Importance of Heat Sinks in Electronic Devices

Heat sinks play a crucial role in maintaining the optimal performance of electronic devices by efficiently managing thermal energy.

Role of Heat Sinks in Improving Device Performance

By effectively dissipating heat, heat sinks prevent overheating, ensure stability, and prolong the lifespan of electronic components.

Brief Introduction to Xuiron and Its Specialization in Heat Sink Manufacturing

Xuiron, a professional heatsink manufacturing company, focuses on producing high-quality heat sinks made of pure aluminum or copper for various industries, ensuring effective heat management and improved electronic device performance.

What are Heat Sinks?

Heat sinks are essential components designed to efficiently dissipate heat from electronic devices, safeguarding them from overheating and maintaining optimal performance. These components play a critical role in various industries that rely on electronic devices, ranging from network communications and medical care to artificial intelligence, automotive electronics, and semiconductor displays.

Definition and function of heat sinks

Heat sinks are typically made of materials with high thermal conductivity, such as copper or aluminum, which facilitate the rapid transfer of heat away from the device. By absorbing and dispersing the heat, these components help to maintain a stable temperature within the device, prolonging its lifespan and ensuring consistent performance.

Applications of heat sinks in various industries

Heat sinks are commonly found in electronic devices across numerous industries. Some of these industries include: Network communications: In this industry, heat sinks are vital for preventing overheating in devices such as routers, switches, and servers, ensuring seamless data transmission and communication. Medical care: Heat sinks are used to regulate the temperature of medical equipment, such as MRI machines and diagnostic devices, ensuring accurate results and proper functioning. Artificial intelligence and Internet of Things: As AI and IoT devices continue to evolve, the need for effective heat management becomes even more critical. Heat sinks help to maintain optimal temperatures in these devices, allowing for efficient processing and performance. Automotive electronics: In the automotive industry, heat sinks are used to dissipate heat from electronic control units, sensors, and other components, ensuring the safety and performance of vehicles. Semiconductor displays: Heat sinks play a crucial role in regulating the temperature of display components such as LEDs and OLEDs, helping to prevent damage and prolong the lifespan of these devices. In summary, heat sinks are indispensable components in the world of electronics, providing effective heat management solutions for a wide range of devices and industries.

How Heat Sinks Work

In order to understand how heat sinks contribute to the improved performance of electronic devices, it is essential to examine the processes involved in their operation. Heat sinks work through two primary mechanisms: heat conduction and heat dissipation.

Heat Conduction Process

Heat conduction is the transfer of thermal energy from a high-temperature region to a lower-temperature region within a material or between different materials in contact. In the context of electronic devices, heat is generated by various components such as processors, memory modules, and power supplies. The heat sink, usually made of materials with high thermal conductivity like aluminum or copper, is placed in direct contact with the heat-generating components. The heat is then conducted from these components into the heat sink material, which serves as a medium for heat transfer.

Heat Dissipation Mechanisms

Once the heat has been conducted into the heat sink, it must be efficiently dissipated into the surrounding environment to prevent the electronic components from overheating and to maintain their optimal performance. There are two primary mechanisms through which heat sinks dissipate heat: Convection: Heat transfer between the heat sink and the surrounding air occurs through convection. As the air comes into contact with the heat sink's surface, it absorbs the heat and moves away, allowing cooler air to replace it and continue the heat transfer process. Passive heat sinks rely solely on natural convection, while active heat sinks employ fans or other cooling devices to facilitate forced convection and increase the rate of heat dissipation. Radiation: Heat sinks also dissipate heat through radiation, which is the transfer of heat in the form of electromagnetic waves. All objects emit thermal radiation, and the heat sink's surface temperature determines the rate at which it radiates heat. Radiation is generally a less significant contributor to heat dissipation compared to convection but still plays a role in the overall heat sink performance. In summary, heat sinks improve the performance of electronic devices by efficiently conducting heat away from heat-generating components and dissipating it into the surrounding environment through convection and radiation processes. The choice of heat sink materials, design, and type plays a crucial role in determining the effectiveness of these heat transfer mechanisms and ultimately the performance of the electronic devices they serve to protect.

