Welcome to a deep dive into the world of cooling efficiency! In this article, we unveil the secret power of heatsink fins and how they play a crucial role in keeping your electronic devices cool.

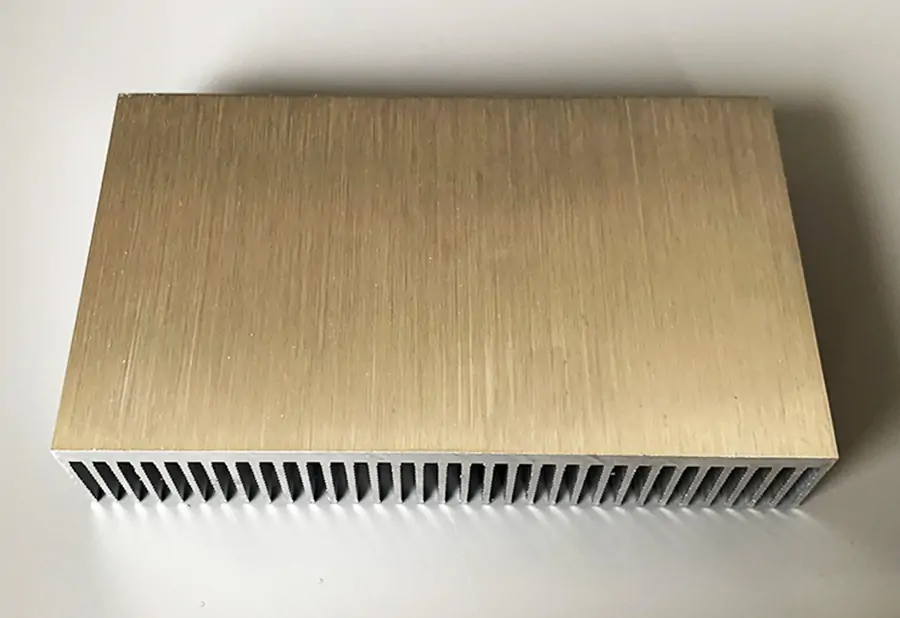

Heatsink fins are a fundamental component of the cooling system in many electronic devices, from computers to smartphones. These tiny but mighty fins are often overlooked, but they are actually the unsung heroes of heat dissipation. By maximizing surface area and increasing airflow, heatsink fins effectively dissipate heat generated by the device, ensuring optimal performance and longevity.

But how do heatsink fins achieve this remarkable feat? We'll explore the science behind their design and functionality, uncovering the principles that make them so efficient. Along the way, we'll discuss different types of heatsinks and their advantages, allowing you to make informed decisions when it comes to cooling solutions for your devices.

Whether you're a tech enthusiast or a curious reader, join us on this journey as we unleash the cooling power of heatsink fins and reveal the secrets that keep your devices running smoothly. Get ready to dive into a world where form meets function, and cooling efficiency is unleashed!

How heatsink fins improve cooling efficiency

Heatsink fins are a fundamental component of the cooling system in many electronic devices, from computers to smartphones. These tiny but mighty fins are often overlooked, but they are actually the unsung heroes of heat dissipation. By maximizing surface area and increasing airflow, heatsink fins effectively dissipate heat generated by the device, ensuring optimal performance and longevity.

To understand how heatsink fins improve cooling efficiency, we need to delve into the science behind their design and functionality. Heatsink fins are typically made of a thermally conductive material, such as aluminum or copper. These materials have excellent heat transfer properties, allowing them to efficiently absorb and distribute heat.

The key to the effectiveness of heatsink fins lies in their shape and arrangement. Fins are designed to have a large surface area relative to their volume, which enhances heat dissipation. Think of it like this: a flat plate would dissipate heat, but a plate with fins would dissipate heat much more efficiently due to the increased surface area. When heat is transferred to the fins, it is then conducted away and dissipated into the surrounding air.

The arrangement of the fins also plays a vital role in cooling efficiency. Fins are often closely spaced to maximize the number of fins within a given area, further increasing the surface area available for heat dissipation. This design allows for efficient heat transfer from the device to the fins and then to the surrounding air, preventing the device from overheating.

