Heatsinks play a crucial role in electronic devices by dissipating heat and preventing overheating. Without proper heat management, electronic components can malfunction or even fail, leading to costly repairs or replacements.

Customization Options in Heatsink Design

Customization options in heatsink design are essential for optimizing performance. By tailoring heatsinks to specific devices and applications, performance can be greatly enhanced.

Xuiron: A Leading Manufacturer of Customized Heatsinks

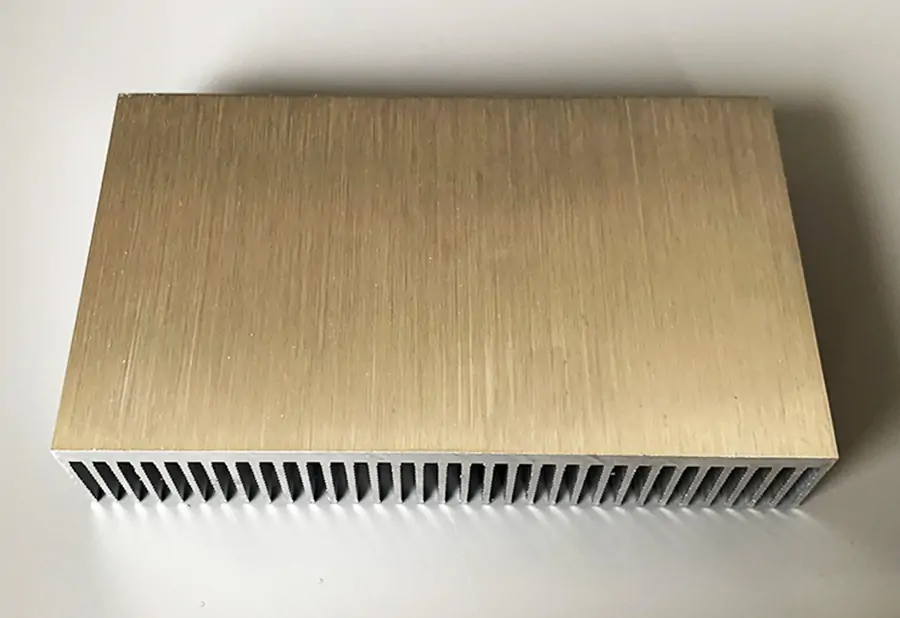

One company that specializes in customized heatsinks is Xuiron. Based in Hebei Province, China, Xuiron is a professional heatsink manufacturing company known for their expertise in producing customized extruded heatsinks and shovel tooth heatsinks. These heatsinks are designed to offer faster heat conduction and better heat dissipation.

High-Quality Materials for Efficient and Durable Heatsinks

Xuiron's heatsinks are made of high-quality materials such as pure aluminum or copper, ensuring efficiency and durability. They are widely used in various industries including network communications, medical care, artificial intelligence Internet of Things, automotive electronics, and semiconductor displays.

Strict Manufacturing Process for Customer Satisfaction

With a strict manufacturing process that includes cutting, tooth shoveling, hobbing, trimming, grinding, CNC processing, shaping, polishing, anti-oxidation treatment, and quality inspection, Xuiron prioritizes customer satisfaction and aims to deliver products according to specified delivery schedules.

Stay tuned to learn more about Xuiron's expertise in customized extruded heatsinks and shovel tooth heatsinks.

Advantages of Custom Heatsinks

Custom heatsinks offer several advantages over off-the-shelf options. One of the main benefits is that custom heatsinks can be tailored to specific application requirements, resulting in improved thermal management. Unlike generic heatsinks, which are designed to work with a wide range of components, custom heatsinks can be optimized to meet the unique thermal needs of a particular device or system.

When designing a custom heatsink, collaboration between the customer and the heatsink manufacturer is crucial. This collaboration ensures that the heatsink is designed to effectively dissipate heat and meet the customer's specific requirements. By working together, the customer can provide valuable insights into the device's thermal characteristics and operating conditions, while the manufacturer can leverage their expertise to design and manufacture a heatsink that is highly efficient and reliable.

Designing a Custom Heatsink

During the design process, the customer and manufacturer should consider various factors such as:

- The power dissipation of the device

- The available space for the heatsink

- Any specific cooling requirements

By taking these factors into account, a custom heatsink can be designed with the optimal size, shape, and fin density to maximize heat dissipation.

In addition to thermal performance, custom heatsinks can also be designed to meet other requirements such as weight, cost, and aesthetics. For example, if space is limited, a compact heatsink with a high surface area can be designed to ensure efficient heat transfer. If cost is a concern, the manufacturer can explore different materials and manufacturing techniques to find a cost-effective solution without compromising performance.

Overall, custom heatsinks offer significant advantages over off-the-shelf options. By tailoring the design to specific application requirements, custom heatsinks can provide improved thermal management and ensure the reliable operation of electronic devices. Collaboration between customers and heatsink manufacturers is essential to achieve optimal results during the design process. With the expertise and guidance of a professional heatsink manufacturer like Xuiron, customers can benefit from a custom heatsink solution that meets their unique needs and enhances the overall performance of their devices.