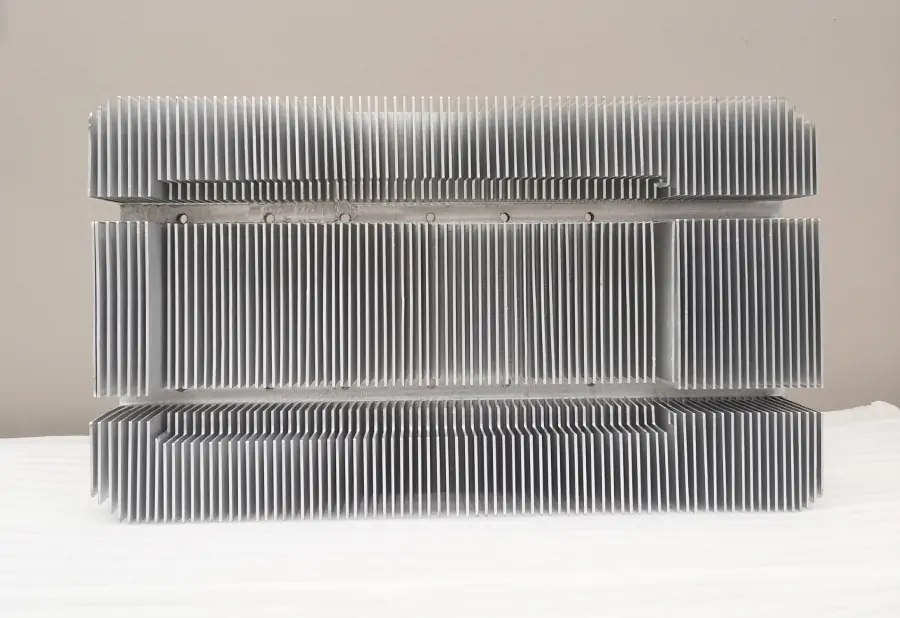

Types of Heat Sinks

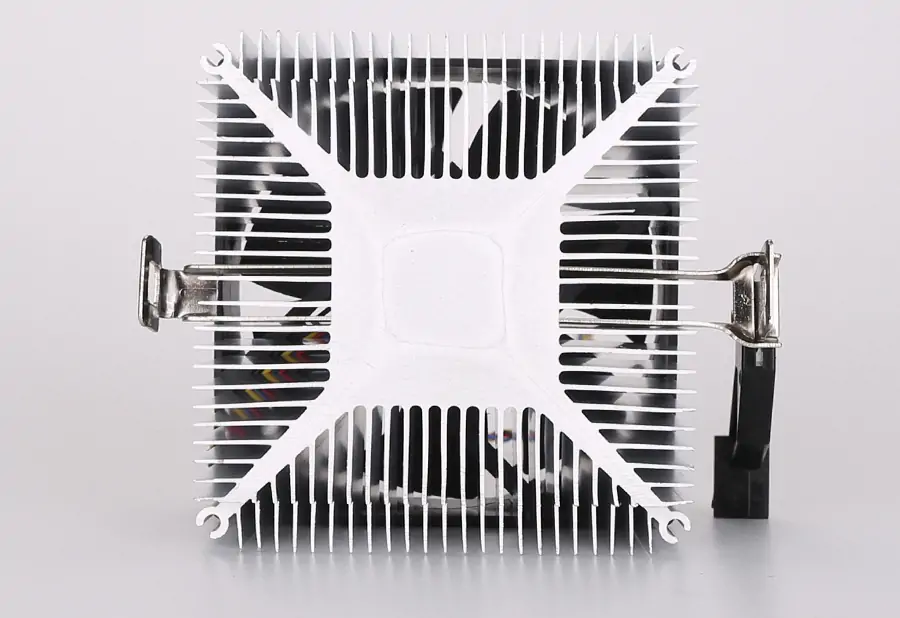

Heat sinks play a crucial role in managing the heat generated by electronic devices, and their efficiency depends on various factors, such as type, material, and design. There are several types of heat sinks, each with its unique characteristics and applications. Let's explore some common types of heat sinks: Active Heat Sinks Active heat sinks are designed to incorporate a fan or other cooling mechanism that actively dissipates heat from the device. By using the forced air provided by the fan, active heat sinks can enhance the cooling performance, making them suitable for high-power electronic devices that generate a significant amount of heat. However, active heat sinks may require additional power and maintenance due to the presence of moving parts.

