Heat sinks are common components in electronic devices, whose primary function is to dissipate heat away from the device, ensuring its proper operation. The manufacturing process of heat sinks is quite complex, requiring multiple steps. Here we outline the process of heat sink manufacture.

1.Material Preparation

The material for heat sinks is typically metal, such as aluminum or copper, which have excellent thermal conductivity and formability. These materials need to undergo several processes such as cutting, bending, and stretching to become various parts of the heat sink.

2.Die Processing

Heat sink manufacturing requires the use of dies, which shape the material into the desired form. Die processing is one of the key steps in heat sink manufacturing. The creation of dies requires the use of CAD software for design, taking into account factors like die strength and precision.

3.Material Processing

After die processing, the material needs further processing. During this stage, cold working is applied to the material to ensure the strength and toughness of the aluminum plate.

4.Heat Exchange Fin Manufacturing

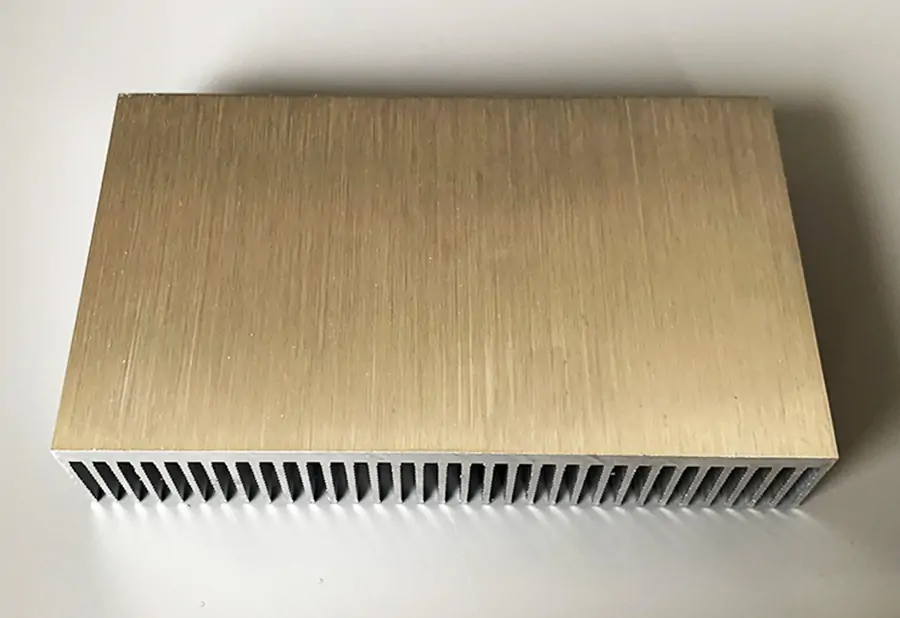

The heat exchange fins of a heat sink are one of the key components used for heat dissipation. They need to be processed using equipment such as a CNC milling machine. The shape and thickness of the heat exchange fins can affect the thermal performance of the heat sink.

5.Assembly Using Welding and Other Methods

The main body of the heat sink and other components need to be assembled using methods such as welding and fitting. Other components like fans and heat sink fins are connected using methods such as threaded connections. These assembly methods not only need to ensure assembly precision but also consider the performance and appearance of the heat sink.

6.Surface Treatment

Surface treatment is the final step in heat sink manufacturing. The surface of the heat sink undergoes anodization, improving the corrosion resistance and aesthetics of the heat sink. After anodization, the surface of the heat sink forms an oxide film, which has excellent hardness and wear resistance.

Every step in the heat sink manufacturing process needs strict control to ensure the performance and quality of the heat sink. A good heat sink requires strict requirements in terms of material selection, die design, and processing technology.