Heatsink fins also benefit from the principle of natural convection. As the heated air rises, fresh cool air is drawn in from the surroundings, creating a continuous airflow over the fins. This natural convection process enhances heat dissipation and keeps the device cool even during prolonged use or under heavy loads.

The science behind heatsink fins

To truly appreciate the power of heatsink fins, let's delve deeper into the science behind their design and functionality. As mentioned earlier, heatsink fins are made of thermally conductive materials, typically aluminum or copper. These materials have excellent heat transfer properties, allowing them to efficiently absorb and distribute heat.

The shape and arrangement of heatsink fins are carefully engineered to maximize cooling efficiency. Fins are often designed to have a high aspect ratio, which means they are taller and narrower. This shape increases the surface area available for heat dissipation without significantly increasing the overall size of the heatsink.

The size and spacing of the fins also play a crucial role in heat dissipation. Fins that are too small or too closely spaced can impede airflow, reducing cooling efficiency. On the other hand, fins that are too large or too widely spaced may not effectively dissipate heat. It's a delicate balance that requires careful consideration during the design process.

Additionally, the thickness of the fins affects their ability to conduct heat. Thicker fins can absorb and distribute heat more effectively, but they may also impede airflow. Thinner fins, on the other hand, allow for better airflow but may not conduct heat as efficiently. Designers must strike a balance between these factors to achieve optimal cooling performance.

Another important aspect of heatsink fin design is the baseplate. The baseplate is the part of the heatsink that makes direct contact with the heat-generating component. It serves as a bridge between the component and the fins, facilitating the transfer of heat. The baseplate should be made of a material with high thermal conductivity to ensure efficient heat transfer.

By understanding the science behind heatsink fins, we can appreciate their importance in maintaining the cooling efficiency of electronic devices. These seemingly simple components are the result of careful engineering and design, working in harmony to keep our devices running smoothly.

The Science Behind Heatsink Fins

Heatsink fins may appear simple, but their design is backed by scientific principles that make them highly efficient at dissipating heat. At the core of their functionality is the concept of maximizing surface area.

When a device generates heat, it needs a way to transfer that heat to the surrounding environment. This is where heatsink fins come into play. By increasing the surface area available for heat transfer, heatsink fins enable faster dissipation of heat.

The design of heatsink fins is often characterized by thin, elongated structures that resemble fins. These fins are usually arranged in a pattern, such as a grid or a honeycomb, to maximize the surface area even further. The greater the surface area, the more heat can be dissipated.

To enhance their heat dissipation capabilities, heatsink fins are often made from materials with high thermal conductivity, such as aluminum or copper. These materials efficiently conduct heat away from the device,allowing it to be released into the surrounding air.

Types of heatsink fins and their applications

Heatsink fins come in various shapes, sizes, and configurations, each tailored to specific cooling requirements.Let's explore some of the most common types of heatsink fins and their applications.

1. Straight Fin: The straight fin design is one of the simplest and most commonly used in heatsinks. These fins are straight and evenly spaced, providing a large surface area for heat dissipation. Straight fins are versatile and can be found in a wide range of electronic devices, from desktop computers to gaming consoles.

2. Pin Fin: Pin fins are cylindrical or conical in shape and resemble tiny pins protruding from the baseplate.These fins offer excellent heat dissipation capabilities due to their high aspect ratio. Pin fins are commonly used in compact devices, where space is limited but effective cooling is essential, such as laptops and small form factor PCs.

3. Staggered Fin: Staggered fins are arranged in a staggered pattern, with each fin positioned slightly offset from the adjacent ones. This design optimizes airflow and minimizes the risk of air blockage, resulting in enhanced cooling efficiency. Staggered fins are often found in high-performance devices that generate a significant amount of heat, such as graphics cards and power amplifiers.

4. Crosscut Fin: Crosscut fins feature a series of cuts or grooves along their length, increasing the surface area available for heat dissipation. These fins are particularly effective in dissipating heat from densely packed electronic components, such as memory modules and solid-state drives.

5. Folded Fin: Folded fins are characterized by their accordion-like shape, with multiple folds along their length.This design increases the surface area available for heat dissipation, allowing for efficient cooling in compact devices. Folded fins are commonly used in applications where space is limited, such as smartphones and tablets.

