Are you tired of dealing with overheating electronic devices and the subsequent decline in performance? Look no further! In this article, we will delve into the fascinating world of fin heatsinks and their impact on thermal management.

Efficient thermal management is a critical factor in ensuring optimal performance and longevity of electronic components. Fin heatsinks play a pivotal role in dissipating heat generated by these components, preventing potential damage caused by excessive temperatures.

But what exactly are fin heatsinks? How do they work? What factors affect their efficiency? We will uncover the secrets behind these essential cooling devices and shed light on their intricate design and functionality.

By understanding the science behind fin heatsinks, you'll be equipped with the knowledge to make informed decisions when it comes to selecting the right heatsink for your specific requirements. We'll explore different types of fin heatsinks and discuss their pros and cons, helping you navigate the technical jargon and choose the best option to meet your thermal management needs.

Ready to unlock the secrets of efficiency and keep your electronic devices cool? Let's dive in!

How Fin Heatsinks Work

Fin heatsinks are designed to dissipate heat from electronic components through the process of conduction,convection, and radiation. These heatsinks consist of a base, which is in direct contact with the heat source, and a series of fins that extend from the base. The fins increase the surface area available for heat transfer, allowing for more efficient cooling.

When an electronic component generates heat, it is transferred to the base of the heatsink. The base, usually made of a high thermal conductivity material such as aluminum or copper, quickly absorbs the heat. The fins,which are thin and usually spaced closely together, provide additional surface area for heat dissipation.

As air passes over the fins, it absorbs the heat and carries it away from the heatsink. This process is known as convection. The larger the surface area and the more airflow, the better the heat dissipation. In some cases,fans or other cooling mechanisms are used to enhance the airflow and further improve the cooling performance.

Importance of Efficient Thermal Management

Efficient thermal management is crucial for the reliable operation and longevity of electronic components.Excessive heat can lead to a variety of problems, including reduced performance, premature failure, and increased energy consumption.

When electronic components operate at high temperatures, their performance can be significantly affected.Processors, for example, may throttle their speed to prevent overheating, resulting in slower performance.Additionally, high temperatures can cause electronic components to become unstable, leading to system crashes and data loss.

Furthermore, prolonged exposure to high temperatures can shorten the lifespan of electronic components.Heat can degrade the materials used in the components, leading to solder joint failures, capacitor leakage, and other reliability issues. By effectively managing the heat generated by electronic components, fin heatsinks help extend their operational lifespan.

Factors Affecting the Performance of Fin Heatsinks

Several factors influence the performance of fin heatsinks. Understanding these factors is essential for selecting the right heatsink for your specific application. Let's explore them in more detail:

### 1. Surface Area

The surface area of the heatsink directly affects its heat dissipation capability. The larger the surface area, the more efficiently heat can be transferred to the surrounding environment. Fins are designed to increase the surface area, but their shape, size, and density all play a role in determining the overall effectiveness of the heatsink.

### 2. Material

The material used in the construction of the heatsink is another critical factor. Materials with high thermal conductivity, such as copper and aluminum, are commonly used for their excellent heat transfer properties. The choice of material depends on various factors, including cost, weight, and application requirements.

### 3. Airflow

Airflow is essential for effective heat dissipation. The movement of air over the heatsink helps carry away the heat. Factors such as fan placement, fan speed, and obstructions can significantly impact the airflow and,consequently, the cooling performance of the heatsink.

### 4. Mounting

The method of mounting the heatsink to the heat source is also crucial. A proper thermal interface material,such as thermal paste or thermal pads, is used to ensure maximum contact and minimize thermal resistance between the heatsink and the component.

### 5. Ambient Temperature

The ambient temperature, or the temperature of the surrounding environment, can affect the cooling performance of the heatsink. Higher ambient temperatures reduce the temperature difference between the heatsink and the environment, making it more challenging to dissipate heat effectively.

