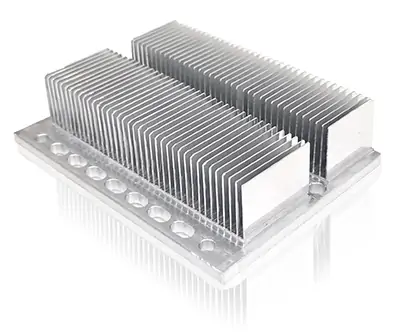

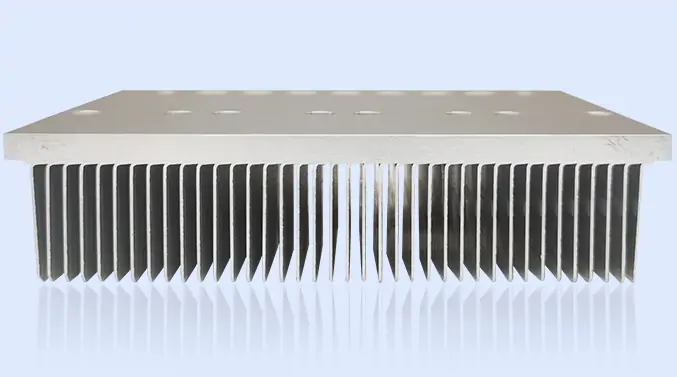

Shovel teeth heatsink

STH009

Advantages of shovel teeth heatsink

Efficient heat dissipation

The one-piece molding of the shovel teeth heatsink and the design of the shovel-teeth heat sink maintain 100% thermal conductivity of the profile.

Reliable and stable

The shovel teeth heatsink is a single piece of profile, which is strong and durable, has no risk of loosening and falling off, and can withstand long-term high heat load operation.

Highly customizable

The shovel teeth heatsink can be customized and designed according to different heat dissipation needs, such as size, shape, material, and color, and has a wider range of applications.

Low manufacturing cost

The shovel teeth heatsink requires no template costs, no minimum quantity limit, simple processing technology, and is suitable for mass production.

Advantages of shovel teeth heatsink

Efficient heat dissipation

The one-piece molding of the shovel teeth heatsink and the design of the shovel-teeth heat sink maintain 100% thermal conductivity of the profile.

Reliable and stable

The shovel teeth heatsink is a single piece of profile, which is strong and durable, has no risk of loosening and falling off, and can withstand long-term high heat load operation.

Highly customizable

The shovel teeth heatsink can be customized and designed according to different heat dissipation needs, such as size, shape, material, and color, and has a wider range of applications.

Low manufacturing cost

The shovel teeth heatsink requires no template costs, no minimum quantity limit, simple processing technology, and is suitable for mass production.

Features of shovel teeth heatsink

The shovel teeth heatsink can realize ultra-thin heat sink, ultra-small spacing, and ultra-high multiple heat dissipation structure.

- The maximum length and width of the shovel teeth heatsink is 1200*800cm;

- The minimum thickness of shovel teeth is 0.5mm;

- The minimum distance between shovel teeth is 2mm.