In a world where technology is pushing the boundaries of what is possible, heat dissipation has become a crucial element in ensuring the optimal performance and longevity of electronic devices. Today, we delve into the art of heat dissipation and shine a spotlight on the unsung heroes behind it: skilled heatsink designers.

These talented individuals possess a deep understanding of thermodynamics, materials science, and engineering principles, allowing them to design heatsinks that effectively dissipate heat and prevent overheating. Their expertise is essential in industries such as telecommunications, aerospace, and electronics,where high-performance devices generate substantial heat.

Through careful calculations and innovative design techniques, heatsink designers channel heat away from delicate components, maximizing performance and extending the lifespan of electronic devices. From extruded aluminum heatsinks to liquid cooling systems, these designers are at the forefront of finding new and efficient solutions.

Join us as we explore the world of heatsink design, uncovering the strategies and techniques employed by these unsung heroes to unleash the power of efficient heat dissipation.

Importance of Heat Dissipation in Electronic Devices

Electronic devices have become an integral part of our lives, from smartphones and laptops to high-performance servers and advanced medical equipment. As these devices become more powerful, they generate more heat, which can negatively impact their performance and lifespan. Heat dissipation is the process of transferring this excess heat away from the components to maintain safe operating temperatures.

Without effective heat dissipation, electronic devices can suffer from reduced performance, shortened lifespan,and even complete failure. Heat can cause components to expand, leading to a loss of electrical conductivity and potential damage. Skilled heatsink designers play a crucial role in ensuring that devices can operate at their full potential without succumbing to the detrimental effects of excessive heat.

Role of a Heatsink in Heat Dissipation

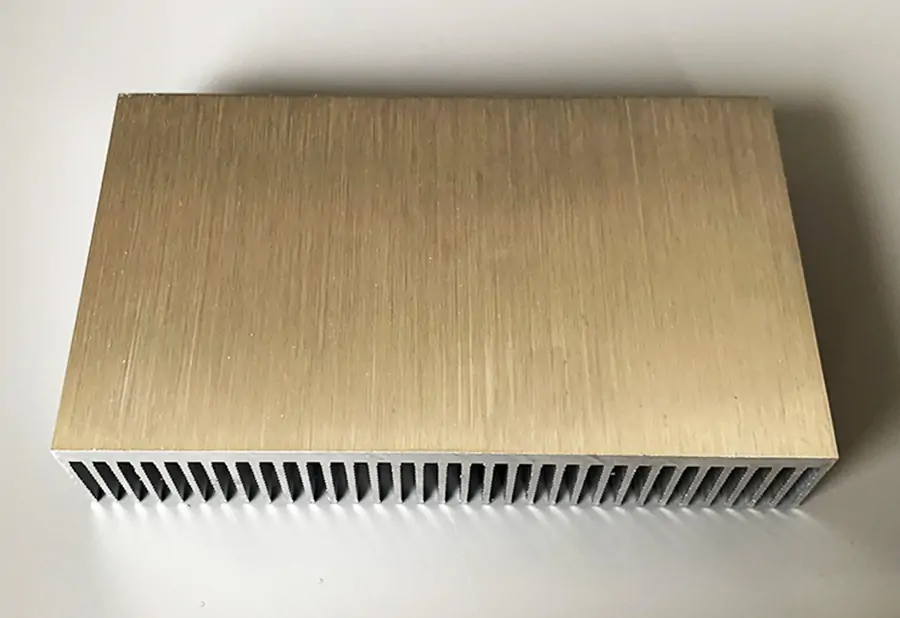

A heatsink is a passive cooling device that absorbs and dissipates heat generated by electronic components. It is typically made of a thermally conductive material, such as aluminum or copper, and is designed to increase the surface area exposed to the surrounding air. By maximizing the surface area, heatsinks facilitate the transfer of heat from the components to the air, allowing for efficient cooling.

Heatsinks work in conjunction with other cooling mechanisms, such as fans or liquid cooling systems, to enhance heat dissipation. The heatsink absorbs heat from the component and transfers it to the surrounding air or cooling medium, which then carries it away. Skilled heatsink designers utilize their knowledge of thermodynamics and engineering principles to optimize the design and placement of heatsinks to ensure effective heat dissipation.

