Welcome to the ultimate guide to pin heat sinks, where we dive into everything you need to know about these essential cooling components. Whether you're a seasoned engineer or just starting out in the world of electronics, understanding the role of pin heat sinks is crucial for optimal cooling and device performance.

In this comprehensive guide, we'll explore the ins and outs of pin heat sinks, from their basic structure and functioning to the various types available in the market. We'll discuss the importance of heat dissipation in electronic devices, the factors to consider when choosing a pin heat sink, and the best practices for installation and maintenance.

Our goal is to equip you with the knowledge and tools to make informed decisions when it comes to selecting and implementing pin heat sinks in your designs. We'll also address frequently asked questions and debunk common misconceptions to ensure you have a clear understanding of this critical cooling solution.

So whether you're looking to enhance the performance of your computer, power amplifier, or LED lighting system, this guide has got you covered. Let's get started on the journey to achieving optimal cooling with pin heat sinks!

How Pin Heat Sinks Work

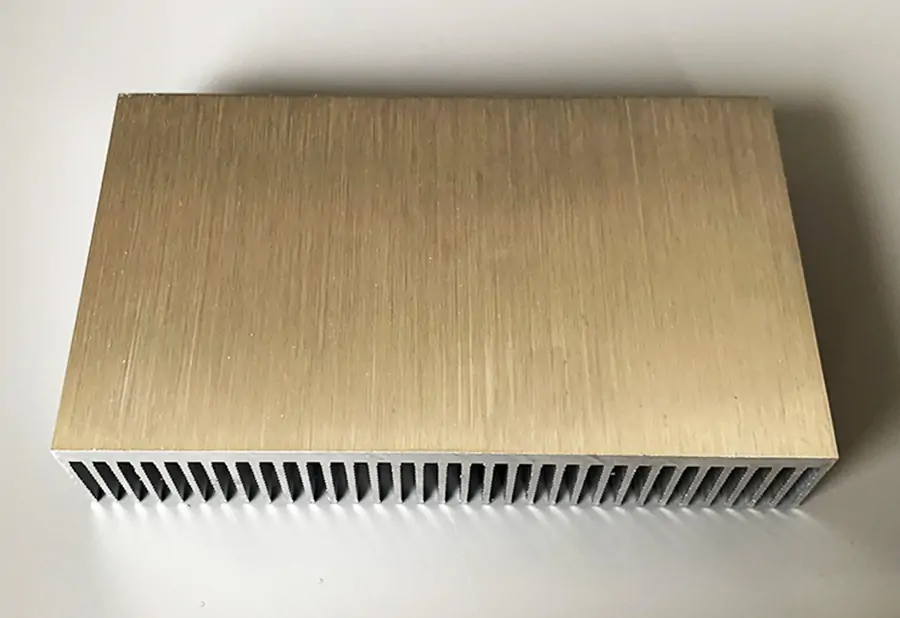

Pin heat sinks play a vital role in dissipating heat generated by electronic components. They are designed to maximize the surface area available for heat transfer, allowing for efficient cooling. The basic structure of a pin heat sink consists of a base plate and multiple pins protruding from it. These pins increase the surface area,facilitating better heat dissipation.

When an electronic component, such as a microprocessor or power transistor, generates heat during operation,it is transferred to the pin heat sink through direct contact. The pins then conduct the heat away from the component and into the surrounding air, where it is eventually dissipated. This process effectively prevents the component from overheating and ensures optimal performance.

Pin heat sinks are typically made of materials with high thermal conductivity, such as aluminum or copper.These materials enable efficient heat transfer, allowing the heat sink to effectively absorb and dissipate heat.Additionally, pin heat sinks can be customized to meet specific cooling requirements, with variations in pin density, height, and shape.

Overall, pin heat sinks provide a reliable and cost-effective solution for cooling electronic devices, ensuring their longevity and performance. Now that we understand how they work, let's explore the different types of pin heat sinks available.

