Heat sinks play a vital role in electronics by managing heat and preventing overheating, which can lead to performance issues, component damage, and system failure. These essential components are designed to dissipate heat generated by electronic devices, ensuring optimal performance and longevity. Xuiron, a professional

heat sink manufacturing

company, specializes in producing high-quality heat sinks that cater to various industries, showcasing their expertise in this critical field.

A heat sink is a crucial component in electronics that is designed to manage and dissipate heat generated by various components within a device. The primary purpose of a heat sink is to maintain a stable temperature within the device, preventing overheating and ensuring optimal performance. The role of heat sinks in electronic devices is essential, as they help to regulate the temperature of critical components such as processors, transistors, and integrated circuits. By effectively dissipating the heat generated during operation, heat sinks play a vital role in preventing performance issues and potential damage to the components. When heat sinks are not functioning properly or are absent altogether, the consequences can be severe. Overheating can lead to performance issues such as slowdowns, crashes, and even permanent damage to the components, potentially resulting in system failure. Consequently, understanding the purpose and functioning of heat sinks is crucial for anyone working with or designing electronic devices.

Materials Used in Heat Sinks

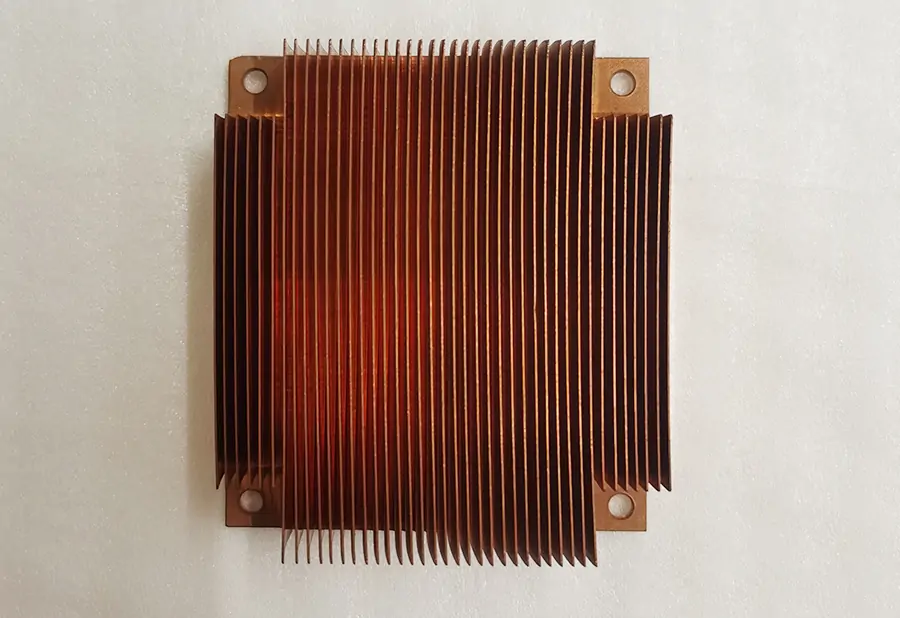

The choice of materials used in heat sinks is crucial to their performance and effectiveness. The most common heat sink materials are aluminum and copper , both of which possess properties that make them suitable for this purpose.

Properties of Aluminum and Copper in Heat Sinks

Aluminum and copper are chosen for heat sinks due to their excellent heat conduction and dissipation properties. Aluminum is a lightweight material with good thermal conductivity, making it a popular choice for many applications. It also has the added benefit of being more cost-effective than copper. On the other hand, copper has even better thermal conductivity than aluminum, which allows it to dissipate heat more efficiently. However, copper is heavier and more expensive than aluminum. When selecting the right material for a heat sink, it is essential to consider factors such as the device's operating environment, the specific heat sink requirements, and any budget constraints.

Xuiron's Use of High-Quality Materials in Their Heat Sinks

Xuiron, a professional heat sink manufacturing company, specializes in producing high-quality, customized heat sinks made of aluminum or copper. Their manufacturing process ensures that the materials used in their heat sinks meet the highest standards of quality and performance. By using premium materials, Xuiron is able to provide their customers with heat sinks that effectively manage and dissipate heat in their electronic devices, helping to prevent overheating and potential damage to the components.

How Does a Heat Sink Work?

Heat sinks play a crucial role in managing and dissipating heat generated by electronic components. Understanding the basic principles of heat conduction and dissipation, the role of heat sink structure, and the importance of proper installation is essential for optimal performance.

