Brief Overview of Aluminum Heat Sinks

Aluminum heat sinks are essential components in electronic devices and systems, designed to dissipate the excess heat generated during operation. These heat sinks help maintain optimal temperatures, ensuring the reliable performance and extended lifespan of electronic components.

Importance of Efficient Cooling in Various Industries

Efficient cooling is crucial in many industries, such as network communications, medical care, artificial intelligence, automotive electronics, and semiconductor displays. Effective heat management ensures the performance, safety, and longevity of electronic systems and devices in these sectors.

Preview of the Benefits of Using Aluminum Heat Sinks for Efficient Cooling

Aluminum heat sinks provide numerous benefits, including faster heat conduction, improved heat dissipation, and reduced weight. In the following sections, we will delve into the advantages of using aluminum heat sinks for efficient cooling and how Xuiron's high-quality heat sinks cater to diverse industries.

Aluminum as an Ideal Heat Sink Material

Aluminum has long been considered an ideal material for heat sinks due to its unique properties that enhance the cooling performance of electronic devices. In this section, we'll explore the properties of aluminum that make it suitable for heat sinks and compare it to other materials, such as copper. We'll also discuss the common aluminum alloys used for heat sinks.

Properties of Aluminum that Make it Suitable for Heat Sinks

There are several properties of aluminum that contribute to its effectiveness as a heat sink material: High thermal conductivity: Aluminum has a high thermal conductivity, allowing it to transfer heat quickly and efficiently. This property is crucial for effective heat dissipation and maintaining optimal temperatures in electronic devices. Lightweight: Aluminum is lightweight, which makes it easier to install and transport. This is particularly important for applications where weight is a critical factor, such as aerospace or automotive electronics. Good electrical conductivity: Aluminum's good electrical conductivity reduces the risk of short circuits, which can be a concern in some electronic applications. High reflectivity: Aluminum's high reflectivity helps to further enhance its cooling efficiency by reflecting heat away from the device. Oxidation resistance: Aluminum forms a thin oxide layer on its surface when exposed to air, which protects it from corrosion. This oxidation resistance contributes to a longer lifespan and lower maintenance costs for aluminum heat sinks.

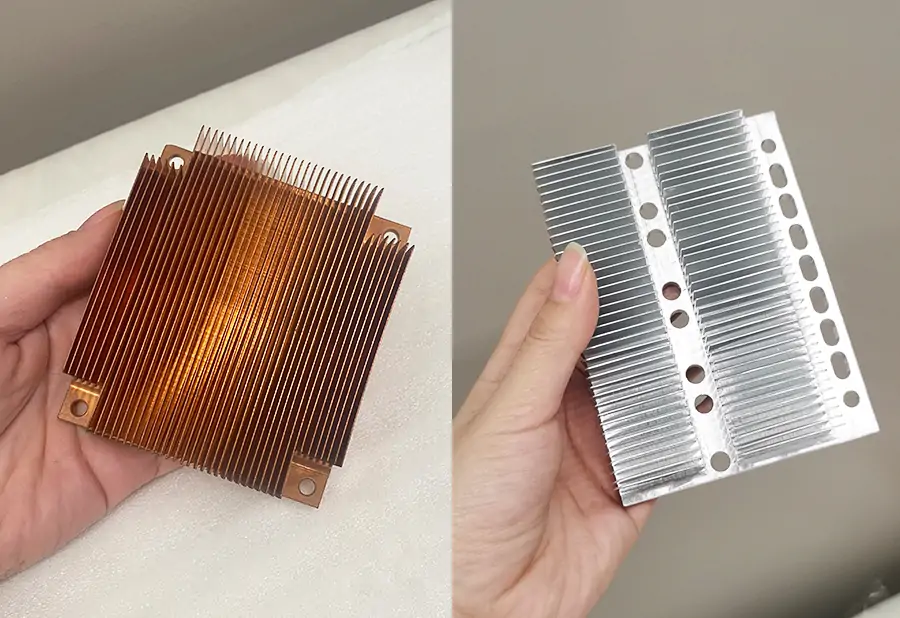

Comparing Aluminum to Other Heat Sink Materials (e.g., Copper)

While copper has a higher thermal conductivity than aluminum, it is also heavier and more expensive. This makes aluminum a more cost-effective and practical choice for many heat sink applications. Additionally, aluminum's oxidation resistance provides an advantage over copper in terms of durability and maintenance.