Types of Pin Heat Sinks

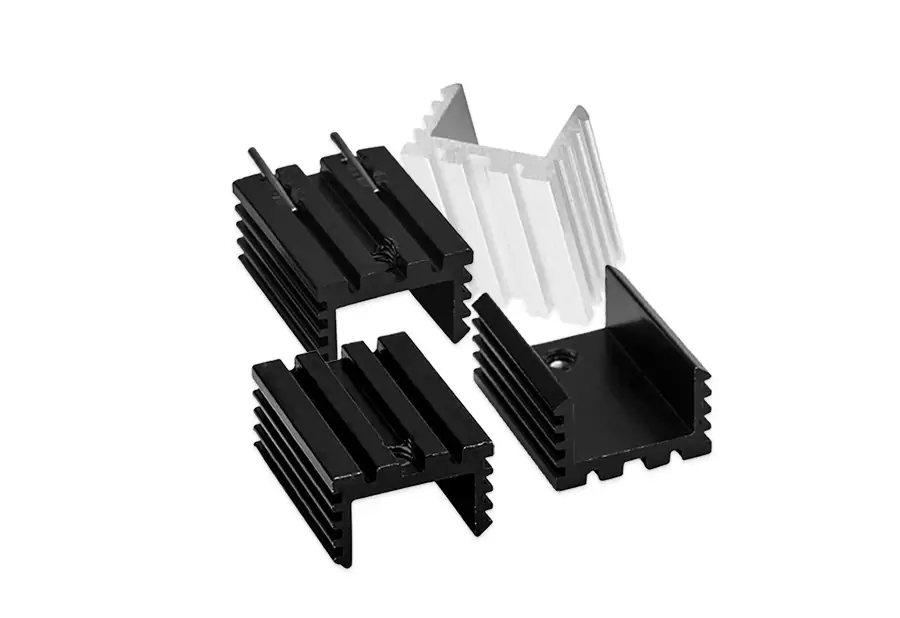

Pin heat sinks come in various shapes and sizes, each designed to suit specific cooling needs. Here are some of the most common types of pin heat sinks:

1. Straight Pin Heat Sinks: These heat sinks feature straight pins that are evenly spaced and provide a simple and efficient cooling solution. They are commonly used in applications where space is limited and airflow is restricted.

2. Tapered Pin Heat Sinks: Tapered pin heat sinks have pins that are wider at the base and gradually taper towards the top. This design allows for increased surface area and improved airflow, making them ideal for applications that require enhanced cooling performance.

3. Zigzag Pin Heat Sinks: Zigzag pin heat sinks feature a unique arrangement of pins that zigzag across the heat sink's surface. This design increases the surface area and promotes turbulent airflow, resulting in efficient heat dissipation.

4. Cross-Cut Pin Heat Sinks: Cross-cut pin heat sinks have pins that are cut at an angle to create a cross-sectional shape. This design enhances the contact area between the pins and the component, improving heat transfer and overall cooling efficiency.

5. Customized Pin Heat Sinks: In addition to the standard types mentioned above, pin heat sinks can be customized to meet specific cooling requirements. This includes variations in pin density, height, and shape,allowing for optimal cooling performance in complex electronic systems.

Now that we have explored the different types of pin heat sinks available, let's move on to the next section,where we will discuss the factors to consider when choosing a pin heat sink.

Factors to Consider When Choosing a Pin Heat Sink

When selecting a pin heat sink for your electronic device, it is essential to consider several factors to ensure optimal cooling performance. Here are some key factors to keep in mind:

1. Thermal Design Power (TDP): The TDP of the electronic component determines the amount of heat it generates. It is crucial to choose a pin heat sink with a TDP rating that exceeds the component's heat output to ensure effective heat dissipation.

2. Physical Dimensions: The size and shape of the pin heat sink should align with the available space in your electronic system. Consider the height, width, and length of the heat sink to ensure proper fitment and optimal airflow.

3. Thermal Conductivity: The thermal conductivity of the heat sink material determines how efficiently it can transfer heat. Materials with higher thermal conductivity, such as copper, provide better heat dissipation compared to materials with lower thermal conductivity, such as aluminum.

4. Airflow: The airflow within the electronic system plays a significant role in heat dissipation. Consider the system's ventilation and airflow patterns to choose a pin heat sink that complements the existing cooling setup.

5. Mounting Method: Different pin heat sinks require different mounting methods, such as clips, screws, or adhesive tapes. Consider the mounting method that best suits your application and ensure compatibility with the electronic component.