A. Basic Principle of Heat Conduction and Dissipation in Heat Sinks

Heat sinks function by conducting heat away from electronic components and dissipating it into the surrounding air. They achieve this through the use of materials with high thermal conductivity, such as aluminum or copper. These materials absorb the heat generated by the components and transfer it to the heat sink's surface. From there, the heat is dissipated into the air, either through natural convection or forced air cooling, depending on the type of heat sink used.

B. Role of Heat Sink Structure in Improving Heat Management

The structure of a heat sink is critical for its effectiveness in managing heat. Heat sinks come in various shapes and sizes, designed to maximize the surface area exposed to the air. By increasing the surface area, heat sinks can dissipate more heat, resulting in more effective cooling. Some common heat sink structures include pin-fin, plate-fin, and cold plates. These designs facilitate efficient heat transfer and dissipation, ensuring that electronic components remain within safe operating temperatures.

C. Importance of Proper Heat Sink Installation

Proper heat sink installation is crucial for optimal heat management. If a heat sink is not correctly installed or is not in full contact with the component it is meant to cool, the heat transfer process will be compromised, resulting in inadequate cooling and potential overheating. To ensure effective heat dissipation, it is essential to use appropriate mounting hardware, thermal paste, or thermal pads to secure the heat sink to the component and maintain proper contact. Proper installation not only ensures efficient heat transfer but also extends the life of electronic components and prevents potential performance issues.

Types of Heat Sinks

Heat sinks play a crucial role in managing heat generated by electronic components. There are three main types of heat sinks: active heat sinks, passive heat sinks, and hybrid heat sinks. Each type has its unique features and applications, making them suitable for different electronic devices.

Active heat sinks

Active heat sinks utilize external power sources, such as fans or thermoelectric coolers, to enhance heat dissipation. They are highly efficient and suitable for electronic devices that generate a significant amount of heat. However, their reliance on external power sources may make them less energy-efficient compared to passive heat sinks.

Passive heat sinks

Passive heat sinks do not require any external power source. They rely on the natural process of convection and heat dissipation through the heat sink material and structure. Although less efficient than active heat sinks, passive heat sinks have the advantage of being quiet, low-cost, and more energy-efficient.

Hybrid heat sinks

Hybrid heat sinks combine the best features of both active and passive heat sinks, providing efficient heat dissipation while maintaining energy efficiency. They often use a combination of fans and heat sink materials to manage heat effectively in high-performance electronic devices.

