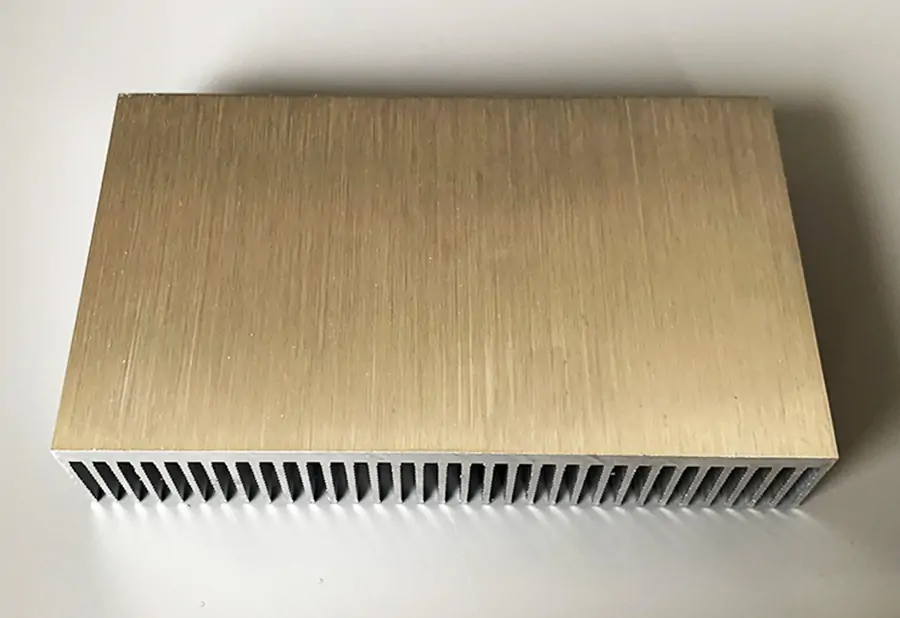

When it comes to heat sink materials, one metal reigns supreme: aluminium. In this comprehensive guide, we will explore why aluminium has become the go-to choice for heat sinks in various industries. With its exceptional thermal conductivity, lightweight nature, and cost-effectiveness, aluminium is an ideal material for dissipating heat generated by electronic components.

Not only does aluminium efficiently transfer heat away from electronic devices, but it also boasts excellent corrosion resistance and mechanical strength, making it a durable and long-lasting option. Moreover,aluminium's versatility allows for easy customization and compatibility with different manufacturing processes.

By delving into the unique properties of aluminium, we will unveil the reasons behind its dominance in the heat sink market today. From exploring its low thermal resistance and high thermal efficiency to discussing the various design options and considerations, this guide aims to equip you with the knowledge needed to make informed decisions when it comes to heat sink materials. So, join us as we dive into the world of aluminium heat sinks and discover why this metal truly reigns supreme.

Importance of Heat Sink Materials in Electronic Devices

Heat sink materials play a crucial role in electronic devices, particularly in managing thermal energy. As electronic components become smaller and more powerful, they generate higher levels of heat, which, if not effectively dissipated, can lead to reduced performance, shortened lifespan, and even system failure. This is why heat sinks are essential, as they help transfer heat away from the components, ensuring optimal operating temperatures.

Types of Heat Sink Materials

There are various materials used in heat sink manufacturing, each with its own set of properties and characteristics. Common heat sink materials include aluminium, copper, and various alloys. While each material has its advantages and limitations, aluminium stands out as the most popular choice due to its exceptional thermal conductivity and other desirable attributes.

Common Heat Sink Materials and Their Properties

Before delving into the advantages of using aluminium as a heat sink material, it's important to understand the properties of other commonly used heat sink materials. Copper, for instance, is known for its high thermal conductivity and excellent ductility, making it an excellent heat conductor. However, copper is heavier and more expensive than aluminium, which can be a disadvantage in certain applications.

Other materials, such as ceramics and graphite, offer unique properties that make them suitable for specific heat sink applications. Ceramics, for example, provide excellent electrical insulation and thermal stability,making them ideal for high-power electronic devices. Graphite, on the other hand, offers high thermal conductivity and lightweight properties, making it suitable for applications where weight is a concern.