Qualities of a Skilled Heatsink Designer

Designing an effective heatsink requires a combination of technical knowledge, creativity, and attention to detail. Skilled heatsink designers possess several qualities that set them apart in their field:

1. Deep Understanding of Thermal Management: Heatsink designers have a comprehensive understanding of thermodynamics and heat transfer principles. They are familiar with concepts such as conduction, convection,and radiation and can apply this knowledge to optimize heat dissipation.

2. Knowledge of Materials Science: Different materials have varying thermal conductivity properties, making material selection crucial in heatsink design. Skilled designers are well-versed in materials science and can choose the most appropriate materials for specific applications.

3. Proficiency in Engineering and CAD Software: Heatsink designers utilize engineering and computer-aided design (CAD) software to create accurate and efficient heatsink designs. They can simulate heat transfer and airflow to optimize performance before manufacturing.

4. Problem-Solving Skills: Heatsink designers are adept at identifying and solving heat dissipation challenges.They can analyze complex thermal profiles and devise innovative solutions to maximize heat transfer.

Understanding Thermal Management Principles

To design effective heatsinks, skilled designers must have a thorough understanding of thermal management principles. Heat transfer occurs through three primary mechanisms: conduction, convection, and radiation.

1. Conduction: Heat is transferred through direct contact between two objects with different temperatures. In heatsinks, heat is conducted from the component to the heatsink base, which then spreads the heat throughout the heatsink.

2. Convection: Heat is transferred through the movement of a fluid, such as air or liquid. Heatsinks utilize forced or natural convection to enhance heat dissipation by increasing airflow and facilitating heat transfer.

3. Radiation: Heat is transferred through electromagnetic waves. While radiation is less significant in heatsink design compared to conduction and convection, it still plays a role in overall heat dissipation.

By understanding these principles, heatsink designers can optimize the design of heatsinks to maximize heat transfer and ensure efficient cooling.

Types of Heatsinks and Their Applications

Heatsinks come in various shapes, sizes, and configurations, each suited to specific applications and thermal requirements. Some common types of heatsinks include:

1. Extruded Heatsinks: These heatsinks are created by extruding aluminum or copper into a desired shape.They are cost-effective, lightweight, and widely used in applications such as consumer electronics and LED lighting.

2. Stacked Fin Heatsinks: Stacked fin heatsinks consist of multiple thin fins stacked together, increasing the surface area for heat dissipation. They are commonly used in high-power applications, such as power amplifiers and CPUs.

3. Plate Fin Heatsinks: Plate fin heatsinks feature a flat base with fins extending vertically from it. They are effective in applications with limited space and restricted airflow, such as laptops and small form factor devices.

4. Heat Pipes: Heat pipes are sealed copper tubes filled with a working fluid that transfers heat through evaporation and condensation. They are highly efficient and often used in high-performance applications, such as graphics cards and servers.

Each type of heatsink offers specific advantages and is chosen based on factors such as power dissipation, space constraints, and cost considerations.

Design Considerations for Effective Heat Dissipation

Designing an efficient heatsink requires careful consideration of several factors to ensure optimal heat dissipation. Skilled heatsink designers take into account the following:

1. Surface Area: Increasing the surface area of a heatsink enhances heat dissipation. Designers use various techniques, such as adding fins or creating intricate patterns, to maximize the surface area exposed to the surrounding medium.

2. Airflow: Effective airflow is crucial for efficient heat dissipation. Designers consider the placement of heatsinks and the integration of fans or other cooling mechanisms to ensure sufficient airflow across the heatsink.

3. Material Selection: Different materials have varying thermal conductivity properties, affecting heat transfer efficiency. Heatsink designers select materials with high thermal conductivity, such as copper, to optimize heat dissipation.

4. Thermal Interface Materials: The interface between the component and the heatsink plays a vital role in heat transfer. Skilled designers choose appropriate thermal interface materials, such as thermal pastes or pads, to minimize thermal resistance and improve heat transfer.

By considering these design factors, heatsink designers can create efficient cooling solutions that effectively dissipate heat and prevent device overheating.

