When it comes to keeping electronic devices cool, pin heatsinks play a vital role. These ingenious devices may seem simple on the surface, but they are essential for preventing overheating and maintaining optimal performance. In this article, we will dive deep into the world of pin heatsinks, unraveling their mystery and shedding light on why they are so crucial for electronics.

Pin heatsinks work on the principle of heat dissipation through conduction and convection. By providing a large surface area in a compact form, these metal pins efficiently absorb and transfer heat away from electronic components. This helps prevent damage caused by excessive temperature build-up, prolonging the lifespan of devices and ensuring their efficient operation.

In addition to their cooling function, pin heatsinks are also designed to be lightweight and easy to install. This makes them a popular choice for a wide range of applications, from computer processors and graphics cards to power supplies and LED lights.

So, if you've ever wondered how pin heatsinks work and why they are an essential component of electronics,join us as we unravel the mystery behind these remarkable devices.

The Importance of Heat Dissipation in Electronics

Electronic devices generate heat during operation, and if not properly managed, this heat can lead to performance issues, reduced lifespan, and even complete failure of the device. Heat dissipation is therefore a critical aspect of electronics design, and pin heatsinks are an effective solution to address this challenge.

Pin heatsinks work on the principle of heat dissipation through conduction and convection. By providing a large surface area in a compact form, these metal pins efficiently absorb and transfer heat away from electronic components. This helps prevent damage caused by excessive temperature build-up, prolonging the lifespan of devices and ensuring their efficient operation.