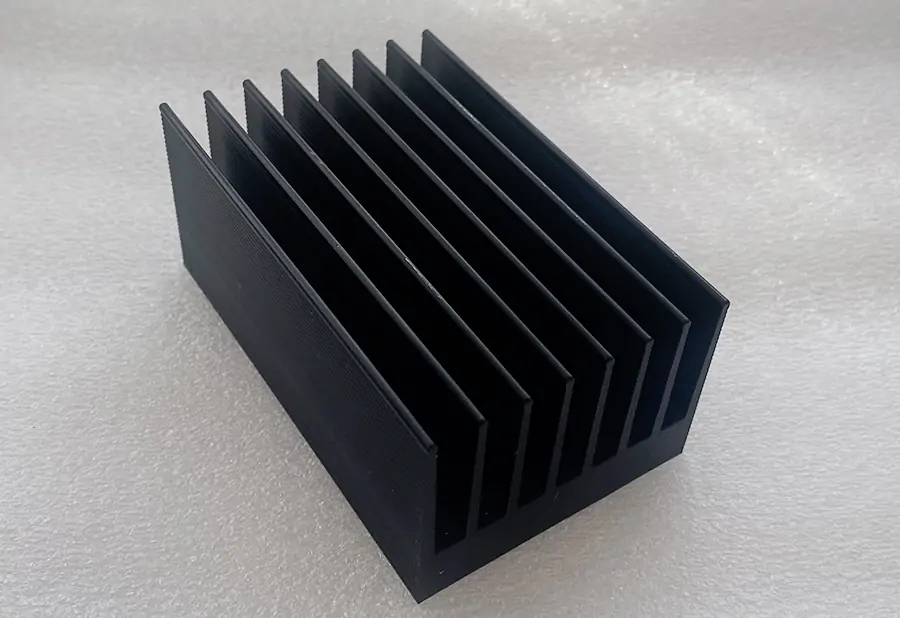

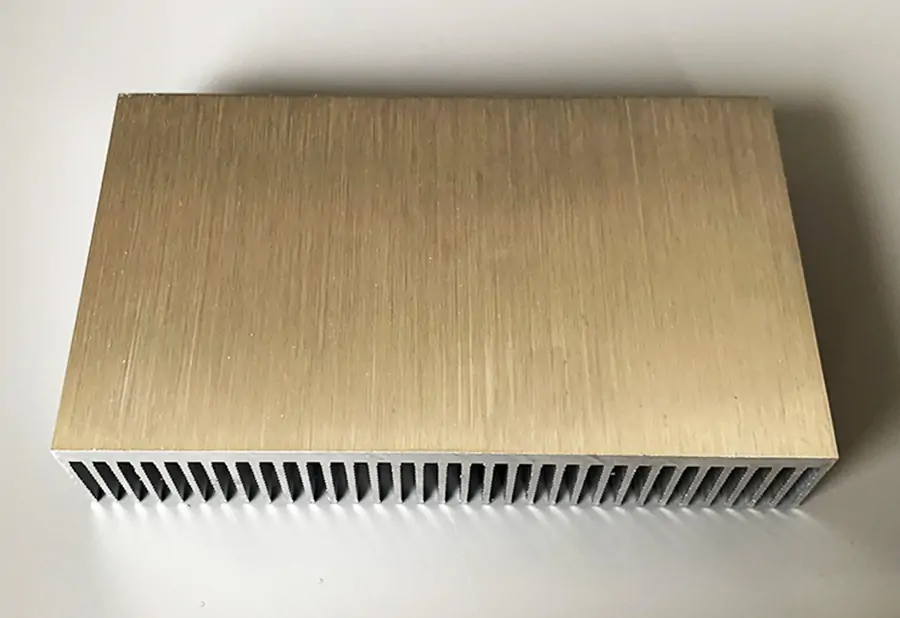

Examples of Xuiron's customized extruded heat sinks and shovel tooth heat sinks

Xuiron specializes in producing high-quality customized extruded heat sinks and shovel tooth heat sinks. These heat sinks are tailored to meet the specific requirements of various industries, such as network communications, medical care, artificial intelligence Internet of Things, automotive electronics, and semiconductor displays. By using premium materials and following a strict manufacturing process, Xuiron ensures that their heat sinks efficiently manage heat and prolong the lifespan of electronic components.

Comparisons between Heat Sinks and Other Heat Dissipation Devices

In addition to heat sinks, there are various other heat dissipation devices used in electronic systems. These devices serve different purposes and have unique advantages and drawbacks. In this section, we will compare heat sinks to other common heat dissipation devices, including plate heat exchangers, cooling radiators, thermal paste, thermal conductive sheets, and vapor chambers.

Plate Heat Exchangers

Plate heat exchangers are used to transfer heat between two fluids without direct contact. They consist of a series of metal plates that are separated by a small gap, allowing the fluids to flow between them. Plate heat exchangers offer efficient heat transfer, but their use is typically limited to liquid cooling systems, whereas heat sinks can be used in both air and liquid cooling applications.

Cooling Radiators

Cooling radiators are commonly used in liquid cooling systems, such as those found in automobiles. They consist of a series of tubes and fins that allow heat to transfer from the coolant to the air. Although radiators are effective in dissipating heat, they require a liquid coolant and a pump to function, making them more complex and potentially less reliable than heat sinks.

Thermal Paste

Thermal paste, also known as thermal grease or compound, is a substance that is applied between a heat sink and the heat-producing component. It improves the thermal conductivity between the two surfaces by filling in any gaps or irregularities. While thermal paste is essential for ensuring optimal heat transfer, it is not a standalone heat dissipation device and must be used in conjunction with a heat sink or other cooling solution.

Thermal Conductive Sheets

Thermal conductive sheets are thin, flexible materials that are used to improve heat transfer between surfaces. They can be made of various materials, such as graphite or silicone, and are often used in situations where space is limited or a traditional heat sink is not feasible. While thermal conductive sheets can help improve heat management, they typically do not offer the same level of cooling performance as heat sinks.

Vapor Chambers

Vapor chambers are advanced heat dissipation devices that use phase change cooling to transfer heat. They consist of a sealed chamber filled with a small amount of liquid, which vaporizes when heated. The vapor then condenses on a cooler surface, releasing the heat and returning to its liquid state. Vapor chambers offer excellent heat transfer capabilities but can be more expensive and less common than heat sinks. In conclusion, heat sinks remain a widely used and reliable solution for managing heat in electronic systems. While other heat dissipation devices have their advantages, heat sinks provide a versatile and efficient cooling option that can be tailored to meet the specific needs of various applications.

Xuiron's Manufacturing Process

At Xuiron, the manufacturing process for heat sinks is meticulously designed to ensure the highest quality products. The company adheres to a strict manufacturing process that involves several steps to produce heat sinks that meet and exceed customer expectations. This commitment to excellence is evident in the company's focus on customer satisfaction and their industry expertise.