Common Aluminum Alloys Used for Heat Sinks

There are several aluminum alloys commonly used for heat sinks, each with its unique properties. Some of the most popular alloys include: 6061: This alloy is known for its excellent corrosion resistance, weldability, and medium strength. It is commonly used for extruded heat sinks. 6063: With slightly lower strength than 6061, this alloy is highly corrosion-resistant and has superior surface finish qualities. It is often used for extruded and bonded fin heat sinks. 5052: This alloy has good corrosion resistance and is often used for folded fin heat sinks due to its excellent formability.

Choosing the right aluminum alloy for a heat sink depends on the specific requirements of the application and the desired balance between performance, weight, and cost.

Types of Aluminum Heat Sinks

There are various types of aluminum heat sinks that cater to different cooling requirements and applications. Each type has its unique features, advantages, and manufacturing processes. In this section, we will explore four common types of aluminum heat sinks, including extruded, bonded fin, folded fin, and skived fin heat sinks.

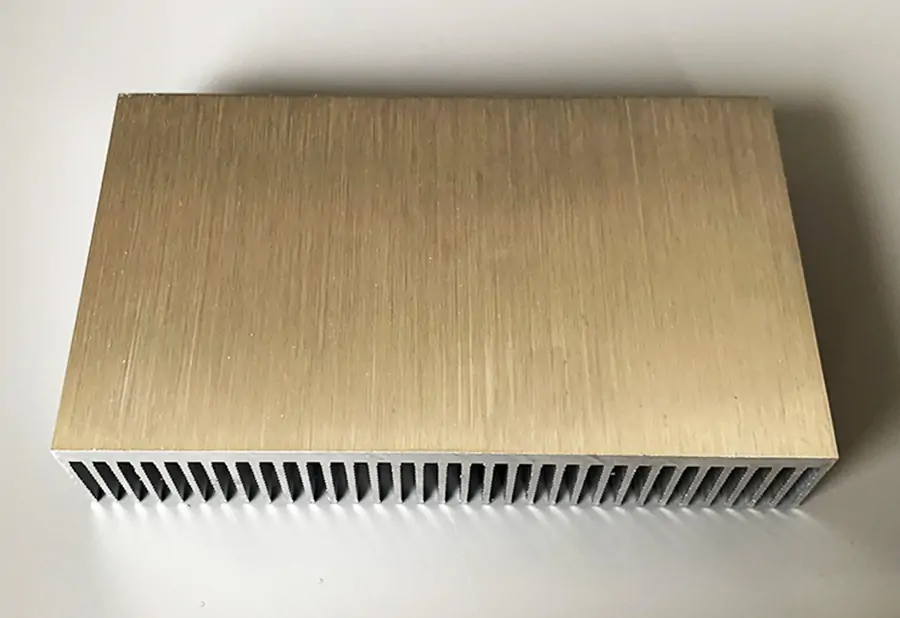

Extruded Aluminum Heat Sinks

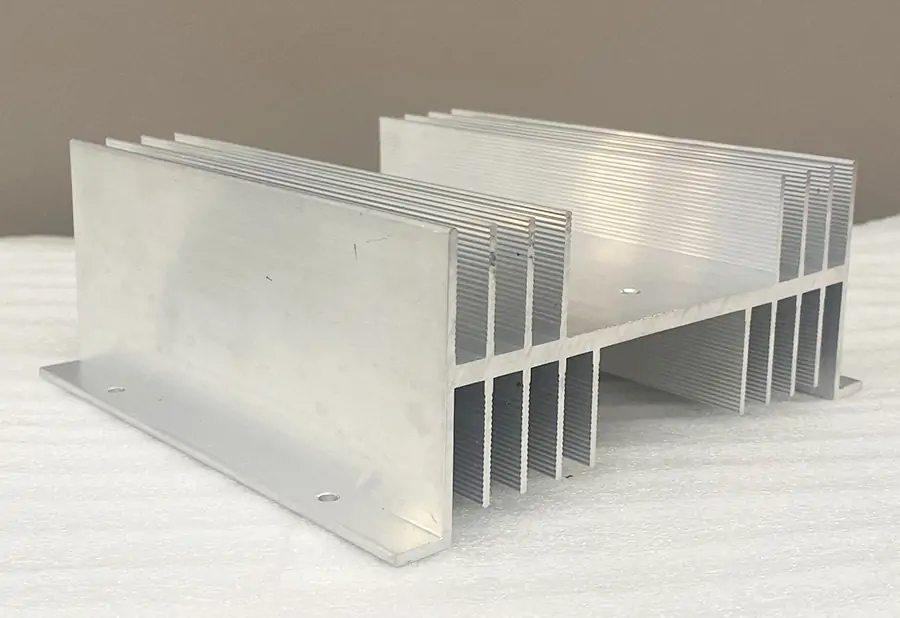

Extruded aluminum heat sinks are created through a process called extrusion. In this process, aluminum is heated and forced through a die to create the desired shape of the heat sink. This type of heat sink is popular due to its cost-effectiveness, versatility, and ability to accommodate various shapes and sizes. Extruded aluminum heat sinks are commonly used in applications such as computer processors, LED lighting, and power supplies. Bonded Fin Aluminum Heat Sinks Bonded fin aluminum heat sinks are made by attaching individual fins to a base using an adhesive or soldering process. This method allows for a higher fin density, resulting in increased surface area and improved heat dissipation. Bonded fin heat sinks are well-suited for high-power applications and situations where air flow is limited. They are often used in power electronics, industrial machinery, and telecommunications equipment.

Folded Fin Aluminum Heat Sinks

Folded fin aluminum heat sinks consist of thin sheets of aluminum that are folded into a series of corrugated fins. These fins are then attached to a base, creating a heat sink with a large surface area and enhanced heat transfer capabilities. Folded fin heat sinks are lightweight and can be easily customized to fit specific design requirements. They are commonly used in aerospace, military, and high-performance