How Pin Heatsinks Work

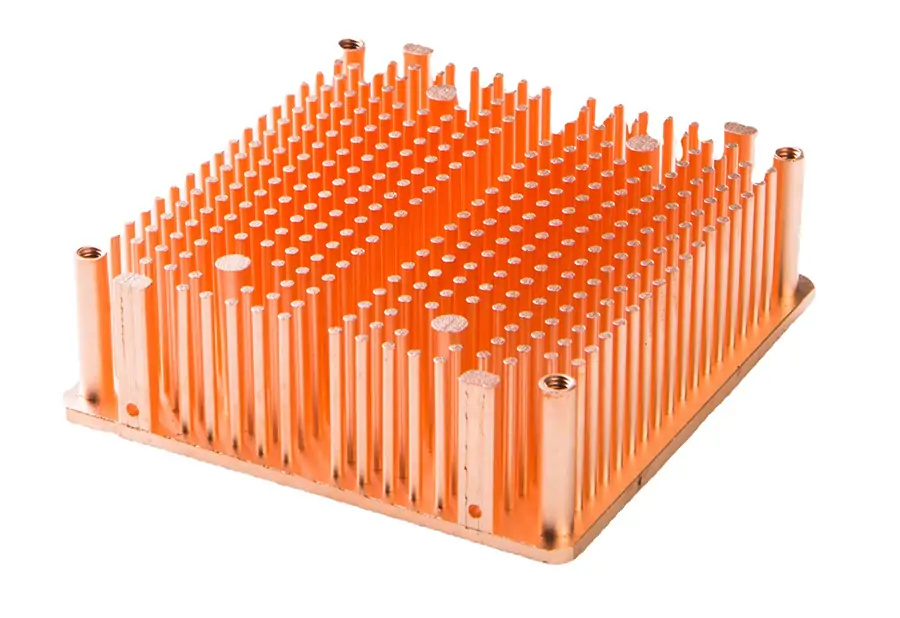

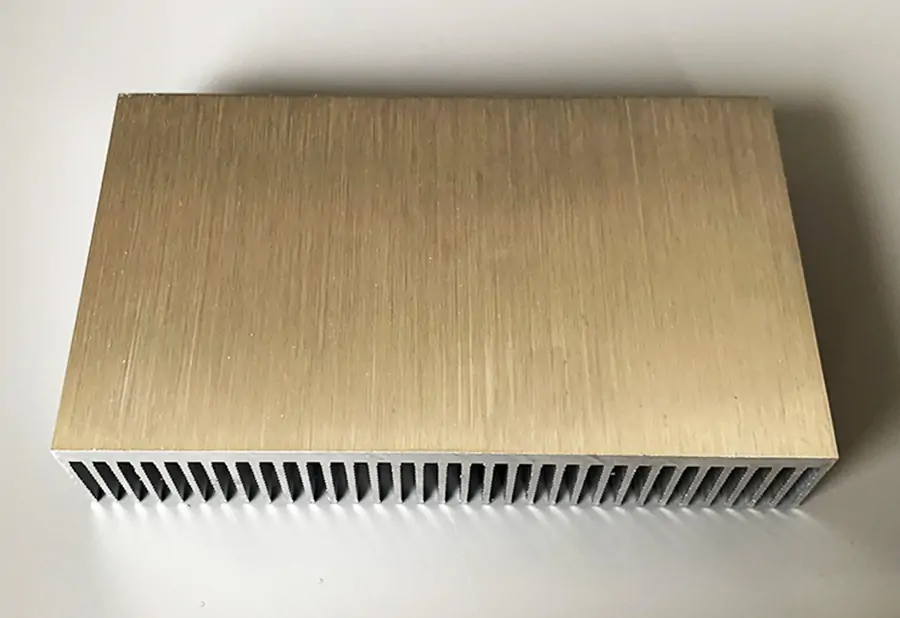

Pin heatsinks are typically made of materials with high thermal conductivity, such as aluminum or copper. The pins, which are closely spaced, are attached to the heat-generating component, such as a processor or a power transistor, using thermal adhesive or mechanical fasteners.

As the electronic component generates heat, the pin heatsink absorbs the heat through conduction. The heat then travels along the pins and is dissipated into the surrounding air through convection. The large surface area of the pins allows for efficient heat transfer, ensuring that the component stays within its safe operating temperature range.

Different Types of Pin Heatsinks

There are several different types of pin heatsinks available, each designed to meet specific cooling requirements. Some common types include:

1. Straight Pin Heatsinks: These heatsinks consist of straight pins that are evenly spaced. They are suitable for applications where space is limited.

2. Staggered Pin Heatsinks: Staggered pin heatsinks have pins that are arranged in a staggered pattern. This design provides better airflow and improves heat dissipation.

3. High-Density Pin Heatsinks: High-density pin heatsinks have a higher number of pins per unit area. They are ideal for applications that require maximum heat dissipation in a compact form factor.

4. Customized Pin Heatsinks: In some cases, custom-designed pin heatsinks may be required to meet specific cooling requirements. These heatsinks are tailored to the unique shape and dimensions of the electronic component.

Factors to Consider When Choosing a Pin Heatsink

When selecting a pin heatsink for a particular application, several factors need to be taken into consideration:

1. Thermal Resistance: The thermal resistance of a heatsink determines its ability to transfer heat. Lower thermal resistance is preferable for better cooling performance.

2. Heat Dissipation Area: The size and surface area of the heatsink should be appropriate for the heat generated by the electronic component. A larger heatsink with more pins will provide better cooling.

3. Material Selection: Different materials have varying thermal conductivity properties. Aluminum is commonly used for pin heatsinks due to its lightweight nature and good thermal conductivity.

4. Airflow Considerations: The surrounding environment and airflow conditions should be evaluated to ensure optimal heat dissipation. Proper ventilation and airflow management are crucial for effective cooling.

Benefits of Using Pin Heatsinks

The use of pin heatsinks offers several benefits for electronic devices:

1. Improved Performance: By effectively dissipating heat, pin heatsinks help maintain the optimal operating temperature of electronic components. This ensures consistent performance and prevents performance degradation due to overheating.

2. Extended Lifespan: Excessive heat can significantly reduce the lifespan of electronic devices. Pin heatsinks help prevent overheating, thereby increasing the longevity of the components and the overall device.

3. Compact Design: Pin heatsinks are lightweight and compact, making them suitable for applications where space is limited. Their small form factor allows for easy integration into various electronic devices.

