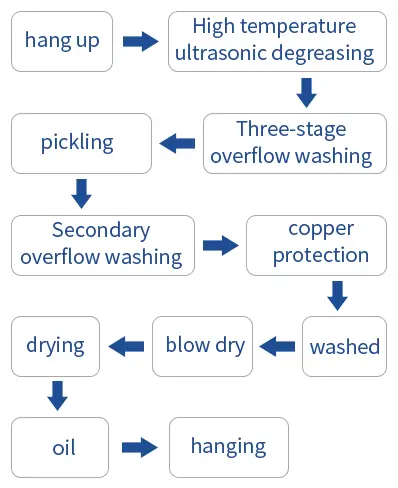

Copper parts cleaning process

Years of research and operation, we already have a mature process

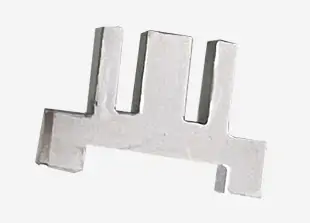

Below are some of the copper and copper alloy parts we produce

xuiron CNC processing

We provide a custom service

About a piece of customization, some small questions you want to know, we will answer you one by one

Can I order a sample first to check the quality?

We can provide a custom production service.

I will provide you with product drawings, and you can realize it, is that ok?

Yes. You provide drawings, we will produce according to your drawings. We have the ability to identify drawings and review drawings. Of course, if there is any ambiguity in the drawing, we will communicate with you by email or whatsapp;

How about the quality of a single product?

You don't have to worry about product quality. Regardless of the quantity of the processed products, we will take them seriously and ensure the quality.

How to pack and ship?

As for the packaging, we will pack it strictly to prevent the product from being damaged during transportation due to poor packaging. Regarding transportation, it depends on the size of the product. If the product is relatively small, you can choose air or express delivery; if the product is relatively large, you can only choose sea transportation.

Is it very expensive to customize a product?

The cost of making a single product will be higher than that of making a large batch of products. Because even if we make a product, our technical operators have to program the machine once. In addition, if we make a product separately, our cost of purchasing raw materials will be higher. Based on the above two factors, the cost of processing a product will increase.

What is the payment method for processing a product?

Since we only process one product, we usually ask the customer to pay 100%.

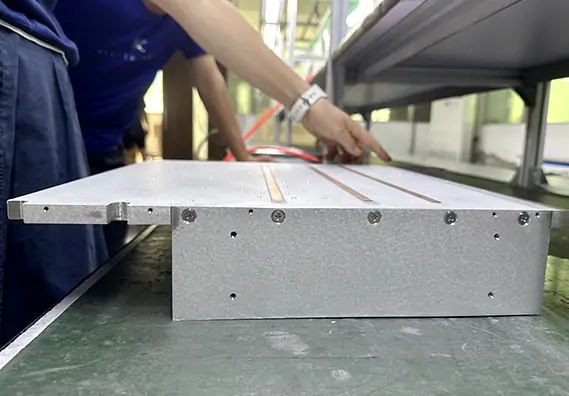

xuiron heat sink

Advantages of our workshop

Update device

We are constantly investing in equipment updates, improving efficiency and expanding the range of products we can manufacture.

Fast shipping

We have large and small parts processing machines and corresponding staff, and the processing speed is fast.

Good raw materials

Using high-quality copper and aluminum materials, strict product control.

Full mold

There are more than 2,000 existing molds, which can meet the needs of customers, and can also be tailored according to requirements.

customizable

There are a number of professional and technical engineers who can make molds and customize according to the requirements of the drawings.

well package

We enhance the durability of packaging, thereby reducing product damage during transportation.

xuiron heat sink

Industry application

Years of experience in the production of radiator systems and a sound quality management system have enabled us to produce more and more types of products, which are widely used in electric power, electronics, electrical appliances, LED lighting, automobiles, machinery and other industries.

medical instruments

Electronic equipment

Aerospace

Car manufacturer

metal manufacturing

Printing Industry

transportation industry

Chemical industry

xuiron heat sink

Why do you choose xuiron heat sink?

With many years of production experience, we already have a set of mature product production process. Each product must go through cleaning, polishing, anti-oxidation treatment and other procedures, and then be carefully packaged and transported before it can be sent out.

to clean

Rinse the finished radiator to remove dust and debris on the surface

Deburring

After each radiator is cut, it needs to be manually polished and deburred.

anti-oxidation

Put the parts into the protective solution for anti-oxidation treatment

Package

We use carton + wooden box double packaging to ensure the integrity of the product during transportation.

Contact

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right heat sink you want.

- Precision machining based on customer-provided drawings.

- Proficiency in machining pure aluminum and pure copper components.

- Ability to accommodate custom one-off machining requests.