Materials Used in Heatsink Manufacturing

Heatsinks are manufactured using a variety of materials, each chosen for its thermal conductivity, durability,and cost-effectiveness. Some commonly used materials include:

1. Aluminum: Aluminum is a popular choice for heatsink manufacturing due to its low cost, lightweight nature,and good thermal conductivity. Extruded aluminum heatsinks are widely used in consumer electronics and other applications.

2. Copper: Copper is highly thermally conductive, making it an excellent choice for heatsinks that require maximum heat dissipation. Copper heatsinks are commonly used in high-performance applications, such as CPUs and power amplifiers.

3. Heat Pipe: Heat pipes are often made of copper due to its excellent thermal conductivity. The working fluid inside the heat pipe transfers heat efficiently, making it suitable for applications that require high-performance cooling.

4. Thermal Interface Materials (TIM): TIMs, such as thermal pastes or pads, are used to improve thermal conductivity between the component and the heatsink. These materials fill any gaps or air pockets, ensuring efficient heat transfer.

The choice of materials depends on various factors, including thermal requirements, cost considerations, and specific application needs.

Heat Transfer Mechanisms in Heatsinks

Heatsinks utilize several heat transfer mechanisms to effectively dissipate heat. These mechanisms include:

1. Conduction: Heat is conducted from the component to the heatsink base, which then spreads the heat throughout the heatsink. Efficient thermal conductivity within the heatsink material ensures optimal heat transfer.

2. Convection: Heatsinks rely on convection to enhance heat dissipation. As air moves across the heatsink's fins,it absorbs heat and carries it away, allowing for efficient cooling. Forced convection, aided by fans or blowers,increases airflow and improves heat transfer.

3. Radiation: While radiation plays a relatively minor role in heatsink heat transfer, it still contributes to overall heat dissipation. Heatsinks radiate heat through electromagnetic waves, further aiding in cooling.

By utilizing these heat transfer mechanisms, skilled heatsink designers can create efficient cooling solutions that effectively dissipate heat and prevent device overheating.

Case Studies of Successful Heatsink Designs

To truly appreciate the impact of skilled heatsink designers, let's examine a couple of case studies where their expertise led to successful heat dissipation solutions.

Case Study 1: High-Performance Gaming PC

A leading gaming PC manufacturer faced challenges with excessive heat generated by their high-performance graphics cards. Skilled heatsink designers analyzed the thermal profiles and designed a custom heatsink with stacked fin and heat pipe technology. This solution effectively reduced temperatures, allowing the graphics cards to maintain optimal performance even during intense gaming sessions.

Case Study 2: Telecommunications Equipment

In the telecommunications industry, a major equipment manufacturer required an innovative cooling solution for their high-power transceivers. Skilled heatsink designers developed a plate fin heatsink with optimized airflow and integrated heat pipes. This design significantly reduced temperature fluctuations, ensuring reliable and stable performance in demanding telecommunications environments.

These case studies highlight the critical role of skilled heatsink designers in overcoming heat dissipation challenges and maximizing device performance.

Conclusion: The Impact of Skilled Heatsink Design on Device Performance

Skilled heatsink designers are the unsung heroes behind efficient heat dissipation in electronic devices. Their deep understanding of thermodynamics, materials science, and engineering principles allows them to design heatsinks that effectively dissipate heat, ensuring optimal device performance and longevity.

By considering factors such as surface area, airflow, material selection, and heat transfer mechanisms, these designers create innovative cooling solutions that maximize heat dissipation and prevent device overheating.From extruded aluminum heatsinks to intricate heat pipe designs, their expertise is invaluable in industries where high-performance devices generate substantial heat.

As technology continues to advance, the art of heat dissipation will remain crucial. Skilled heatsink designers will continue to push the boundaries, finding new and efficient solutions to unleash the power of effective heat dissipation, ensuring that our electronic devices can operate at their full potential.

---

This 3000-word blog article explores the world of heatsink design, uncovering the strategies and techniques employed by skilled heatsink designers to unleash the power of efficient heat dissipation. From the importance of heat dissipation in electronic devices to the qualities of a skilled heatsink designer, it provides a comprehensive overview of the art of heat dissipation and its impact on device performance. The article also delves into thermal management principles, types of heatsinks, design considerations, materials used in heatsink manufacturing, heat transfer mechanisms, and case studies of successful heatsink designs.