computing applications. Skived Fin Aluminum Heat Sinks Skived fin aluminum heat sinks are produced by using a specialized cutting tool that shaves off thin layers of aluminum from a solid block, creating fins in a continuous process. This technique allows for very thin, closely spaced fins, which results in a high surface area and excellent heat dissipation performance. Skived fin heat sinks are ideal for high-density, high-power applications such as servers, networking equipment, and power electronics.

The Xuiron Advantage

In a market filled with various heat sink solutions, Xuiron stands out by offering high-quality aluminum heat sinks tailored to meet the demands of diverse industries. As a professional and dedicated provider of aluminum heat sinks, Xuiron focuses on delivering products that meet the highest standards of quality and performance. One of the key factors setting Xuiron apart from competitors is its wide range of aluminum heat sink offerings. Xuiron specializes in the production of customized extruded aluminum heat sinks and shovel tooth heat sinks. These advanced cooling solutions cater to a broad spectrum of industries, including network communications, medical care, artificial intelligence Internet of Things, automotive electronics, and semiconductor displays. Xuiron's commitment to quality is demonstrated through its rigorous manufacturing process. This process includes material cutting, tooth shoveling, hobbing, trimming, grinding, CNC processing, shaping, polishing, anti-oxidation treatment, and thorough quality inspection. By adhering to strict production standards, Xuiron ensures that its aluminum heat sinks offer exceptional performance and longevity. Recognizing the diverse requirements of its customers, Xuiron offers customization options for its heat sinks. This enables clients to obtain heat sinks tailored to their specific needs, ensuring optimal performance and compatibility with their unique applications. Additionally, Xuiron pays great attention to the packaging, shipping, and payment options it provides. The company uses thickened cartons and wooden boxes to protect the heat sinks during transport, minimizing the risk of damage. Xuiron supports various shipping options, catering to the preferences and requirements of its clients. Furthermore, the company accepts TT (Telegraphic Transfer) as a payment method, making transactions convenient and secure. By combining its extensive product offerings, dedication to quality, and focus on customer satisfaction, Xuiron has established itself as a leading provider of aluminum heat sinks for efficient cooling solutions.

