Pin fin heat sinks play a crucial role in maintaining the performance and longevity of electronic devices by effectively dissipating heat. As electronic devices continue to evolve and become more compact, efficient heat dissipation becomes increasingly important. This is where pin fin heat sinks excel, maximizing heat dissipation and ensuring optimal operation of various electronic components.

Understanding Pin Fin Heat Sinks

Pin fin heat sinks are designed to provide an efficient solution for maximizing heat dissipation in various electronic devices. They have a unique structure and function, setting them apart from other types of heat sinks. In this section, we will explore the design and structure of pin fin heat sinks, how they work in dissipating heat, and compare them with other heat sink types.

Design and Structure of Pin Fin Heat Sinks

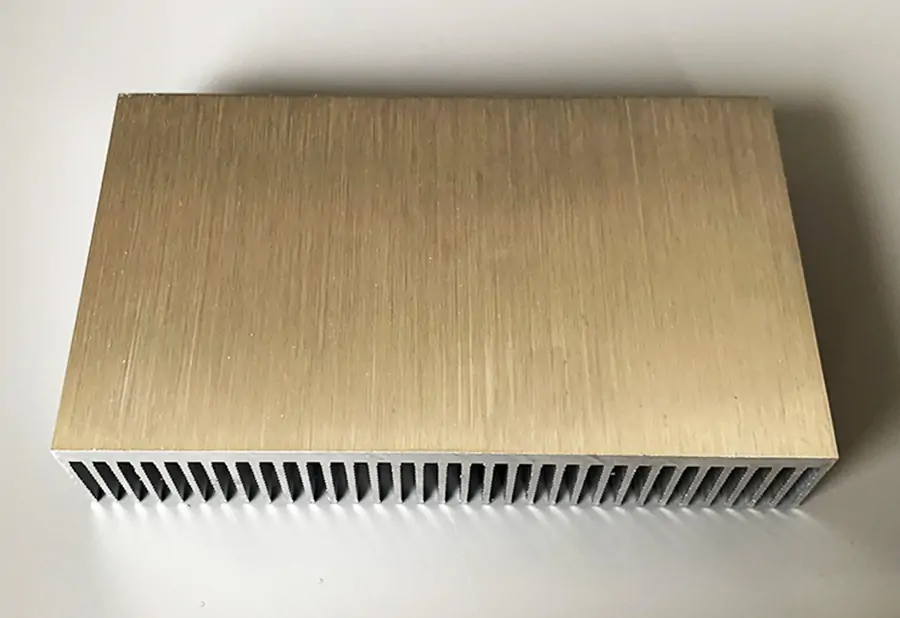

Pin fin heat sinks feature numerous thin, elongated pins that extend from the base of the heat sink. These pins can be arranged in various configurations, such as straight or staggered, to optimize heat dissipation. The primary purpose of the pins is to increase the surface area of the heat sink, allowing for more efficient heat transfer between the heat sink and the surrounding air. The pins are usually made of materials with high thermal conductivity, such as aluminum or copper, to ensure effective heat dissipation.

How Pin Fin Heat Sinks Work in Dissipating Heat

Heat dissipation in pin fin heat sinks occurs through a combination of conduction, convection, and radiation. First, the heat generated by the electronic device is transferred to the base of the heat sink through conduction. This heat is then distributed to the pins, which extend outward and serve as pathways for heat transfer. The increased surface area provided by the pins allows for better contact with the surrounding air, enhancing heat dissipation through convection. Additionally, some heat is released through radiation, further contributing to the cooling process.

Comparison of Pin Fin Heat Sinks with Other Types of Heat Sinks

Compared to other types of heat sinks, such as extruded or folded fin heat sinks, pin fin heat sinks offer several advantages. The increased surface area provided by the pins allows for more efficient heat dissipation, making pin fin heat sinks suitable for applications with high heat loads and compact spaces. Furthermore, their design enables them to perform well in various orientations, ensuring optimal thermal performance regardless of the device's position. In summary, pin fin heat sinks are an effective solution for maximizing heat dissipation in electronic devices due to their unique design and structure. By utilizing pins to increase the surface area and optimize heat transfer, these heat sinks offer improved thermal performance compared to other heat sink types, making them ideal for a variety of applications.