Types of Fin Heatsinks and Their Applications

Fin heatsinks come in various shapes, sizes, and designs, each suited for specific applications. Let's explore some of the most common types of fin heatsinks and their applications:

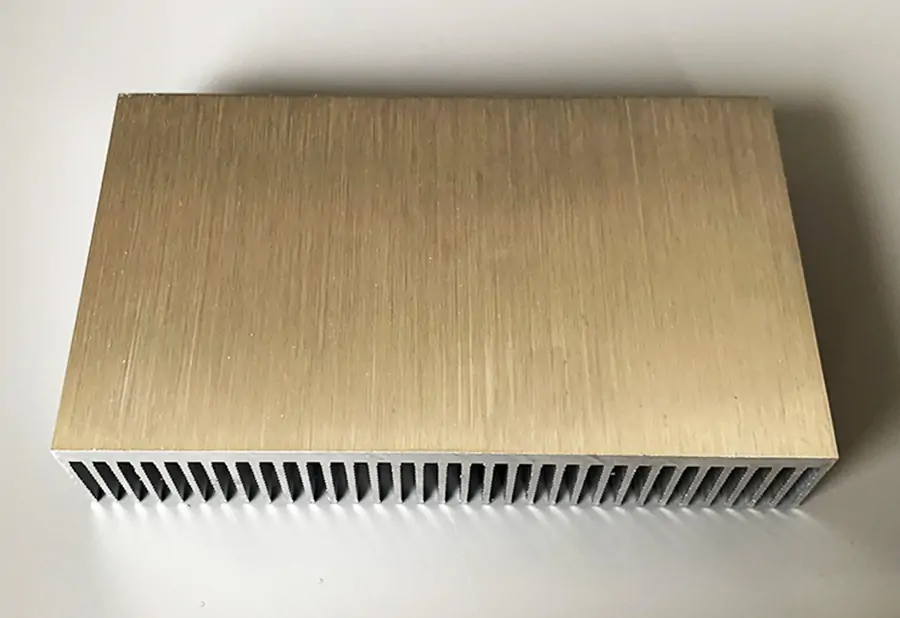

### 1. Extruded Heatsinks

Extruded heatsinks are the most common type of heatsinks and are widely used in various electronic devices.

They are created by extruding aluminum or copper into a specific shape and then cutting fins into the extrusion. Extruded heatsinks are cost-effective, versatile, and available in a wide range of sizes and configurations.

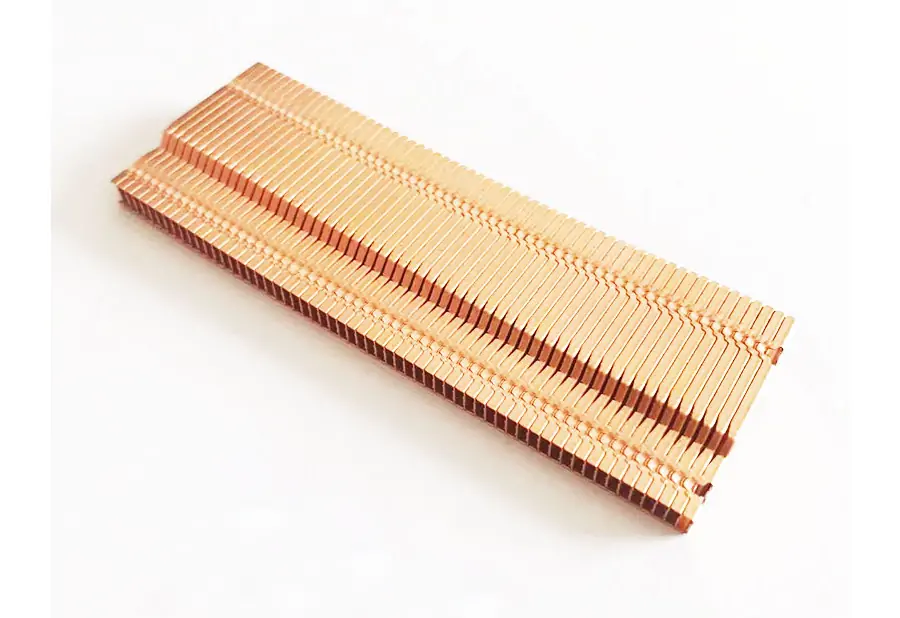

### 2. Bonded Fin Heatsinks

Bonded fin heatsinks are constructed by bonding individual fins to a base using epoxy or other adhesives. This design allows for greater flexibility in customizing the heatsink's shape and size. Bonded fin heatsinks are commonly used in applications where high turbulence airflow or low-pressure drop is required.