Passive Heat Sinks

Passive heat sinks, on the other hand, rely solely on the process of natural convection to dissipate heat. These heat sinks do not include any moving parts or additional cooling mechanisms, making them energy-efficient and low maintenance. Passive heat sinks are generally constructed from materials with high thermal conductivity, such as aluminum or copper. They are suitable for electronic devices with lower power requirements and heat generation.

Pin-Fin Heat Sinks

Pin-fin heat sinks are a type of passive heat sink characterized by the presence of pins or rods extending from the base of the heat sink. The pins increase the surface area available for heat dissipation, promoting efficient cooling. Pin-fin heat sinks can be manufactured using various materials, including aluminum and copper. They are versatile and can be used in both horizontal and vertical orientations, making them suitable for a wide range of electronic devices.

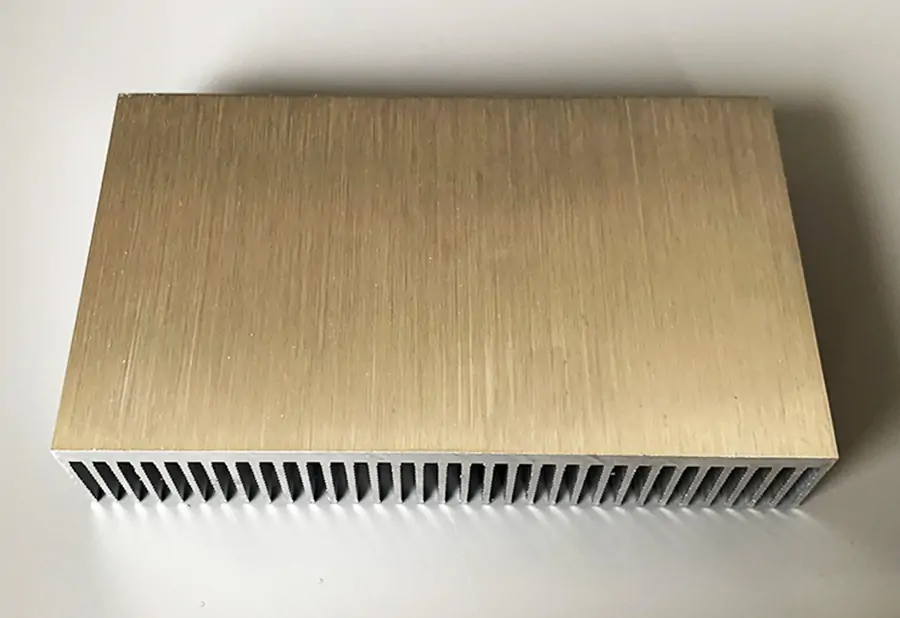

Plate-Fin Heat Sinks

Plate-fin heat sinks are another type of passive heat sink that consists of flat plates or fins extending from the base. These fins increase the surface area available for heat transfer, enhancing the cooling performance. Plate-fin heat sinks are typically made of materials with high thermal conductivity, such as aluminum or copper. They are commonly used in electronic devices where space constraints do not allow for the use of pin-fin heat sinks. In conclusion, the choice of heat sink type depends on the specific requirements of the electronic device, including the amount of heat generated, space constraints, and power requirements. By understanding the different types of heat sinks and their characteristics, it is possible to make informed decisions that lead to improved performance and longevity of electronic devices.