Advantages of Pin Fin Heat Sinks

Pin fin heat sinks offer several advantages that make them an ideal choice for efficient thermal management in various applications. These benefits stem from their unique design, which allows for enhanced heat dissipation, better thermal performance in different orientations, and efficient cooling in compact spaces.

Enhanced Heat Dissipation Due to Increased Surface Area

One of the primary advantages of pin fin heat sinks is their ability to provide enhanced heat dissipation compared to other types of heat sinks. The increased surface area resulting from the pin-like protrusions on the heat sink allows for more efficient heat transfer from the heat source to the surrounding air. This design also ensures that heat is spread evenly across the heat sink, which helps prevent hotspots and improve the overall thermal performance of the device.

Better Thermal Performance in Various Orientations

Pin fin heat sinks also excel at providing better thermal performance in different orientations. Unlike some other heat sink designs that rely on a specific orientation for optimal heat dissipation, pin fin heat sinks can effectively dissipate heat in any orientation. This flexibility makes them suitable for a wide range of applications and mounting configurations, ensuring consistent and reliable cooling performance regardless of the device's orientation.

Efficient Cooling in Compact Spaces

Another advantage of pin fin heat sinks is their ability to provide efficient cooling in compact spaces. The pin-like protrusions enable them to efficiently dissipate heat even in tight spaces where other heat sink designs may struggle. This makes pin fin heat sinks a popular choice for cooling high-performance electronic devices that have limited space for heat sink installation, such as network communications equipment, automotive electronics, and artificial intelligence Internet of Things devices.Another advantage of pin fin heat sinks is their ability to provide efficient cooling in compact spaces. The pin-like protrusions enable them to efficiently dissipate heat even in tight spaces where other heat sink designs may struggle. This makes pin fin heat sinks a popular choice for cooling high-performance electronic devices that have limited space for heat sink installation, such as network communications equipment, automotive electronics, and artificial intelligence Internet of Things devices.

Applications of Pin Fin Heat Sinks

Pin fin heat sinks are highly versatile and adaptable, making them a popular choice for various applications across different industries. By understanding how these heat sinks can benefit different sectors, it becomes easier to appreciate their importance and relevance in today's world. Electronic Devices Pin fin heat sinks are widely used in electronic devices such as computers, laptops, and gaming consoles, where they effectively dissipate heat generated by high-performance processors and other components. By providing efficient cooling, these heat sinks help maintain optimal operating temperatures, thereby ensuring the longevity and performance of these devices.

LED Lighting

LED lighting is known for its energy efficiency and long lifespan. However, it still generates heat that needs to be managed. Pin fin heat sinks are ideal for LED lighting systems, as they can efficiently dissipate the heat generated by the LED chips, preventing premature failure and maintaining consistent light output and color quality.

Automotive Electronics

Modern vehicles rely heavily on electronics for various functions such as engine management, safety systems, and infotainment. Pin fin heat sinks can be found in automotive electronics, where they help manage the heat generated by power-hungry components, ensuring the reliability and performance of these systems.

Power Electronics

Power electronics, such as converters, inverters, and power supplies, generate significant amounts of heat during operation. Pin fin heat sinks are an excellent solution for managing this heat, as they provide enhanced thermal performance, allowing power electronics to function efficiently and safely.

Renewable Energy Systems

Renewable energy systems, such as solar inverters and wind turbine generators, require effective thermal management to ensure efficient operation and long service life. Pin fin heat sinks can be employed in these systems to dissipate the heat generated by electronic components, contributing to the overall efficiency and reliability of renewable energy solutions.

Industrial Machinery

Industrial machinery, including robots, CNC machines, and manufacturing equipment, often incorporate pin fin heat sinks to manage the heat generated by high-powered motors and other components. By providing efficient cooling, these heat sinks contribute to the smooth operation and maintenance of industrial machinery. Network Communications, Medical Care, and Artificial Intelligence Internet of Things Pin fin heat sinks are also utilized in network communications equipment, medical devices, and artificial intelligence Internet of Things (AIoT) applications, where they help maintain stable operating temperatures, ensuring optimal performance and reliability of these crucial technologies.