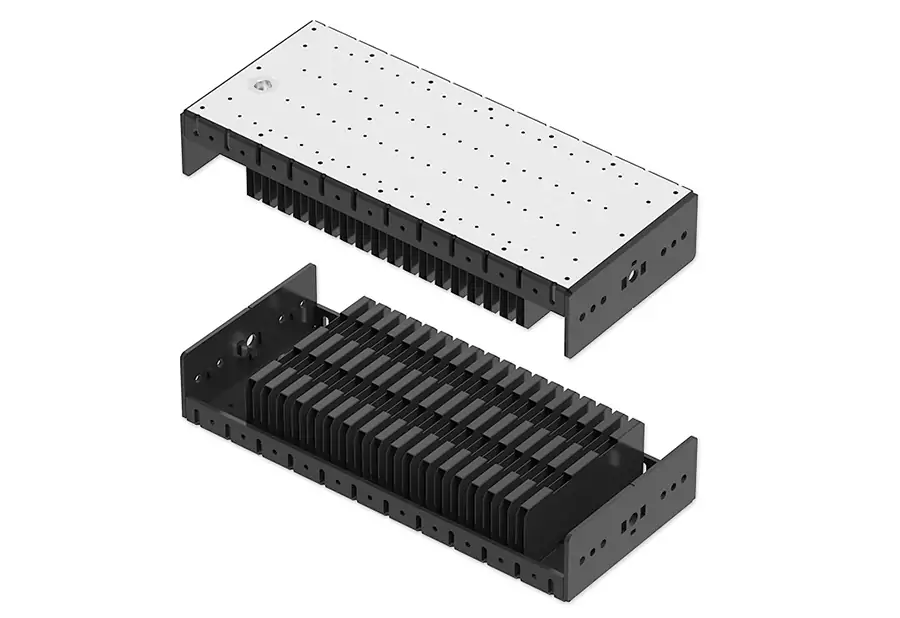

### 3. Stacked Fin Heatsinks

Stacked fin heatsinks consist of multiple layers of fins stacked on top of each other. This design increases the surface area without significantly increasing the footprint of the heatsink. Stacked fin heatsinks are often used in compact electronic devices where space is limited.

### 4. Pin Fin Heatsinks

Pin fin heatsinks feature a dense array of cylindrical pins that extend from the base. These pins increase the surface area and enhance heat dissipation. Pin fin heatsinks are commonly used in applications where space is limited, and airflow is restricted, such as in laptops and small form factor devices.

### 5. Liquid Cooled Heatsinks

Liquid cooled heatsinks utilize a combination of liquid coolant and fins to dissipate heat. These heatsinks are commonly used in high-performance applications where traditional air cooling methods are insufficient.Liquid cooled heatsinks can effectively manage high heat loads and provide superior cooling performance.

Choosing the Right Fin Heatsink for Your Needs

Selecting the right fin heatsink for your specific application requires careful consideration of several factors.Here are some key points to keep in mind when choosing a fin heatsink:

### 1. Heat Load

The heat load, or the amount of heat generated by the electronic component, is a critical factor in determining the size and type of heatsink required. It is essential to accurately calculate the heat load to ensure the heatsink can effectively dissipate the heat.

### 2. Space Constraints

Consider the available space for the heatsink. Different types of heatsinks have varying footprints, and it's important to choose one that fits within the constraints of your application.

### 3. Airflow Conditions

Evaluate the airflow conditions in your application. If there is limited airflow, consider heatsinks with higher fin density or alternative cooling methods, such as liquid cooling.

### 4. Noise Considerations

If noise is a concern, opt for larger heatsinks with low-speed fans or passive heatsinks that rely solely on natural convection for cooling.