By carefully considering these factors, you can select a pin heat sink that meets your cooling requirements and ensures optimal performance of your electronic device. Now that we know how to choose the right heat sink,let's move on to the next section, where we'll discuss the installation and maintenance of pin heat sinks.

Installation and Maintenance of Pin Heat Sinks

Proper installation and maintenance of pin heat sinks are crucial to ensure their effectiveness in cooling electronic devices. Here are some best practices to follow:

1. Clean the Surface: Before installing a pin heat sink, ensure the contact surface of the electronic component is clean and free from dust, debris, or thermal interface materials. Use isopropyl alcohol or a mild solvent to remove any contaminants.

2. Apply Thermal Interface Material: Apply a thin layer of thermal interface material, such as thermal paste or thermal pads, between the electronic component and the pin heat sink. This helps improve heat transfer and fill in any microscopic gaps between the surfaces.

3. Secure the Heat Sink: Use the appropriate mounting method to secure the pin heat sink to the electronic component. Follow the manufacturer's instructions to ensure a secure and reliable installation.

4. Monitor Temperature: Regularly monitor the temperature of the electronic device to ensure the pin heat sink is effectively dissipating heat. If the temperature exceeds safe limits, consider reevaluating the heat sink's suitability or inspecting for any installation issues.

5. Clean and Maintain: Over time, dust and debris may accumulate on the pin heat sink, reducing its effectiveness. Regularly clean the heat sink using compressed air or a soft brush to remove any buildup and maintain optimal cooling performance.

By following these installation and maintenance best practices, you can maximize the effectiveness of pin heat sinks and ensure the long-term reliability of your electronic devices. Now, let's move on to the next section,where we'll explore the benefits of using pin heat sinks for cooling.

Benefits of Using Pin Heat Sinks for Cooling

Using pin heat sinks for cooling electronic devices offers numerous benefits. Here are some key advantages:

1. Efficient Heat Dissipation: Pin heat sinks provide an efficient method of dissipating heat, ensuring electronic components operate within safe temperature limits. This helps prevent performance degradation and extends the lifespan of the components.

2. Compact Design: Pin heat sinks are available in various sizes and shapes, allowing for compact designs in space-constrained electronic systems. Their ability to maximize surface area for heat transfer without adding significant bulk makes them ideal for applications where size matters.

3. Cost-Effective Solution: Pin heat sinks offer a cost-effective cooling solution compared to alternative methods such as liquid cooling or thermoelectric coolers. They are readily available, easy to install, and require minimal maintenance.

4. Versatility: Pin heat sinks can be customized to meet specific cooling requirements, making them suitable for a wide range of applications. Whether it's cooling a microprocessor, power amplifier, or LED lighting system,pin heat sinks can be tailored to provide optimal cooling performance.

5. Reliability: Pin heat sinks are a reliable cooling solution, with no moving parts or complex mechanisms. This makes them less prone to failure and ensures consistent cooling performance over time.

By leveraging the benefits of pin heat sinks, you can effectively manage heat dissipation in your electronic devices, enhancing their performance and reliability. Now, let's address some common misconceptions about pin heat sinks.

Common Misconceptions about Pin Heat Sinks

Despite their widespread use and effectiveness, there are several misconceptions surrounding pin heat sinks. Let's debunk some of the common myths:

1. Myth: More Pins Always Equal Better Cooling: While pin density plays a role in heat dissipation, more pins do not always translate to better cooling performance. Factors such as airflow, thermal conductivity, and system design also contribute to overall cooling efficiency.

2. Myth: Bigger Heat Sinks Are Always Better: Heat sink size should be chosen based on the thermal requirements of the electronic component and the available space. An oversized heat sink may restrict airflow or cause compatibility issues, negatively impacting cooling performance.

3. Myth: All Heat Sinks Are Universal: Heat sinks are not universally compatible. Each electronic component has specific cooling requirements, and the heat sink should be selected accordingly. It is essential to consider factors such as TDP, physical dimensions, and mounting method when choosing a heat sink.