Heat Sink Materials

Heat sinks are typically made from two primary materials: copper and aluminum. Each material offers unique benefits and drawbacks when used in heat sink construction. In this section, we will explore the properties of these materials and the advantages of Xuiron's pure aluminum or copper heat sinks. Copper Copper is a highly conductive material, making it an excellent choice for heat sinks. Its high thermal conductivity allows for faster heat transfer, which helps in efficiently dissipating heat from electronic components. However, copper is denser and more expensive than aluminum, which can be a disadvantage when it comes to manufacturing costs and weight considerations in some applications. Aluminum Aluminum is another popular material used in heat sink manufacturing due to its lower cost and lighter weight compared to copper. While it has a lower thermal conductivity than copper, it still performs effectively in dissipating heat from electronic devices. Aluminum heat sinks are particularly suitable for applications where weight and cost are critical factors. Advantages of Xuiron's Pure

Xuiron specializes in manufacturing heat sinks made from pure aluminum or copper, ensuring high-quality and efficient heat dissipation. By using pure materials, Xuiron's heat sinks offer superior thermal conductivity, which translates into improved performance of electronic devices. Additionally, Xuiron's strict manufacturing processes and quality inspection procedures guarantee that their heat sinks meet the highest standards of quality and performance, making them an ideal choice for industries such as network communications, medical care, artificial intelligence and Internet of Things, automotive electronics, and semiconductor displays.

Heat Sink Manufacturing Process at Xuiron

At Xuiron, the manufacturing process of heat sinks follows a strict and comprehensive procedure to ensure the production of high-quality and efficient heat sinks. The process consists of various steps that are crucial for achieving top-notch heat dissipation performance. The stages in the manufacturing process include:

Material cutting: The process begins with cutting the selected heat sink material, such as copper or aluminum, into the required dimensions.

Tooth shoveling: This step involves removing material from the heat sink to create the desired fin structure for efficient heat dissipation.

Hobbing: A hobbing machine is used to create the intricate fin patterns on the heat sink, which are crucial for maximizing surface area and optimizing heat transfer.

Trimming: Excess material is trimmed away to ensure the heat sink meets the desired specifications and dimensions.

Grinding: The heat sink undergoes a grinding process to smooth out any rough edges and improve its overall appearance and performance.

CNC processing: Computer Numerical Control (CNC) machines are employed to further refine the heat sink's shape and design, ensuring precise and accurate dimensions.

Shaping: The heat sink is shaped according to the specific design requirements of the electronic device it will be used in.

Polishing: The heat sink's surface is polished to enhance its thermal conductivity and ensure efficient heat transfer.

Anti-oxidation treatment: A protective coating is applied to the heat sink to prevent oxidation and corrosion, thus prolonging its lifespan and maintaining its performance.

Quality inspection: Finally, each heat sink undergoes a thorough quality inspection to ensure it meets the high standards set by Xuiron and performs efficiently in its intended application.

In conclusion, Xuiron's strict and comprehensive heat sink manufacturing process is a testament to their commitment to producing high-quality products that effectively improve the performance of electronic devices through efficient heat dissipation.

Comparisons between Heat Sinks and Other Heat Dissipation Devices

In this section, we will explore various heat dissipation devices and how they differ from heat sinks. These devices play a crucial role in maintaining the optimal performance of electronic components by preventing overheating. As a result, it is essential to understand their specific applications and effectiveness in comparison to heat sinks.

Plate Heat Exchangers

Plate heat exchangers consist of a series of thin, corrugated metal plates that are stacked together to facilitate heat transfer between two fluids. The fluids flow in opposite directions, allowing for efficient heat exchange. While plate heat exchangers can be highly effective in some applications, they are not commonly used in electronics cooling due to their size, complexity, and the need for a liquid coolant. In contrast, heat sinks provide a simpler, more compact solution for electronics cooling.

Cooling Radiators

Cooling radiators are designed to dissipate heat by transferring it to the surrounding air. They are typically used in conjunction with fans and liquid cooling systems to enhance heat transfer efficiency. Although cooling radiators can be effective in some scenarios, they may not be suitable for all electronic devices due to their reliance on additional components and potential for increased noise levels. Heat sinks, on the other hand, offer a more versatile and noise-free alternative.

Thermal Paste

Thermal paste is a thermally conductive compound that is applied between a heat sink and a heat-generating component to improve heat transfer. While it is essential for ensuring optimal heat sink performance, thermal paste alone is not enough to provide adequate cooling. Heat sinks are still required to dissipate the heat effectively.