Each type of heatsink fin has its own advantages and applications, and choosing the right one for your device is crucial for optimal cooling performance. Factors such as heat dissipation requirements, available space, and airflow conditions should be taken into consideration when selecting heatsink fins.

Factors to consider when choosing heatsink fins

When it comes to choosing heatsink fins for your electronic devices, several factors should be taken into consideration to ensure optimal cooling performance. Let's explore these factors in detail.

1. Heat Dissipation Requirements: The first and most important factor to consider is the heat dissipation requirements of your device. Different electronic components generate varying amounts of heat, and the heatsink fins must be able to effectively dissipate that heat. Consider the maximum operating temperature of the component and choose heatsink fins that can handle the heat load.

2. Available Space: The size and form factor of your device will dictate the available space for heatsink fins. It's essential to choose fins that fit within the available space without obstructing other components or impeding airflow. Measure the dimensions of your device and select heatsink fins accordingly.

3. Airflow Conditions: The airflow conditions within your device play a crucial role in cooling efficiency. If your device has limited airflow or operates in a confined space, fins with a higher aspect ratio may be more suitable to enhance heat dissipation. On the other hand, devices with ample airflow can benefit from fins with wider spacing.

4. Material Selection: The choice of material for heatsink fins is another important consideration. Aluminum and copper are the most commonly used materials due to their excellent thermal conductivity. Aluminum is lightweight and cost-effective, making it a popular choice for consumer electronics. Copper, on the other hand,has superior heat transfer properties but is more expensive and heavier.

5. Manufacturing Process: The manufacturing process used to create heatsink fins can impact their performance and cost. Extruded fins, where the fins are formed by extruding a solid block of material, are commonly used in mass-produced heatsinks due to their cost-effectiveness. For higher-performance applications, fins made through processes like skiving or forging may be preferred.

By carefully considering these factors, you can choose heatsink fins that are best suited for your device's cooling needs. Optimal heat dissipation is crucial for maintaining the performance and longevity of electronic components, making the selection of heatsink fins a critical decision.

Installing and maintaining heatsink fins

Once you have selected the appropriate heatsink fins for your device, proper installation and maintenance are essential for optimal cooling performance. Follow these guidelines to ensure the effective operation of your heatsink fins:

1. Cleanliness: Before installing heatsink fins, ensure that the surface of the electronic component and the baseplate of the heatsink are clean and free from any dirt, dust, or thermal paste residue. Any impurities can hinder heat transfer and reduce cooling efficiency.

2. Thermal Interface Material: Apply a thin layer of high-quality thermal interface material, such as thermal paste or thermal pads, between the electronic component and the baseplate. This material helps to fill in microscopic gaps and ensures better heat transfer between the component and the heatsink.

3. Mounting Pressure: Ensure that the heatsink is securely mounted to the electronic component with the appropriate mounting pressure. Too little pressure can result in poor thermal contact, while excessive pressure can damage the component or distort the heatsink. Follow the manufacturer's guidelines for proper mounting pressure.

4. Airflow Optimization: Position your device in a way that allows for optimal airflow around the heatsink fins.Avoid obstructing vents or blocking the intake and exhaust areas of the device. You can also consider using additional fans or improving the overall airflow within the device to enhance cooling efficiency.

5. Regular Cleaning: Over time, heatsink fins can accumulate dust and debris, reducing their cooling effectiveness. Regularly clean the fins using compressed air or a soft brush to remove any buildup. Be gentle to avoid damaging the fins or dislodging them from the baseplate.

By following these installation and maintenance practices, you can ensure that your heatsink fins operate at their full potential, keeping your electronic devices cool and performing optimally.

Case studies: Real-world examples of improved cooling with heatsink fins

To showcase the effectiveness of heatsink fins in improving cooling efficiency, let's explore some real-world case studies where these tiny components made a significant difference.

1. Gaming Laptop: A gaming laptop was experiencing frequent overheating issues, leading to performance throttling and reduced gaming experience. By upgrading the heatsink with high-performance pin fins, the laptop's cooling system was able to dissipate heat more effectively, allowing for longer gaming sessions without overheating. The improved cooling performance resulted in enhanced overall performance and a smoother gaming experience.