4. Cost-Effectiveness: Pin heatsinks provide a cost-effective cooling solution compared to other methods such as liquid cooling. They are affordable, readily available, and easy to install.

Installation and Maintenance of Pin Heatsinks

Installing a pin heatsink requires careful consideration and proper technique to ensure effective heat dissipation. The following steps are generally involved in the installation process:

1. Clean the Surface: The surface of the electronic component should be free from dust, grease, or any other contaminants that may hinder proper heat transfer.

2. Apply Thermal Interface Material: A thin layer of thermal interface material, such as thermal paste or adhesive, should be applied between the component and the heatsink. This helps improve thermal conductivity and ensures efficient heat transfer.

3. Attach the Heatsink: The pin heatsink should be firmly attached to the component using either thermal adhesive or mechanical fasteners. The attachment method will depend on the specific heatsink design and the requirements of the application.

To maintain optimal performance, periodic inspection and cleaning of the pin heatsink are recommended.Accumulated dust and debris can reduce airflow and hinder heat dissipation. Regular maintenance will help ensure that the heatsink continues to function effectively.

Case Studies: Successful Use of Pin Heatsinks in Electronic Devices

Pin heatsinks have been widely used in various electronic devices to address heat dissipation challenges. Let's explore a few case studies that highlight their successful implementation:

1. Computer Processors: High-performance computer processors generate a significant amount of heat. Pin heatsinks, combined with cooling fans, are commonly used to keep the processors within their safe operating temperature range.

2. Graphics Cards: Graphics cards used in gaming and graphics-intensive applications can also generate substantial heat. Pin heatsinks are employed to dissipate this heat and prevent performance issues.

3. Power Supplies: Power supplies in electronic devices can generate heat during operation. Pin heatsinks are used to cool components such as transformers and voltage regulators, ensuring their reliable performance.

4. LED Lights: LED lights can produce heat that can affect their lifespan and efficiency. Pin heatsinks are employed to dissipate this heat, ensuring the longevity and optimal performance of the LEDs.

These case studies demonstrate the versatile application of pin heatsinks in various electronic devices,showcasing their effectiveness in managing heat dissipation.

Common Misconceptions About Pin Heatsinks

Despite their widespread use, there are some misconceptions surrounding pin heatsinks. Let's address a few common misconceptions:

1. Pin Heatsinks Are Only for High-Performance Devices: While pin heatsinks are commonly used in high-performance devices, they are also beneficial for lower-powered electronics. Any electronic device that generates heat can benefit from proper heat dissipation provided by pin heatsinks.

2. More Pins Always Mean Better Cooling: While a higher number of pins can provide increased surface area for heat dissipation, it is not always necessary for every application. The number of pins should be chosen based on the specific cooling requirements of the electronic component.

3. Pin Heatsinks Are Difficult to Install: Pin heatsinks are designed to be lightweight and easy to install. With proper instructions and techniques, they can be installed by anyone with basic technical skills.

Conclusion: The Future of Pin Heatsinks in Electronics

As electronic devices continue to evolve and become more powerful, the need for efficient heat dissipation becomes increasingly important. Pin heatsinks offer a reliable and cost-effective solution to address this challenge. Their compact design, effective heat transfer capabilities, and easy installation make them an essential component in a wide range of electronic devices.

As technology advances, we can expect further innovations in pin heatsink design and materials, leading to even more efficient heat dissipation solutions. By continuously improving heat management in electronics, we can ensure the longevity and optimal performance of our devices.

Unraveling the mystery behind pin heatsinks has shed light on their importance and the critical role they play in maintaining the performance and reliability of electronic devices. Whether it's a computer processor, a graphics card, or an LED light, pin heatsinks are the unsung heroes that keep our electronics cool and functioning at their best.

So, the next time you use your electronic device, take a moment to appreciate the pin heatsink silently working behind the scenes, keeping your device cool and ensuring it performs flawlessly.