Finned heat sinks, often referred to as "passive heat sink components" in the field of electronic engineering design, are commonly used for their excellent thermal conductivity, lightweight properties, and easy machining process. They attach to the heating surface to dissipate heat through a composite heat exchange mode.

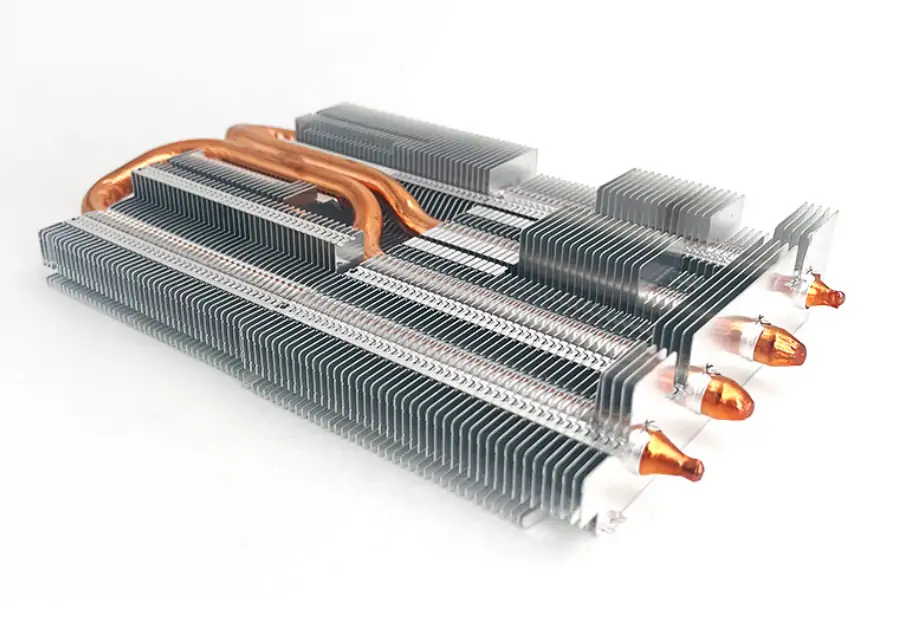

What does a finned heat sink look like? A type of heat sink fin includes a main body and two connecting parts. The main body has two fixed holes at its ends, a through hole in the middle, and a joint protruding from one side of the heat sink fin at the through-hole, allowing the heat sink fin to be joined with the heat pipe through the through hole and the connecting part. The connecting part is vertically extended from both ends of the main body, including a vertical part and a bearing part. The vertical part includes a first receiving block and two second receiving blocks. A first receiving portion is formed on both sides of the first receiving block, while a second receiving portion is formed between the second receiving blocks. The bearing part extends vertically inward from the second receiving part of the vertical part, parallel to the main body, and has two fixed protrusions corresponding to the fixed holes on the main body.

As we all know, CPU heat dissipation is mainly achieved through conduction, which involves the direct contact of the heat sink with the processor. After absorbing the heat, the heat sink dissipates it in a convective form. In the process of convective heat dissipation, the heat dissipation area is mainly determined by the surface area of the finned heat sink. The larger the surface area, the better the heat dissipation effect; the smaller the surface area, the worse the heat dissipation effect. Common measures in the industry include: increasing the number of finned heat sinks, increasing the length of finned heat sinks, which is reflected in a data called "thickness-height ratio", i.e., the ratio of the thickness and height of the heat sink fin. The smaller this value means that more finned heat sinks can be made per unit volume, the larger the effective heat dissipation surface area, and the better the heat dissipation performance.

Advantages of Finned Heat Sinks:

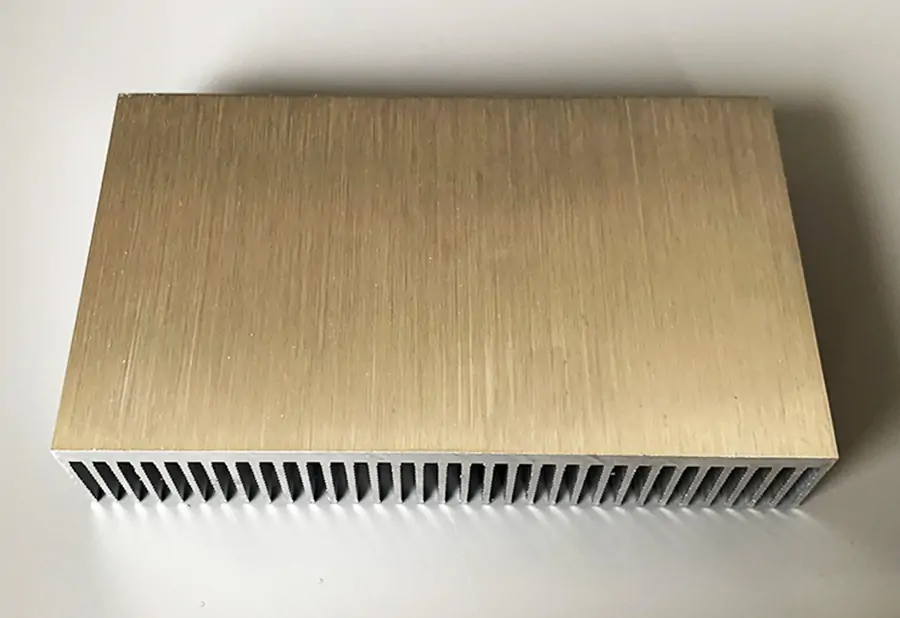

1.Large heat dissipation area, lightweight, fast convection, good heat dissipation, low temperature. (The junction temperature of a 3W lamp cup is at least 5 degrees lower than that of the same power die-cast aluminum heat sink, up to 11 degrees lower).

2.The material is 1060, 1050 high thermal conductivity aluminum sheet, with a maturity coefficient as high as 53, (the general extruded aluminum thermal conductivity coefficient is 40, die-cast aluminum thermal conductivity coefficient is 28).

3.There is no need to fill thermal conductive silicone in the heat sink, and the power supply heat dissipation method is unique.

4.The structure is easy to assemble and produces quickly.

5.The heat dissipation structure is light, only 60%-70% of the weight of die-cast aluminum.

6.The appearance is beautiful and generous, more high-grade and exquisite, and can be produced in various colors and surface treatment effects.

7.The finned heat sink lamp cup is stamping type, automatic assembly, no welding, fast production speed, good production process, and excellent quality.