Heat sinks play a crucial role in the efficient functioning of electronic devices by effectively regulating their temperature. Without proper temperature management, electronic components can overheat, leading to decreased performance and even permanent damage. In this article, we will explore the science behind how heat sinks work and why they are essential for the optimal performance and longevity of electronic devices.

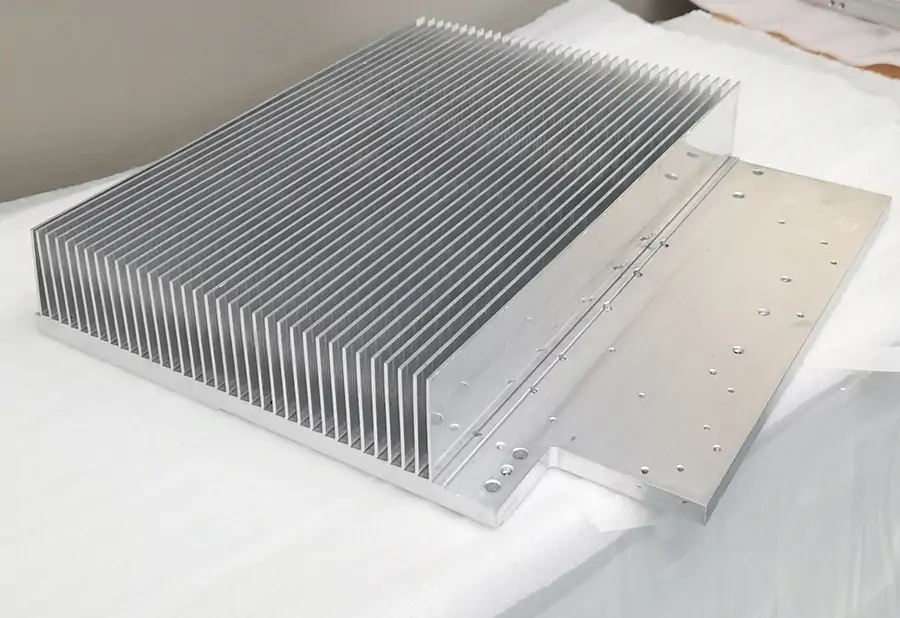

Heat sinks are designed to transfer heat away from electronic components and dissipate it into the surrounding environment. By increasing the surface area exposed to air, heat sinks facilitate the efficient transfer of thermal energy. This is achieved through a combination of materials with high thermal conductivity, such as copper or aluminum, and strategically placed fins or ridges that maximize heat dissipation.

Understanding the principles behind heat sinks is crucial for engineers, technicians, and anyone involved in the design and maintenance of electronic devices. By implementing effective heat sink designs, manufacturers can ensure that their devices operate within safe temperature limits, preventing performance issues and prolonging the lifespan of electronic components.

Join us as we delve into the fascinating world of heat sinks and uncover the science behind temperature regulation in electronic devices.

How Heat Sinks Work

Heat sinks are designed to transfer heat away from electronic components and dissipate it into the surrounding environment. By increasing the surface area exposed to air, heat sinks facilitate the efficient transfer of thermal energy. This is achieved through a combination of materials with high thermal conductivity, such as copper or aluminum, and strategically placed fins or ridges that maximize heat dissipation.

The basic principle behind heat sinks is conduction, where heat flows from a higher temperature region to a lower temperature region. When electronic components generate heat during operation, the heat is conducted through the base of the heat sink, which is in direct contact with the component. From there, the heat spreads through the metal and is dissipated into the air through the fins or ridges, which provide additional surface area for heat transfer.

The effectiveness of a heat sink depends on several factors, including the thermal conductivity of the material used, the size and shape of the fins, and the airflow around the heat sink. By optimizing these parameters,engineers can design heat sinks that efficiently dissipate heat and keep electronic devices within safe operating temperatures.