### 5. Cost and Manufacturing Constraints

Consider the cost implications and manufacturing constraints associated with the heatsink you choose.Extruded heatsinks are generally more cost-effective, while custom designs may require additional manufacturing processes and incur higher costs.

Common Challenges in Using Fin Heatsinks and How to Overcome Them

While fin heatsinks are effective cooling solutions, they are not without their challenges. Here are some common challenges you may encounter when using fin heatsinks and how to overcome them:

### 1. Insufficient Airflow

Insufficient airflow can hinder the cooling performance of fin heatsinks. To overcome this challenge, consider using fans or other cooling mechanisms to enhance the airflow. Additionally, ensure that the heatsink is properly mounted and aligned with the airflow direction to maximize its effectiveness.

### 2. Thermal Interface Resistance

Thermal interface resistance refers to the resistance to heat transfer between the heatsink and the component.To minimize thermal resistance, use high-quality thermal interface materials, such as thermal paste or thermal pads, to ensure maximum contact between the heatsink and the component.

### 3. Limited Space

Limited space can pose challenges when selecting a fin heatsink. In such cases, consider using compact heatsinks or alternative cooling methods, such as liquid cooling or heat pipes, which can provide effective heat dissipation within limited space constraints.

### 4. Weight Considerations

In applications where weight is a concern, consider using lightweight materials such as aluminum for the heatsink construction. This allows for effective heat dissipation while minimizing the overall weight of the device.

Innovations in Fin Heatsink Technology

As technology continues to advance, so does the design and functionality of fin heatsinks. Here are some notable innovations in fin heatsink technology:

### 1. Microfin Heatsinks

Microfin heatsinks feature smaller and more closely spaced fins, allowing for increased surface area and improved heat dissipation. These heatsinks are particularly effective in applications where space is limited or where high-performance cooling is required.

### 2. Vapor Chamber Heatsinks

Vapor chamber heatsinks utilize a sealed chamber filled with a coolant that vaporizes and condenses to transfer heat. This technology provides excellent heat spreading capabilities and is commonly used in high-performance applications where traditional heatsinks may be insufficient.

### 3. Heat Pipe Heatsinks

Heat pipe heatsinks utilize heat pipes, which are sealed copper tubes containing a small amount of fluid. The fluid absorbs heat from the heat source, vaporizes, and then condenses at a cooler section of the pipe. This process efficiently transfers heat away from the component and enhances cooling performance.

Case Studies: Real-World Examples of Successful Thermal Management with Fin Heatsinks

To further illustrate the effectiveness of fin heatsinks in real-world applications, let's explore a couple of case studies:

### 1. High-Performance Gaming Laptop

A leading gaming laptop manufacturer implemented a custom-designed fin heatsink to manage the heat generated by high-performance processors and graphics cards. The fin heatsink, combined with high-speed fans, effectively dissipated the heat, allowing the laptop to maintain optimal performance even during extended gaming sessions.

### 2. LED Lighting System

A company specializing in LED lighting solutions utilized extruded heatsinks to manage the heat generated by their high-power LED modules. The extruded heatsinks, with their large surface area and efficient heat dissipation capabilities, ensured that the LED modules operated within their specified temperature range,resulting in improved performance and increased lifespan.

Conclusion: Maximizing Efficiency with Fin Heatsinks

Efficient thermal management is crucial for ensuring optimal performance and reliability of electronic components. Fin heatsinks play a vital role in dissipating heat and preventing potential damage caused by excessive temperatures.

By understanding the science behind fin heatsinks and considering factors such as surface area, material,airflow, and mounting, you can select the right heatsink for your specific requirements. With advancements in technology, innovative designs such as microfin heatsinks, vapor chamber heatsinks, and heat pipe heatsinks offer even greater cooling performance.

So, whether you're designing a high-performance gaming system or an energy-efficient LED lighting solution,unlocking the secrets of efficiency with fin heatsinks will help keep your electronic devices cool and maximize their lifespan.

Choose wisely, and enjoy the benefits of efficient thermal management!