Overview of the Strict Manufacturing Process

Xuiron's heat sink manufacturing process is characterized by its rigorous standards, which are aimed at producing high-quality, reliable, and efficient heat sinks. The process begins with the selection of high-quality materials such as pure aluminum or copper, chosen for their exceptional heat conduction and dissipation properties.

Steps Involved in Producing High-Quality Heat Sinks

The manufacturing process at Xuiron involves a series of steps, each carefully executed to ensure the final product meets the company's high standards.

These steps include: Material cutting: The chosen material is cut into the desired size and shape for the specific heat sink design. Tooth shoveling: The material is further shaped to create the distinct tooth-like structures that are integral to the heat sink's design and function. Hobbing: The teeth are then refined and fine-tuned to ensure optimal heat dissipation performance. Trimming: Any excess material is removed, and the heat sink is shaped to its final form. Grinding: The heat sink undergoes a grinding process to achieve a smooth, polished finish. CNC processing: Computerized machining techniques are used to achieve precise and accurate final dimensions. Shaping: The heat sink is shaped to fit its intended application and ensure effective heat dissipation. Polishing: The heat sink is polished to achieve a professional, high-quality appearance. Anti-oxidation treatment: The heat sink undergoes a treatment process to protect it from oxidation and ensure its longevity.

Quality Inspection and Commitment to Customer Satisfaction

Throughout the manufacturing process, Xuiron conducts thorough quality inspections to ensure that each heat sink meets the company's high standards for performance and reliability. This commitment to quality is a testament to Xuiron's dedication to providing their customers with top-notch heat sinks that deliver excellent performance and contribute to the overall success of their electronic devices.

Applications of Heat Sinks

Heat sinks play a crucial role in a wide range of industries, helping to manage and dissipate heat generated by electronic components. Some of the major industries that use heat sinks include network communications, medical care, artificial intelligence Internet of Things (AIoT), automotive electronics, and semiconductor displays. In the field of network communications, heat sinks are essential for preventing overheating in devices such as routers, switches, and servers. These components require efficient heat management to maintain optimal performance and prevent system failure. Medical care is another industry where heat sinks are indispensable. High-precision medical equipment generates significant amounts of heat, and proper heat management is necessary to ensure accurate readings and the overall safety of both patients and healthcare professionals. As the AIoT industry continues to grow, so does the demand for effective heat sinks. Devices that utilize artificial intelligence and the Internet of Things generate a significant amount of heat, making heat sinks vital for maintaining the performance and longevity of these devices. Automotive electronics, such as electric vehicle charging stations and power control modules, also rely on heat sinks to prevent overheating and ensure the safety and efficiency of the systems. Proper heat management is crucial in preventing malfunctions and prolonging the lifespan of these components. Finally, the semiconductor display industry, which includes LED screens and other advanced display technologies, requires heat sinks to manage the heat generated during operation. Effective heat dissipation is essential for maintaining the performance and lifespan of these displays. In summary, heat sinks are vital components in various industries, providing efficient heat management and preventing overheating in electronic devices. Their importance cannot be overstated, as they help ensure the optimal performance, safety, and longevity of a wide range of products and systems.

Xuiron's Customer Service and Customization Options

Understanding the diverse needs of its clients, Xuiron prioritizes excellent customer service and offers a range of customization options for its heat sinks. This not only ensures that clients receive products tailored to their specific requirements but also contributes to overall customer satisfaction.

Enhanced Packaging and Shipping Options

Xuiron goes the extra mile to ensure that its products are delivered safely and efficiently. They utilize thickened cartons and wooden boxes for packaging, thereby providing added protection to the heat sinks during transit. Moreover, the company offers various shipping options to suit the preferences and convenience of its clients.

Customization Options for Heat Sinks

Recognizing that different electronic devices require unique heat sink solutions, Xuiron provides customization options to cater to the specific needs of each client. With their expertise in heat sink manufacturing , the company works closely with clients to create heat sinks that meet the desired specifications and performance requirements.

Payment Methods and Production Lead Time

Xuiron strives to make the entire process, from ordering to payment, as seamless as possible. They support TT (Telegraphic Transfer) as their preferred payment method, ensuring a secure and efficient transaction process. Production lead time depends on the order quantity and the specific products being manufactured, with Xuiron committed to delivering high-quality heat sinks within the specified schedule.

In this article, we've discussed the importance of heat sinks in electronics, their role in managing and dissipating heat, and the materials used in their construction. Xuiron, a professional heat sink manufacturing company, specializes in the production of customized extruded heat sinks and shovel tooth heat sinks, following a strict manufacturing process to ensure high-quality products. To learn more about heat sinks and Xuiron's manufacturing services, visit their website and explore the variety of solutions they offer.