Importance of Heat Sinks in Electronic Devices

The importance of heat sinks in electronic devices cannot be overstated. As electronic components become smaller and more powerful, the amount of heat generated also increases. Without proper temperature regulation, the performance and reliability of electronic devices can be compromised.

One of the primary functions of a heat sink is to prevent thermal runaway, a phenomenon where the heat generated by electronic components exceeds the heat dissipation capabilities of the device. This can lead to a rapid increase in temperature, causing components to malfunction or even fail.

Heat sinks also help maintain consistent performance by preventing thermal throttling, a mechanism that reduces the operating frequency of components to prevent them from overheating. By dissipating heat effectively, heat sinks ensure that electronic devices can operate at their maximum potential without the risk of performance degradation.

Furthermore, heat sinks contribute to the longevity of electronic components. Excessive heat can cause the degradation of materials, leading to a shorter lifespan for electronic devices. By keeping temperatures within safe limits, heat sinks help preserve the integrity of electronic components, resulting in longer-lasting devices.

Heat Sink Materials and Designs

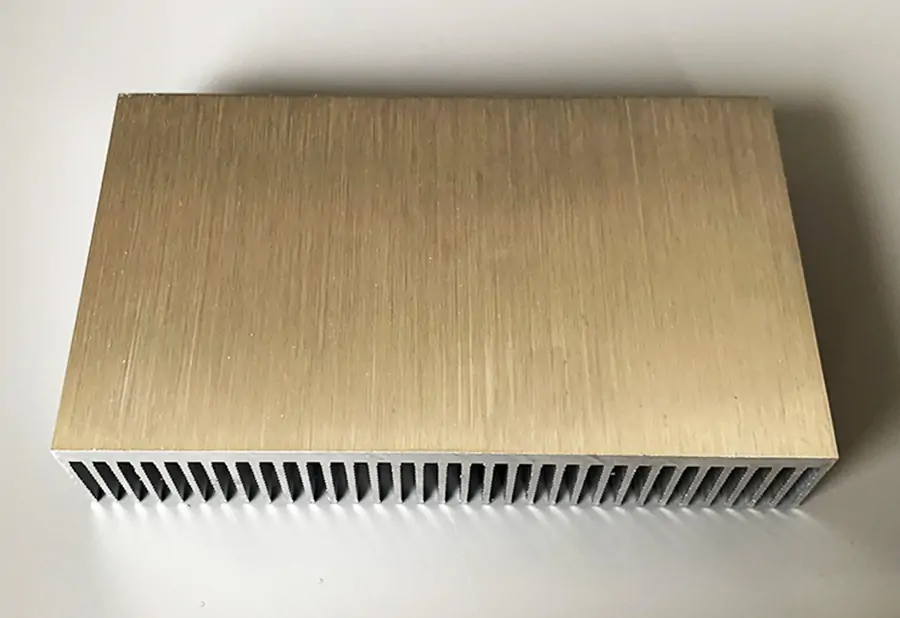

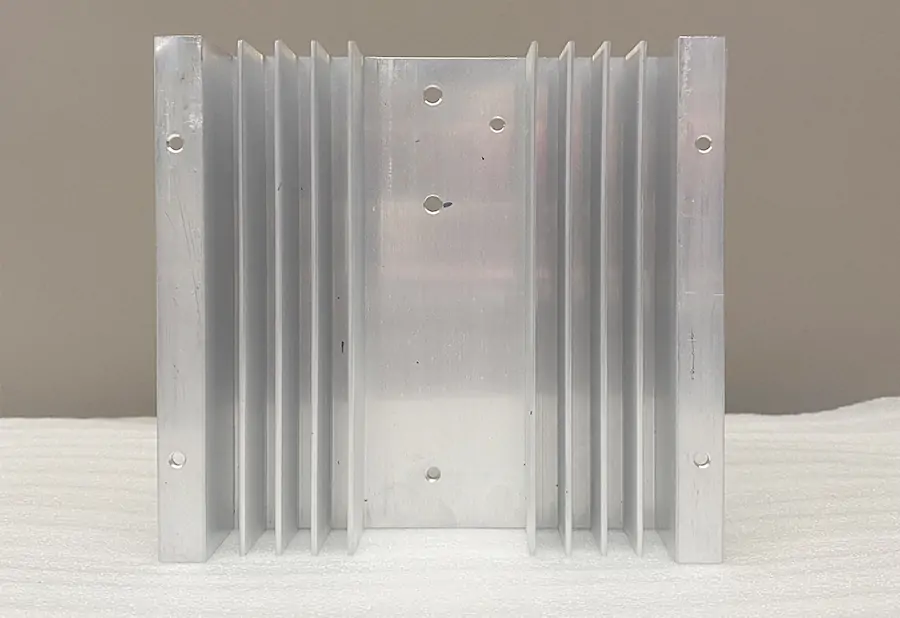

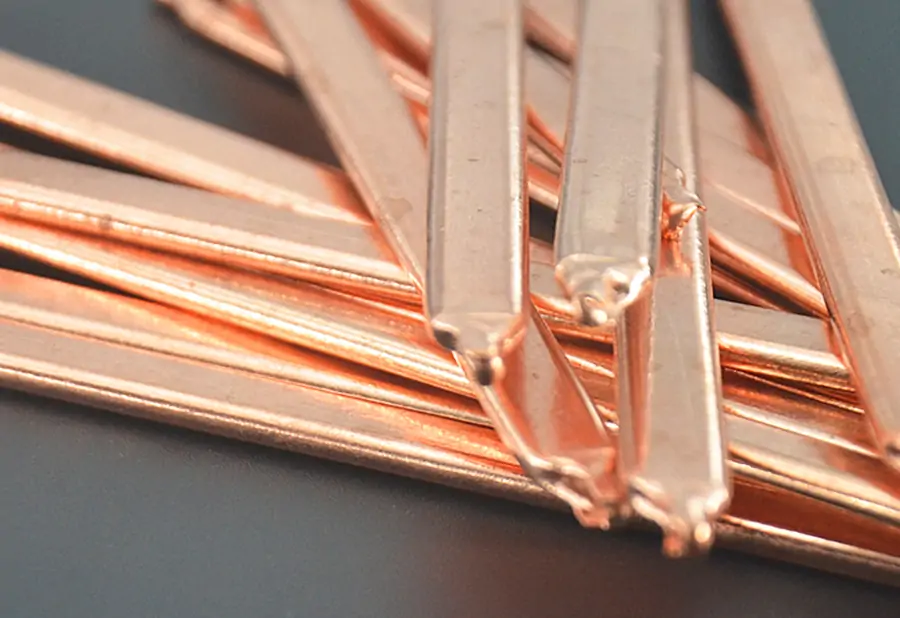

The materials used in heat sinks play a crucial role in their effectiveness. Copper and aluminum are commonly used due to their high thermal conductivity. Copper, in particular, has excellent thermal properties and is often used in heat sinks for high-performance applications. Aluminum, on the other hand, is lightweight and cost-effective, making it a popular choice for heat sinks in consumer electronics.

In addition to the materials used, the design of heat sinks also impacts their performance. The most common design features include fins or ridges, which increase the surface area available for heat dissipation. The shape and size of these fins can vary depending on the specific application and cooling requirements.

Another design consideration is the base of the heat sink, which is in direct contact with the electronic component. Increasing the contact area between the heat sink and the component improves heat transfer.Various methods, such as heat pipes or thermal interface materials, can be employed to enhance this contact and improve overall thermal performance.

Factors Affecting Heat Sink Performance

Several factors can affect the performance of a heat sink, and understanding these factors is crucial for designing effective cooling solutions. One of the primary considerations is airflow. Heat sinks rely on the circulation of air to dissipate heat, so ensuring a sufficient and consistent airflow is essential. This can be achieved through the use of fans or other cooling mechanisms.