Thermal Conductive Sheets

Thermal conductive sheets are thin, flexible materials with high thermal conductivity. They are often used to fill gaps between heat-generating components and heat sinks or other cooling solutions. While they can improve heat transfer, they do not replace the need for heat sinks. Instead, they complement heat sinks to enhance their overall effectiveness.

Vapor Chambers

Vapor chambers are advanced cooling solutions that utilize the phase change of a working fluid to dissipate heat. They offer high thermal conductivity and can spread heat uniformly across a large surface area. However, vapor chambers are generally more expensive and complex than heat sinks, making them less suitable for a wide range of electronic devices. Heat sinks remain a more cost-effective and straightforward solution for many applications.

Why Choose Xuiron Heat Sinks

When selecting heat sinks for your electronic devices, it is crucial to choose a company that is dedicated to providing high-quality products and excellent customer service. Xuiron is the ideal choice for heat sink manufacturing for several reasons:

Efficient Manufacturing Processes

Xuiron follows a strict manufacturing process that includes material cutting, tooth shoveling, hobbing, trimming, grinding, CNC processing, shaping, polishing, anti-oxidation treatment, and quality inspection. This ensures the production of heat sinks that meet high standards of quality and performance.

Strict Quality Inspection

Quality is a top priority for Xuiron. They have a rigorous quality inspection process in place to ensure that their heat sinks meet the highest standards and customer expectations.

Enhanced Packaging

Xuiron goes the extra mile to protect their products during shipping by using thickened cartons and wooden boxes for packaging. This ensures that your heat sinks arrive in perfect condition, ready for installation.

Continuous Equipment Updates

Staying up-to-date with the latest technology is vital in the heat sink manufacturing industry. Xuiron continuously updates its equipment to provide customers with the most advanced and efficient heat sinks on the market.

Customization Options

Every project has unique requirements, and Xuiron understands this. They offer customization options for their heat sinks to ensure that customers receive the perfect solution for their specific needs.

Customer Satisfaction

At the core of Xuiron's mission is a commitment to customer satisfaction. They strive to deliver products according to the specified delivery schedule and have received high praise from customers in the industry for their excellent customer service. In conclusion, Xuiron is an ideal choice for heat sink manufacturing, offering efficient processes, high-quality products, and a dedication to customer satisfaction. With their expertise in heat sink manufacturing, you can trust Xuiron to provide effective heat management solutions for your electronic devices.

How to Contact Xuiron

If you are interested in Xuiron's high-quality heat sinks and want to learn more about their products or request a quote, contacting them is easy and convenient. To get started, visit their website at https://xuiron.com , where you can find detailed information about their heat sink offerings and manufacturing processes. Requesting a quote from Xuiron is a straightforward process. Simply fill out the contact form available on their website with your requirements, and their team will get back to you with a detailed quote that suits your needs. Xuiron is committed to providing excellent customer service and ensuring that all inquiries are addressed promptly and professionally. When it comes to shipping options and payment methods, Xuiron offers a variety of choices for customers. They use thickened cartons and wooden boxes for packaging, ensuring that the heat sinks are protected during transportation. Shipping methods can be customized according to the customer's preferences, and the supported payment method is TT (Telegraphic Transfer). This flexibility allows customers to choose the options that work best for them. As for production lead time, it depends on the order quantity and specific products. Xuiron is dedicated to delivering products according to the specified delivery schedule, ensuring that customers receive their heat sinks on time and can proceed with their projects without any delays. In conclusion, contacting Xuiron is a hassle-free experience, and their team is always ready to assist you with any inquiries or concerns you may have. Their commitment to customer satisfaction and providing top-notch heat sinks make Xuiron a reliable choice for your electronic device's thermal management needs.

Enhance Performance with Xuiron

Heat sinks play a crucial role in improving electronic device performance by efficiently dissipating heat. Xuiron, with its expertise in heatsink manufacturing, offers high-quality heat sinks that ensure effective heat management and customer satisfaction. Their products, made of pure aluminum or copper, cater to various industries such as network communications, medical care, artificial intelligence, Internet of Things, automotive electronics, and semiconductor displays. They focus on customer satisfaction and deliver products according to the specified delivery schedule. To explore Xuiron's heat sink offerings and request a quote, visit their website .