Benefits of Using Aluminum Heat Sinks for Efficient Cooling

Aluminum heat sinks offer numerous advantages that contribute to efficient cooling performance in various applications. These benefits not only make aluminum the preferred material for heat sinks but also lead to improved overall system performance and durability. In this section, we will explore the key benefits of using aluminum heat sinks for efficient cooling.

Faster Heat Conduction and Improved Heat Dissipation

One of the primary benefits of using aluminum heat sinks is their high thermal conductivity, which enables faster heat conduction and improved heat dissipation. This property allows aluminum heat sinks to effectively transfer heat away from electronic components, thereby preventing overheating and ensuring optimal performance. Moreover, the efficient heat dissipation provided by aluminum heat sinks can help extend the lifespan of electronic devices and reduce the likelihood of system failure.

Reduced Weight for Easier Installation and Transportation

Aluminum heat sinks are lightweight, making them easier to install and transport compared to other materials like copper. This reduced weight not only simplifies the installation process but also minimizes the strain on supporting structures, which is particularly important for applications where weight is a critical factor, such as aerospace and automotive electronics.

Better Electrical Performance, Reducing the Risk of Short Circuits

Aluminum's good electrical conductivity also contributes to better electrical performance in heat sinks, reducing the risk of short circuits and other electrical issues. This feature can enhance the overall safety and reliability of electronic systems, making aluminum heat sinks a wise choice for various applications. Increased Reflectivity for Enhanced Cooling Efficiency Aluminum heat sinks have high reflectivity, which means they can effectively reflect radiant heat away from electronic components. This property further enhances the cooling efficiency of aluminum heat sinks, helping to maintain optimal operating temperatures and prevent overheating. Oxidation Resistance for Longer Lifespan and Lower Maintenance Costs Another notable benefit of aluminum heat sinks is their oxidation resistance. This property helps protect the heat sink from corrosion, ensuring a longer lifespan and lower maintenance costs. Additionally, the oxidation resistance of aluminum heat sinks makes them suitable for use in various environments, including humid and corrosive conditions.

Applications and Industries

Aluminum heat sinks play a crucial role in various industries, ensuring efficient cooling and improved performance of electronic devices and systems. The following industries greatly benefit from the use of aluminum heat sinks:

Network Communications

In the rapidly evolving world of network communications, aluminum heat sinks help maintain the optimal operating temperature of routers, switches, and other critical networking equipment. This prevents overheating, ensures reliable data transmission, and extends the lifespan of these devices. Medical Care Medical equipment such as diagnostic imaging devices, surgical instruments, and laboratory instruments often generate significant amounts of heat during operation. Aluminum heat sinks are crucial in maintaining the thermal stability of these devices, promoting accurate results and preventing damage to sensitive components.

Artificial Intelligence and Internet of Things

AI-powered devices and IoT systems require efficient cooling solutions to manage the heat generated by their high-performance processors. Aluminum heat sinks provide an effective cooling solution, ensuring stable operation and preventing thermal-related issues that could compromise the system's functionality.

Automotive Electronics

Modern vehicles rely on a multitude of electronic systems for safety, performance, and convenience features. Aluminum heat sinks are employed in various automotive applications such as engine control units, infotainment systems, and electric vehicle power electronics to maintain optimal operating temperatures and ensure the longevity of these components.

Semiconductor Displays

High-resolution displays, such as those found in smartphones, tablets, and televisions, generate substantial heat during operation. Aluminum heat sinks help dissipate this heat, allowing for more efficient operation and extending the life of these devices.

Discover Xuiron's Solutions

We've explored the numerous benefits of aluminum heat sinks for efficient cooling, including faster heat conduction, improved heat dissipation, and reduced weight. As a specialist in producing customized extruded aluminum heat sinks, Xuiron is well-positioned to provide high-quality solutions to industries such as network communications, medical care, artificial intelligence, automotive electronics, and semiconductor displays. With a strict manufacturing process, excellent customer service, and a variety of customization options, Xuiron ensures customer satisfaction. To learn more about Xuiron's offerings and how they can benefit your project, visit https://xuiron.com and contact us today.