The thermal resistance between the electronic component and the heat sink is another important factor.Lowering this resistance improves heat transfer and enhances overall cooling performance. Using high-quality thermal interface materials, such as thermal paste or pads, can help minimize this resistance and improve thermal conductivity.

The operating environment also plays a role in heat sink performance. Factors such as ambient temperature,humidity, and dust accumulation can impact the effectiveness of heat sinks. It is important to consider these factors during the design and installation of heat sinks to ensure optimal performance and reliability.

Choosing the Right Heat Sink for Your Device

Selecting the appropriate heat sink for a specific electronic device requires careful consideration of various factors. The power dissipation of the device, the available space for heat sink installation, and the required airflow are some of the key considerations.

The power dissipation, or the amount of heat generated by the electronic component, determines the thermal requirements of the heat sink. It is essential to choose a heat sink that can handle the specific power dissipation of the device to prevent overheating.

The available space for heat sink installation also determines the size and shape of the heat sink. It is important to ensure that the heat sink can fit within the device without obstructing other components or airflow paths.

Additionally, the required airflow for effective heat dissipation should be considered. This can be achieved through natural convection, forced convection using fans, or a combination of both. The heat sink should be designed to accommodate the desired airflow mechanism.

Common Heat Sink Installation Mistakes to Avoid

Proper installation of heat sinks is critical for their effectiveness. Unfortunately, several common mistakes are often made during installation, compromising the cooling performance of heat sinks.

Insufficient thermal interface materials or improper application of thermal paste can create air gaps between the heat sink and the electronic component, resulting in poor heat transfer. It is important to use the correct amount of thermal interface material and ensure proper contact between the surfaces.

Another common mistake is inadequate airflow. Heat sinks rely on a steady flow of air to dissipate heat, so it is crucial to ensure that the device's ventilation system is not obstructed. Cleaning the fins regularly and avoiding the accumulation of dust or debris can help maintain optimal airflow.

Improper mounting or securing of the heat sink can also lead to reduced cooling performance. It is essential to follow the manufacturer's guidelines for installation and use the recommended mounting hardware to ensure proper contact and stability.

Innovations in Heat Sink Technology

As electronic devices continue to advance, so does heat sink technology. Manufacturers are constantly innovating to improve heat sink performance, efficiency, and reliability.

One such innovation is the use of heat pipes in heat sink designs. Heat pipes are sealed copper tubes filled with a working fluid that transfers heat through evaporation and condensation. This technology enables more efficient heat transfer and can be particularly beneficial in applications with high power densities.

Another advancement is the integration of heat sinks into the design of electronic components themselves. This approach, known as embedded heat sinks, eliminates the need for separate heat sink assemblies and reduces the overall size and weight of electronic devices.

Additionally, researchers are exploring the use of advanced materials, such as carbon nanotubes or graphene,in heat sink designs. These materials have exceptional thermal properties and could potentially revolutionize heat sink technology in the future.

DIY Heat Sink Solutions for Electronic Devices

While there are numerous commercially available heat sinks for electronic devices, DIY solutions can also be effective in certain situations. For example, using an old CPU cooler as a heat sink for a small electronic device can provide sufficient cooling.

When considering a DIY heat sink solution, it is important to ensure proper compatibility and thermal performance. The heat sink should be appropriately sized, have good thermal conductivity, and be securely mounted to the electronic component.

Conclusion: The Future of Heat Sinks in Electronic Devices

Heat sinks are essential for the efficient temperature regulation of electronic devices. By effectively dissipating heat, they prevent performance issues, extend the lifespan of electronic components, and ensure optimal device operation.

As electronic devices continue to evolve, heat sink technology will also advance to meet the growing thermal demands. Innovations such as heat pipes, embedded heat sinks, and advanced materials hold promise for more efficient and compact cooling solutions in the future.

By understanding the science behind heat sinks and considering the specific requirements of electronic devices,engineers and technicians can design and implement effective cooling solutions to ensure the reliable and long-lasting operation of electronic devices.