The Design Process of Custom Heatsinks

The design process is a crucial stage in the development of custom heatsinks. It involves several steps that aim to create an optimal heatsink design for specific heat dissipation requirements. Understanding these steps is essential for both customers and heatsink manufacturers to ensure effective customization and maximum performance.

Step 1: Needs Assessment

The first step in the design process is the needs assessment phase. This phase involves gathering information about the specific heat dissipation requirements of the application. It is important to understand factors such as the power density, ambient temperature, and thermal resistance of the system. By conducting a thorough needs assessment, manufacturers can tailor the heatsink design to meet the unique requirements of the application.

Step 2: Thermal Analysis

Once the needs assessment is complete, the next step is the thermal analysis process. This involves using specialized software and tools to analyze the thermal performance of the heatsink design. By simulating various scenarios, manufacturers can determine the optimal design parameters for efficient heat dissipation. This includes factors such as fin density, fin thickness, and base thickness. The thermal analysis process helps to ensure that the heatsink design will effectively dissipate heat and prevent overheating.

Step 3: Collaboration

Collaboration between customers and heatsink manufacturers is crucial throughout the design process. Effective communication and feedback from the customer allow manufacturers to understand any specific requirements or constraints. This collaboration ensures that the final heatsink design meets the customer's expectations and performs optimally in the intended application. Manufacturers can provide expertise and guidance to customers, helping them make informed decisions and achieve the desired results.

Step 4: Optimization

The final step in the design process is optimization. This phase involves refining the heatsink design to maximize its performance. Manufacturers may iterate on the design, making adjustments to improve thermal efficiency and reduce costs. Optimization can include factors such as adjusting the geometry, selecting different materials, or optimizing the manufacturing process. By continuously improving the design, manufacturers can deliver heatsinks that offer superior heat dissipation and meet the customer's specific requirements.

Custom Heatsink Manufacturing: Importance of Materials Selection

When it comes to custom heatsink manufacturing, the selection of materials plays a crucial role in ensuring optimal performance. The choice of materials directly impacts the heat conduction and dissipation capabilities of the heatsink. Xuiron, a professional heatsink manufacturing company, understands the importance of materials selection and utilizes high-quality materials to create efficient heatsinks.

Pure Aluminum and Copper: Excellent Thermal Conductivity

One of the advantages of using pure aluminum or copper for heatsink construction is their excellent thermal conductivity. Aluminum and copper are known for their high thermal conductivity properties, allowing them to quickly absorb and transfer heat away from the heat source. This efficient heat conduction helps to prevent overheating and maintain the overall performance of electronic devices .

Commitment to Quality Materials

Xuiron specifically focuses on using pure aluminum or copper for their heatsinks, ensuring that the materials are of the highest quality. By using pure materials, Xuiron guarantees the best possible heat conduction and dissipation for their heatsinks. This commitment to quality materials sets them apart from other manufacturers and ensures the reliability and performance of their products.

Advanced Manufacturing Techniques

In addition to materials selection, Xuiron employs various manufacturing techniques to create their heatsinks. These techniques include:

- Material cutting

- Tooth shoveling

- CNC processing

- Polishing

Each step of the manufacturing process is carefully executed to ensure precision and quality. The use of advanced manufacturing techniques allows Xuiron to create heatsinks that meet the specific requirements of their customers.

Strict Quality Assurance and Certification

To maintain the highest standards of quality, Xuiron follows strict quality assurance and certification processes. These processes ensure that each heatsink undergoes thorough testing and inspection to verify its reliability and performance. Xuiron's commitment to quality is evident in their attention to detail and their adherence to industry standards.

Delivering Efficient Heatsinks

Overall, Xuiron's materials selection and manufacturing processes are designed to deliver heatsinks that excel in heat conduction and dissipation. By using high-quality materials and employing advanced manufacturing techniques, Xuiron ensures that their heatsinks meet the demands of various industries, including:

- Network communications

- Medical care

- Artificial intelligence Internet of Things

- Automotive electronics

- Semiconductor displays

With their strict quality assurance and certification processes, Xuiron provides customers with heatsinks that they can rely on for efficient cooling and optimal performance.

Custom Heatsinks: Cost-Effective Solutions for Various Industries

Custom heatsinks offer cost-effective solutions for various industries, providing long-term benefits in terms of energy consumption and performance. By discussing the cost-effectiveness of custom heatsinks, highlighting the benefits of sample testing and optimization, and providing real-world examples, we can better understand how these solutions can benefit industries such as renewable energy storage systems, photovoltaic inverters, and data servers.

Cost-Effectiveness of Custom Heatsinks

When considering the cost-effectiveness of custom heatsinks in the long run, it is important to evaluate their overall performance and energy efficiency. Custom heatsinks are specifically designed to meet the unique requirements of different applications, ensuring optimal heat dissipation and reducing energy consumption. This results in significant cost savings over time, as the heat generated by electronic components is efficiently managed, reducing the need for additional cooling systems or expensive repairs.