4. Myth: Heat Sinks Eliminate the Need for Proper Ventilation: While heat sinks aid in heat dissipation, they are not a substitute for proper ventilation. Adequate airflow within the electronic system is crucial to ensure efficient cooling. Heat sinks should be used in conjunction with proper ventilation measures.

By dispelling these misconceptions, we can ensure a clear understanding of pin heat sinks and their role in effective cooling. Now, let's move on to the next section, where we'll explore case studies highlighting successful implementations of pin heat sinks.

Case Studies: Successful Implementations of Pin Heat Sinks

Real-world case studies can provide valuable insights into the successful implementation of pin heat sinks. Let's explore a few examples:

1. Desktop Computers: Pin heat sinks are widely used in desktop computers to cool microprocessors. By carefully selecting a heat sink with the appropriate TDP rating and physical dimensions, computer manufacturers achieve reliable cooling performance, even under heavy workloads.

2. Audio Amplifiers: Power amplifiers generate significant heat during operation. Pin heat sinks provide an efficient cooling solution, ensuring stable performance and preventing overheating. Customized heat sinks with optimized pin density and shape are often used to meet the specific cooling requirements of audio amplifiers.

3. LED Lighting Systems: LEDs can overheat and experience reduced lifespan if not properly cooled. Pin heat sinks with tailored designs help dissipate the heat generated by high-power LEDs, ensuring optimal performance and longevity.

These case studies demonstrate the versatility and effectiveness of pin heat sinks in various applications. By understanding their successful implementations, you can gain insights into potential cooling solutions for your specific needs. Now, let's move on to the next section, where we'll address frequently asked questions about pin heat sinks.

Frequently Asked Questions about Pin Heat Sinks

1. Q: Do all electronic components require a pin heat sink?

A: Not all electronic components require a pin heat sink. The need for a heat sink depends on the component's TDP and the desired operating temperature. High-power components, such as microprocessors and power transistors, often require heat sinks to prevent overheating.

2. Q: Can I reuse a pin heat sink?

A: It is generally not recommended to reuse a pin heat sink once it has been installed. The thermal interface material may be compromised during removal, affecting the heat sink's effectiveness. It is best to use a new heat sink when reinstalling or upgrading components.

3. Q: How can I determine the appropriate size of a pin heat sink for my application?

A: The appropriate size of a pin heat sink depends on factors such as the component's TDP, available space,and desired operating temperature. Consult the component's datasheet or use online calculators to determine the ideal heat sink size for your application.

4. Q: Can I stack multiple pin heat sinks for increased cooling performance?

A: While stacking multiple heat sinks may seem like a logical approach, it can negatively impact airflow and overall cooling performance. Instead, consider using a larger or more efficient single heat sink to achieve better cooling results.

5. Q: Can I overclock my electronic component with a pin heat sink?

A: Pin heat sinks can aid in cooling overclocked components, but other factors, such as voltage and power delivery, also play a significant role. It is crucial to ensure the overall system can handle the increased heat generated by overclocking.

By addressing these frequently asked questions, we hope to provide clarity on common concerns related to pin heat sinks. Now, let's move on to the conclusion, where we'll summarize the importance of proper cooling with pin heat sinks.

Conclusion: The Importance of Proper Cooling with Pin Heat Sinks

Proper cooling is essential for the optimal performance and longevity of electronic devices. Pin heat sinks play a crucial role in dissipating heat generated by electronic components, ensuring they operate within safe temperature limits. By selecting the right pin heat sink, considering factors such as TDP, physical dimensions,and thermal conductivity, you can achieve efficient heat dissipation and prevent overheating.

Remember to follow best practices when installing and maintaining pin heat sinks, such as cleaning the contact surface, applying thermal interface material, and monitoring temperature. By doing so, you can maximize the effectiveness of pin heat sinks and ensure reliable cooling performance.

In this guide, we explored the working principle of pin heat sinks, the different types available, factors to consider when choosing a heat sink, and best practices for installation and maintenance. We also highlighted the benefits of using pin heat sinks, addressed common misconceptions, and provided real-world case studies.

By equipping yourself with the knowledge gained from this guide, you can make informed decisions when it comes to selecting and implementing pin heat sinks in your electronic designs. So whether you're building a computer, designing an audio amplifier, or working on an LED lighting system, remember that pin heat sinks