2. Server Rack: A data center's server rack was struggling to maintain optimal operating temperatures, leading to frequent system shutdowns and reduced reliability. By replacing the existing heatsinks with staggered fins,the server rack's cooling system was able to handle the increased heat load more efficiently. The improved cooling performance resulted in reduced downtime and increased system stability.

3. High-Performance Desktop PC: A high-performance desktop PC, used for resource-intensive tasks like video editing and 3D rendering, was experiencing thermal throttling due to inadequate cooling. By upgrading the heatsink with crosscut fins, the PC's cooling system was able to dissipate heat more effectively, allowing for sustained high-performance operation without thermal limitations. The improved cooling performance resulted in faster rendering times and improved productivity.

These case studies demonstrate the significant impact that heatsink fins can have on cooling efficiency,ultimately leading to improved performance, reliability, and user experience. Whether it's a gaming laptop, a server rack, or a high-performance desktop PC, the right choice of heatsink fins can make all the difference in maintaining optimal operating temperatures.

DIY heatsink fin modifications for enhanced cooling

If you're a tech enthusiast looking to push the boundaries of cooling performance, you may consider making some DIY heatsink fin modifications. While it's important to note that modifying heatsink fins can void warranties and may require advanced technical skills, here are some ideas to explore:

1. Fin Spacing Optimization: By carefully adjusting the spacing between heatsink fins, you can optimize airflow and heat dissipation. Experiment with different spacing configurations to find the sweet spot that maximizes cooling efficiency. Keep in mind that too wide spacing can lead to reduced heat dissipation, while too narrow spacing can impede airflow.

2. Fin Thinning: Thinning the fins by carefully removing material can improve airflow and increase the surface area available for heat dissipation. This modification requires precision and care to avoid damaging the fins or compromising their structural integrity. Consider using specialized tools or seeking professional assistance for this modification.

3. Surface Finishing: The surface finish of heatsink fins can impact their ability to dissipate heat. Consider using thermal tape or thermal paint to enhance the thermal conductivity of the fins. These materials can fill in microscopic imperfections and improve heat transfer, resulting in improved cooling efficiency.

4. Fan Integration: If your device allows for it, you can integrate additional fans into the heatsink assembly to enhance airflow and cooling performance. This modification may require modifications to the device's casing and electrical connections, so it's important to proceed with caution and ensure proper compatibility and safety.

Remember, DIY heatsink fin modifications should be approached with caution and only undertaken if you have the necessary skills, knowledge, and understanding of the potential risks involved. Always prioritize safety and consult professional advice if needed.

Industry advancements and future trends in heatsink fin technology

The field of heatsink fin technology is constantly evolving, with advancements and innovations pushing the boundaries of cooling efficiency. Here are some notable industry advancements and future trends to keep an eye on:

1. Microfin Technology: Microfin heatsinks feature extremely small and densely packed fins, allowing for increased surface area and improved heat dissipation. This technology is particularly beneficial in applications where space is limited, such as mobile devices and wearable electronics. Expect to see more devices adopting microfin heatsinks for enhanced cooling performance.

2. Heat Pipe Integration: Heat pipes are hollow tubes filled with a heat transfer fluid that enables efficient heat transfer from the heat source to the fins. Integrating heat pipes into heatsink designs can significantly enhance cooling performance, especially in high-power applications. Look out for heatsinks that incorporate heat pipes for improved heat dissipation.

3. Additive Manufacturing: Additive manufacturing, also known as 3D printing, is revolutionizing the design and production of heatsink fins. This technology allows for complex geometries and customized designs,enabling heatsinks that are tailored to specific cooling requirements. Expect to see more innovative heatsink designs made possible by additive manufacturing.

4. Liquid Cooling Solutions: Liquid cooling solutions, such as liquid-cooled heatsinks, are gaining popularity in high-performance applications where air cooling alone may not be sufficient. Liquid-cooled heatsinks utilize a combination of liquid coolant and heatsink fins to dissipate heat effectively