Sample Testing and Optimization

Sample testing and optimization play a crucial role in achieving cost-effectiveness with custom heatsinks. By conducting sample testing, manufacturers can analyze the heat dissipation performance of their heatsinks and make necessary adjustments to optimize their design. This iterative process allows for continuous improvement, ensuring that the heatsinks meet the specific requirements of the application while minimizing energy consumption.

Real-World Examples

Real-world examples and case studies further illustrate the effectiveness of custom heatsinks in different industries:

- In the renewable energy storage systems industry, custom heatsinks are used to manage the heat generated by batteries, ensuring their longevity and reliability.

- In photovoltaic inverters, custom heatsinks are essential for maintaining the efficiency of the power conversion process, reducing energy losses and maximizing overall performance.

- In data servers, custom heatsinks play a crucial role in managing the heat generated by high-performance processors, ensuring stable operation and minimizing the risk of overheating.

These real-world examples demonstrate how custom heatsinks provide cost-effective solutions by reducing energy consumption and improving overall performance. By tailoring heatsink designs to the specific needs of different industries, companies can achieve optimal heat dissipation, resulting in energy savings and improved reliability. Custom heatsinks offer a long-term cost-effective solution for industries that rely on efficient thermal management.

Advantages of Custom Heatsinks

Custom heatsinks offer several advantages over off-the-shelf options:

- Tailored Design: With custom heatsinks, you can tailor the size, shape, and materials used to meet the specific needs of your application. This ensures optimal heat dissipation and better thermal management for your device.

- Energy Consumption Reduction: By designing a custom heatsink that effectively dissipates heat, you can prevent excessive heat buildup in your device. This leads to lower power consumption and increased energy efficiency, which is crucial in industries like automotive electronics and data centers.

- Certifications: When considering custom heatsinks, it is important to ensure that they meet the necessary certifications for safety and performance standards in your industry. Working with a reputable custom heatsink manufacturer can provide peace of mind and assurance that your device is operating within the required guidelines.

- Lead Time: The lead time for custom heatsink production can vary depending on complexity, quantity, and customization requirements. However, working with an experienced manufacturer can help streamline the production process and minimize lead times.

- Long-Term Cost Savings: While there may be a higher upfront cost associated with custom heatsinks, they can prove to be cost-effective in the long run. By optimizing the heatsink design for your specific application, you can prevent potential issues such as overheating, component failures, and costly repairs.

In conclusion, custom heatsinks provide numerous benefits over off-the-shelf options. They offer the flexibility to design a heatsink that precisely fits your application, leading to improved thermal management and device performance. Custom heatsinks can also contribute to energy consumption reduction and help meet industry certifications. While there may be a higher upfront cost, they can prove cost-effective in the long run by preventing potential issues and maximizing the lifespan of your device. Working with a reputable custom heatsink manufacturer like Xuiron can ensure the successful implementation of your custom heatsink solution.

Customization is Key

When it comes to heatsinks, customization is key, and Xuiron understands this better than anyone. As a professional heatsink manufacturing company based in Hebei Province, China, Xuiron specializes in the production of customized extruded heatsinks and shovel tooth heatsinks.

Xuiron knows that every application has unique requirements, and their commitment to delivering tailored solutions is what sets them apart. Their heatsinks offer faster heat conduction and better heat dissipation, thanks to their use of pure aluminum or copper. These high-quality materials make Xuiron's heatsinks ideal for industries such as:

- Network communications

- Medical care

- Artificial intelligence Internet of Things

- Automotive electronics

- Semiconductor displays

But it's not just about the materials. Xuiron follows a strict manufacturing process that includes cutting, shoveling, hobbing, trimming, grinding, CNC processing, shaping, polishing, anti-oxidation treatment, and quality inspection. This attention to detail ensures that every heatsink meets the highest standards.

Customer Satisfaction is a Priority

What truly sets Xuiron apart is their focus on customer satisfaction. They aim to deliver products according to the specified delivery schedule, and their efficient manufacturing processes, strict quality inspection, enhanced packaging, and continuous equipment updates ensure that customers receive the best possible heatsinks.

Xuiron also offers customization options and supports various shipping methods, making it easy for customers to get the heatsinks they need. Whether you're looking for more information, a quote, or precision machining based on your provided drawings, Xuiron's website is the place to go.

Choose Customized Solutions

As the saying goes, "One size does not fit all," and this holds true for heatsinks as well. Xuiron's commitment to customization ensures that every heatsink is perfectly tailored to meet the unique needs of each application.

If you're in need of high-quality heatsinks that provide superior heat conduction and dissipation, visit Xuiron's website today. Get in touch with their team for more information, request a quote, or submit your precision machining drawings. Don't settle for generic heatsinks – choose Xuiron for customized solutions that deliver optimal performance.