Advantages of Using Aluminium as a Heat Sink Material

Aluminium offers a range of advantages that make it the preferred choice for heat sinks in many industries.First and foremost, aluminium possesses exceptional thermal conductivity, allowing it to efficiently transfer heat away from electronic devices. Its lightweight nature makes it ideal for applications where weight reduction is important, such as in portable electronic devices or aerospace systems.

In addition to its excellent thermal conductivity and lightweight properties, aluminium also exhibits remarkable corrosion resistance, ensuring the longevity and durability of heat sinks. This corrosion resistance is further enhanced by the natural oxide layer that forms on the surface of aluminium, providing a protective barrier against environmental factors.

Furthermore, aluminium is highly malleable, allowing for easy customization and compatibility with various manufacturing processes. This versatility enables the production of heat sinks in different shapes and sizes,catering to specific design requirements of electronic devices.

Comparison of Aluminium with Other Heat Sink Materials

While there are various materials available for heat sink manufacturing, aluminium stands out in terms of its overall performance and cost-effectiveness. Compared to copper, aluminium offers similar thermal conductivity but at a significantly lower cost. This cost advantage makes aluminium a more economical choice,especially for large-scale production.

When compared to other materials, such as ceramics and graphite, aluminium's thermal conductivity is still competitive, while offering additional benefits like lightweight and ease of customization. These factors make aluminium the preferred choice for a wide range of applications, from consumer electronics to automotive and industrial systems.

Factors to Consider When Choosing a Heat Sink Material

When selecting a heat sink material, several factors need to be considered. These include thermal conductivity,weight, cost, corrosion resistance, mechanical strength, and manufacturing feasibility. While each material has its own set of advantages and limitations, it is important to evaluate these factors in relation to the specific requirements of the application.

For example, if weight reduction is a critical factor, aluminium's lightweight nature makes it an obvious choice.On the other hand, if a high level of thermal conductivity is required, materials like copper or certain alloys may be more suitable. It is essential to strike the right balance between performance, cost, and other requirements to ensure optimal heat sink performance.

Manufacturing Processes for Aluminium Heat Sinks

Aluminium heat sinks can be manufactured using various processes, including extrusion, casting, and machining. Extrusion is the most common method due to its cost-effectiveness and flexibility in creating complex heat sink designs. This process involves forcing heated aluminium through a die to create the desired shape, resulting in a heat sink with excellent thermal conductivity and a large surface area for heat dissipation.

Casting is another manufacturing process that allows for intricate heat sink designs. This method involves pouring molten aluminium into a mold, which is then cooled and solidified to form the heat sink. While casting offers design flexibility, it may result in lower thermal conductivity compared to extrusion.

Machining, on the other hand, involves removing material from a solid block of aluminium to create the desired heat sink shape. This method is often used for low-volume production or when complex designs are required. Machined heat sinks offer precise dimensions and excellent thermal performance but can be more expensive compared to extrusion or casting.

Case Studies Showcasing the Effectiveness of Aluminium Heat Sinks

Several case studies demonstrate the effectiveness of aluminium heat sinks in different applications. For example, in the automotive industry, aluminium heat sinks are widely used to dissipate heat generated by electric vehicle batteries. These heat sinks play a crucial role in maintaining the optimal temperature range for battery performance and longevity.

In the field of consumer electronics, aluminium heat sinks are commonly found in laptops, gaming consoles,and LED lighting systems. These heat sinks ensure that the electronic components operate within their temperature limits, preventing overheating and potential damage.

Conclusion: Why Aluminium Is the Preferred Heat Sink Material

In conclusion, aluminium has rightfully earned its position as the go-to material for heat sinks in various industries. With its exceptional thermal conductivity, lightweight nature, and cost-effectiveness, aluminium offers a winning combination of performance and practicality. Its corrosion resistance, mechanical strength,and ease of customization further contribute to its popularity.

While other materials have their merits, aluminium's overall advantages make it the preferred choice for heat sink applications. Its ability to efficiently transfer heat away from electronic devices, coupled with its versatility and compatibility with different manufacturing processes, solidify its position as the reigning material in the heat sink market.

So, whether you're designing electronic devices for consumer electronics, automotive systems, or industrial applications, aluminium heat sinks provide an excellent solution for effective heat dissipation and optimal device performance. Embrace the supremacy of aluminium and unlock the full potential of your electronic designs.