Xuiron's Pin Fin Heat Sink Offerings

Xuiron is a professional heatsink manufacturing company based in Hebei Province, China, specializing in the production of customized extruded heatsinks and shovel tooth heatsinks. Their products, including pin fin heat sinks, are designed to ensure faster heat conduction and better heat dissipation. One of the key features of Xuiron's pin fin heat sinks is their ability to be customized according to the specific needs of various applications and industries. This flexibility allows them to cater to a wide range of customers, ensuring that their products meet the specific requirements of each application. In addition to offering customization options, Xuiron follows a strict manufacturing process that includes material cutting, tooth shoveling, hobbing, trimming, grinding, CNC processing, shaping, polishing, anti-oxidation treatment, and quality inspection. This rigorous process ensures that their pin fin heat sinks provide optimal performance and reliability. Moreover, Xuiron's pin fin heat sinks are widely used in industries such as network communications, medical care, artificial intelligence Internet of Things, automotive electronics, and semiconductor displays. This showcases the versatility and effectiveness of their products in a variety of applications and environments.

Tips for Maximizing Heat Dissipation with Pin Fin Heat Sinks

Maximizing heat dissipation with pin fin heat sinks is crucial for maintaining the optimal performance of electronic devices. In this section, we will explore four essential tips to achieve the best thermal management possible using pin fin heat sinks.

A. Proper selection of materials for heat sinks

The material used for the heat sink plays a vital role in its efficiency. Commonly used materials include aluminum and copper, each with their unique properties. Aluminum is lightweight and cost-effective, making it a popular choice for many applications. Copper, on the other hand, has better thermal conductivity, but it is heavier and more expensive. Therefore, the choice of material should be based on the specific requirements of your application and the trade-offs you are willing to make.

B. Ensuring adequate airflow and cooling mechanisms

Effective heat dissipation requires proper airflow and cooling mechanisms in place. This can be achieved by ensuring that there is adequate space around the heat sink for air to flow and dissipate heat. Additionally, using cooling mechanisms like fans or liquid cooling systems can further enhance the performance of the pin fin heat sink. The choice of cooling method depends on the application and the thermal requirements of the device.

C. Customization for specific applications and devices

Customizing pin fin heat sinks for specific applications and devices can greatly improve their performance. This may involve adjusting the size, shape, or arrangement of the fins to maximize the surface area for heat dissipation. Working with a professional heatsink manufacturing company like Xuiron ensures that your customized heat sink will meet the specific requirements of your application.

D. Regular maintenance and cleaning to maintain optimal performance

Regular maintenance and cleaning of the pin fin heat sink are essential for maintaining its optimal performance. Dust and debris can accumulate on the fins over time, reducing their effectiveness in dissipating heat. Therefore, it is crucial to clean the heat sink periodically, using compressed air or a soft brush to remove any accumulated dust. This will help maintain the heat sink's performance and prolong the life of your electronic devices.

Conclusion

In conclusion, pin fin heat sinks play a crucial role in the thermal management of electronic devices, providing significant benefits over other types of heat sinks. By offering enhanced heat dissipation due to their increased surface area, better thermal performance in various orientations, and efficient cooling in compact spaces, pin fin heat sinks can effectively maximize heat dissipation. Moreover, pin fin heat sinks find extensive applications in various industries, such as electronic devices, LED lighting, automotive electronics, power electronics, renewable energy systems, and industrial machinery, among others. As a professional heatsink manufacturing company, Xuiron specializes in producing customized pin fin heat sinks, ensuring faster heat conduction and better heat dissipation. Their strict manufacturing process, attention to quality, and customer-focused approach make them an ideal partner for your pin fin heat sink requirements. Therefore, we encourage you to explore Xuiron's offerings and consider their customized pin fin heat sinks to optimize the thermal performance of your devices and applications. With Xuiron's expertise and commitment to excellence, you can trust that their pin fin heat sinks will contribute significantly to maximizing heat dissipation in your applications.

Discover Xuiron's Solutions

Having explored the advantages and applications of pin fin heat sinks, it's time to take the next step in maximizing heat dissipation for your devices. Dive deeper into the world of heatsink manufacturing with Xuiron: Learn More : Visit Xuiron's blog for insightful articles on heatsink manufacturing and industry trends. Explore Options : Browse Xuiron's range of customized heatsinks, designed to deliver faster heat conduction and better heat dissipation. Get in Touch : Contact Xuiron for inquiries or quotes on their high-quality heat sink products, tailored to your needs.